AXIOMADE Blister packing and auto loader

Blister packing secures syringes in plastic blisters, while auto loaders automate syringe insertion into packaging.

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- AXIOMADE

- Payment Terms

- D/A,D/P,L/C,MoneyGram,Others,T/T,Western Union

- Production method

- Available

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- auto loader, machine, syringe, blister packaging

- Category

- Other Machinery & Industry Equipment

DONGWOO M TECHNO

- Membership

- VIP

- Recent Visit

- Jan 14, 2025

- Country / Year Established

-

South Korea

/

1995

South Korea

/

1995

- Business type

- Manufacturer

- Verified Certificate

-

7

| Product name | AXIOMADE Blister packing and auto loader | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | auto loader , machine , syringe , blister packaging | Unit Size | - |

| Brand name | AXIOMADE | Unit Weigh | - |

| origin | South Korea | Stock | 0 |

| Supply type | Available | HS code | - |

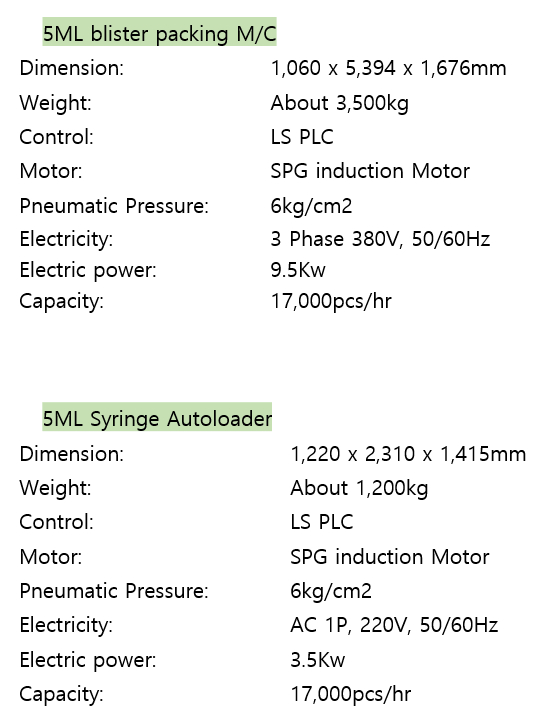

Product Information

Blister packing and auto loaders are crucial components in the syringe assembly line, enhancing efficiency, safety, and packaging quality.

Blister Packing:

Blister packing involves enclosing syringes in pre-formed plastic blisters, which are often made from materials like PVC or PET. This process begins with the formation of blister cavities, where each syringe is placed. The machine then heat-seals a lidding material, usually aluminum foil, over the blister pack, creating a secure and tamper-evident package. Blister packing offers several advantages, including protection from contamination, physical damage, and environmental factors. The clear plastic allows for easy visibility of the syringe, aiding in quality checks and ensuring that the product is easily identifiable. This method also extends the shelf life of the syringes by providing a barrier to moisture and air.

Auto Loader:

The auto loader is an automated system designed to streamline the insertion of syringes into blister packs or other types of packaging. This machine typically integrates with the syringe assembly line and operates in a synchronized manner to improve workflow efficiency. Syringes are fed into the auto loader, which then automatically aligns, positions, and inserts them into the blister cavities or packaging slots. This automation reduces manual handling, decreases the risk of contamination, and enhances overall production speed. The auto loader often features adjustable settings to accommodate different syringe sizes and packaging formats. Additionally, it includes sensors and controls to ensure precise placement and to minimize errors or misalignment.

Together, blister packing and auto loaders significantly enhance the efficiency and safety of the syringe assembly line. Blister packing provides secure, visible, and protective packaging, while auto loaders automate the insertion process, reducing labor and improving productivity. Both components are integral to modern syringe manufacturing, ensuring high standards of quality and reliability in the final product.

B2B Trade

| Price (FOB) | Negotiable | transportation | Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,MoneyGram,Others,T/T,Western Union | Shipping time | Negotiable |

- President

- JUNGPHIL LEE

- Address

- 209ho Technozone, 117 Hwanggeum-ro , Gimpo-si, Gyeonggi-do, KOREA

- Product Category

- Medical Devices

- Year Established

- 1995

- No. of Total Employees

- 1-50

- Company introduction

-

Dongwoo M Techno is a customer and quality oriented manufacturer of various needle products. Since its establishment it has exported its products to more than 50 countries and built its reputation as a reliable supplier of high quality products. With years of accumulated knowledge in quality management system and production technology, all products manufactured by Dongwoo M Techno as well as its facilities are GMP ISO quality certified

- Main Markets

-

Germany

Germany

Russia

Russia

U. Kingdom

U. Kingdom

- Main Product