AXIOMADE Syringe assembly machine

A syringe assembly machine automates the assembly of syringe components, ensuring precision and efficiency.

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- AXIOMADE

- Payment Terms

- D/A,D/P,L/C,MoneyGram,Others,T/T,Western Union

- Production method

- Available

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery & Industry Equipment

DONGWOO M TECHNO

- Membership

- VIP

- Recent Visit

- Jan 14, 2025

- Country / Year Established

-

South Korea

/

1995

South Korea

/

1995

- Business type

- Manufacturer

- Verified Certificate

-

7

| Product name | AXIOMADE Syringe assembly machine | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Material | - |

| Keyword | syringe , syringe assembly , syringe assembly machine , syringe assemblying machine | Unit Size | - |

| Brand name | AXIOMADE | Unit Weigh | - |

| origin | South Korea | Stock | 0 |

| Supply type | Available | HS code | - |

Product Information

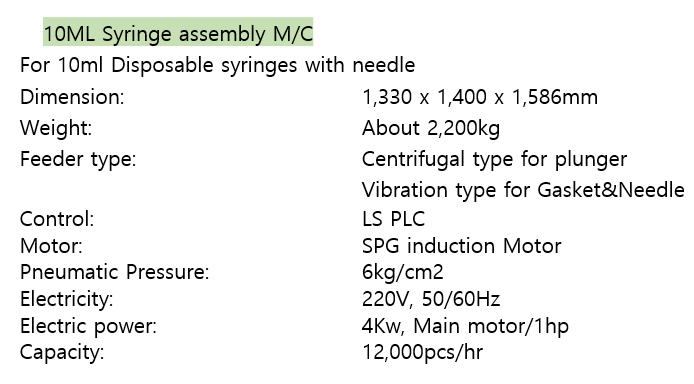

A syringe assembly machine is a sophisticated piece of equipment designed to automate the assembly of syringe components, ensuring precision, efficiency, and consistency in the manufacturing process. This machine integrates various stages of syringe production, combining multiple components into a fully functional syringe ready for packaging.

Components and Function:

The syringe assembly machine typically handles several key components: the barrel, plunger, rubber stopper, and needle. The process begins with the automatic feeding of these components into the machine. Each component is carefully aligned and assembled through a series of mechanical, pneumatic, or electronic mechanisms.

Barrel Insertion: The machine starts by positioning the barrel, which is the main body of the syringe, into the assembly line. This can involve feeding barrels from a hopper or conveyor system.

Plunger and Stopper Installation: Next, the plunger, which includes the piston and rod, is inserted into the barrel. A rubber stopper is also placed at the end of the barrel to create a seal, ensuring that the syringe can hold fluids without leakage.

Needle Attachment: For syringes that require needles, the machine then attaches the needle securely to the barrel. This step often involves precise alignment to ensure proper functionality and sterility.

Automation and Efficiency:

Syringe assembly machines are designed for high efficiency and precision. Automation reduces the need for manual labor, minimizing human error and increasing production speed. These machines often feature programmable controls that allow adjustments for different syringe sizes and types. Advanced models include quality control systems such as sensors and cameras that inspect each assembled syringe for defects or misalignment.

Benefits:

The use of a syringe assembly machine enhances overall production efficiency by speeding up the assembly process, ensuring consistent quality, and reducing labor costs. It also improves safety by minimizing direct human contact with the components, which is crucial for maintaining sterility and reducing contamination risks.

In summary, a syringe assembly machine is vital in modern manufacturing, streamlining the assembly process and ensuring that syringes meet high standards of quality and efficiency.

B2B Trade

| Price (FOB) | Negotiable | transportation | Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,MoneyGram,Others,T/T,Western Union | Shipping time | Negotiable |

- President

- JUNGPHIL LEE

- Address

- 209ho Technozone, 117 Hwanggeum-ro , Gimpo-si, Gyeonggi-do, KOREA

- Product Category

- Medical Devices

- Year Established

- 1995

- No. of Total Employees

- 1-50

- Company introduction

-

Dongwoo M Techno is a customer and quality oriented manufacturer of various needle products. Since its establishment it has exported its products to more than 50 countries and built its reputation as a reliable supplier of high quality products. With years of accumulated knowledge in quality management system and production technology, all products manufactured by Dongwoo M Techno as well as its facilities are GMP ISO quality certified

- Main Markets

-

Germany

Germany

Russia

Russia

U. Kingdom

U. Kingdom

- Main Product

,_Smartphone_dryer,_heating_mobile_2.jpg)