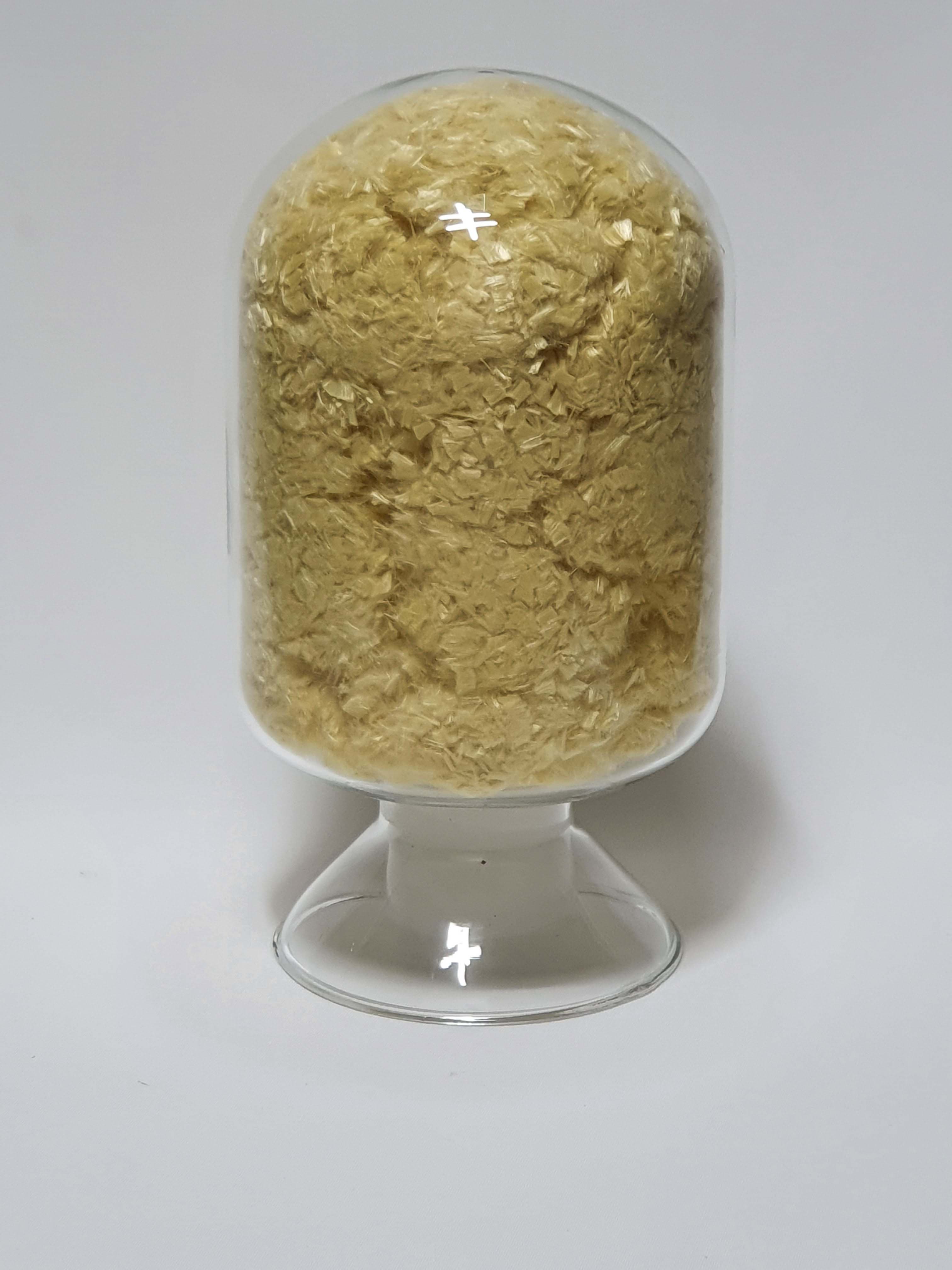

Chopped Fiber for Material Reinforcement -Aramid, Carbon Fiber, Glass Fiber, Lyocell, PVA, PET, etc.

Chopped Fiber for Material Reinforcement (for Rubber belt, Engineering plastic, Ultra High Performance Concrete(UHPC))

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- Chopped Fiber for Material Reinforcement

- Payment Terms

- L/C,Others,T/T

- Production method

- Available,ODM,OEM

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- material, reinforcement, chopped steel fiber, chopped fiber

- Category

- Other Fiber

MISUNG POLYMER INC.

Exhibition 2

PREVIEW IN SEOUL & InterCHARM Korea Expo 2023- Verified Certificate

-

4

| Product name | Chopped Fiber for Material Reinforcement -Aramid, Carbon Fiber, Glass Fiber, Lyocell, PVA, PET, etc. | Certification | - |

|---|---|---|---|

| Category | Other Fiber | Material | ARAMID FIBER,CARBON FIBER,GLASS FIBER |

| Keyword | material , reinforcement , chopped steel fiber , chopped fiber | Unit Size | - |

| Brand name | Chopped Fiber for Material Reinforcement | Unit Weigh | - |

| origin | South Korea | Stock | 100 |

| Supply type | Available,ODM,OEM | HS code | 560130 |

Product Information

Established in 1999, Misung Polymer supplies reinforced cord, reinforced chopped fiber, and reinforced fabric using fiber surface treatment technology to many domestic and foreign companies. We mainly produce chopped fibers for material reinforcement in various fields such as rubber industry, plastic industry, and concrete industry.

As a specialized company in fiber surface treatment and precision chopping, we are producing chopped fibers through the process of chopping after coating and heat-treating the surface of industrial fibers with resin.

1. Chopped fibers for Rubber Belt Reinforcement.

Chop fibers are used in many ways, from low-load rubber belts to medium/high-load rubber belts.

In particular, rubber belts used for high-load agricultural machines such as combine and tractors have high heat generation during operation and have to endure impact caused by sudden load. Therefore, it requires high resistance to abrasion.

Rubber belt products made from chopped fibers reinforced rubber can maintain strength, heat resistance, impact resistance and abrasion resistance even under high loads.

2. Chopped fibers for Engineering Plastic Reinforcement.

Even plastics, the most commonly encountered material in our daily life, can be used together with chopped fibers to enhance strength and improve abrasion resistance.

Chopped fibers reinforced plastics can be applied to various resins such as PP, PE, ABS, PA (Nylon), and can be used without any problem in the extrusion and injection process.

Chopped fiber reinforced plastics are used in manufacturing automobile interior and exterior materials, as well as electronic device cases, mechanical parts, and furniture.

3. Chopped fiber for Ultra-High Performance Concrete (UHPC) Reinforcement.

These days, there is an increasing demand for infrastructure and structures that are larger, higher-rise, atypical, taller, and long lasting Chopped fiber is known as the most suitable material for realizing these properties of concrete. Recently, the demand for ultra-high performance concrete (UHPC) containing steel fibers or chopped fibers has increased rapidly. So we have developed various types of single or composite hybrid chopped fibers and are supplying them to several many of companies.

In particular, we have 4 patents for chopped fiber for concrete reinforcement.

As a specialized company in fiber surface treatment and precision chopping, we are producing chopped fibers through the process of chopping after coating and heat treating the surface of industrial fibers with resin.

- Fibers: Aramid, Carbon fiber, Glass Fiber, Lyocell, PVA, PET, PP and etc.

- Dipping Polymer: RFL, Amide, Silane, Epoxy, PU, PET and etc.

- Chop Length: 1~999 mm, by 0.1 mm unit

* Most chopped fiber products are custom-made so we consult with customers for their desired fibers, resins, and chopped lengths.

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | Air Transportation,Express,Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,Others,T/T | Shipping time | Negotiable |

- President

- Youn Byoung Soo

- Address

- 96 Gimhae-daero 916beon-gil Hallim-myeon Gimhae-si Gyeongnam, Gimhae-si, Gyeongsangnam-do, Korea

- Product Category

- Concrete,Other Fiber,Other Rubber Raw Materials,Plastic Building Materials

- Year Established

- 1999

- No. of Total Employees

- 1-50

- Company introduction

-

Misung Polymer Inc. is specialized in the fiber surface treatment and precision Chopping.

We coat various resins on fiber surface with the heat treatment, and produce the preciously chopped fiber

which is used as composite for various industrial materials like rubber, engineering plastic, ultra high performance concrete(UHPC).

[ Business Field ]

1. Fiber Surface Treatment

1) Chopped-Fiber for Material Reinforcment

- For Rubber / Engineering Plastic / Ultra High Performance Concrete(UHPC)

(Chop length: 1~999mm, 1mm increment)

2) Reinforced Cord

3) Reinforced Fabric

[ History ]

1999 Established company (Misung polymer).

2001 2-Dipping heat treatment facility expansion for Rubber hose reinforcement cord(yarn) (#1 unit-18TON/month).

2002 Factory relocation (HALLIM-MYEON).

2003 Quality certification from PET & NYLON-66 Dipping for medium and high pressure rubber hoses.

2006 ISO 9001:2000 certification.

2008 Quality Certification of PVA Dipping Yarn for brake hose (AutoPart).

2009 Quality certification of ARAMID Dipping yarn for rubber belt.

2010 FIBER CUTTING facility construction.

2011 Acquired Patent No.10-0948243 (Method to manufacture carbon coating fiber for plane type heating element).

2012 AIR BLEED YARN quality certification for tire manufacturing.

2012 4-Dipping heat treatment facility expansion for Rubber belt reinforcement cord(yarn). (#2-10TON/month).

2013 Development of CHOP FIBER for reinforcing rubber and engineering plastics.

2014 Development of adhesive resin for EPDM rubber & rubber boat.

2016 NICE-Information-Service Certified as an excellent technology evaluation company .

2017 Development of chop fiber for reinforced super concrete.

2017 Development of Hose for AIR SUSPENSION.

2017 Quality certification of Conductive AIR BLEED YARN for tire manufacturing

2017 Establishment of new department(Research & Development Dept.).

2018 Acquired Patent No.10-1887814 (bundle-type short fibers for fiber reinforced concrete and fiber Reinforced

concrete using thereof).

2018 Acquired Patent No.10-1887815 (bundle-type short fibers for fiber reinforced concrete using conjugate fiber and

fiber Reinforced concrete using thereof).

2018 Corporate conversion(Misung Polymer Inc.).

2019 Waterproof Coating Resin Development.

2020 ISO 14001:2015 certification.

- Main Markets

-

China

China

Hungary

Hungary

Indonesia

Indonesia

Russia

Russia

U.S.A

U.S.A

Viet Nam

Viet Nam

- Main Product

- Attached File

Related Products

Arselon flame retardant staple fiber

POLYESTER STAPLE FIBER LOW MELT FIBER

PM PLC Splitter Module

BROWN-BLACK FIBER

pp multifilament yarn of high tenacity

South Korea

South Korea

_2.jpg)