Disaster and safety cleanliness

It can be washed without power off, and there is no residue left due to eco-friendly products, non-corrosive substances, and natural evaporation.

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- L/C,T/T

- Production method

- Available

- Shipping / Lead Time

- Negotiable / Negotiable

Mirae Tech

- Verified Certificate

-

16

| Product name | Disaster and safety cleanliness | Certification | - |

|---|---|---|---|

| Category |

Electrical Instrument

Cleaning Equipment & Parts Electrical Plugs & Sockets Motor Parts |

Ingredients | - |

| Keyword | uninterruptible cleaner , electronic cleaning , equipment protection , extend machine life , prevention of electrical accidents | Unit Size | 330.0 * 280.0 * 250.0 mm |

| Brand name | - | Unit Weigh | 13 kg |

| origin | South Korea | Stock | 50 |

| Supply type | Available | HS code | 2710199000 |

Product Information

D&SCLEAN's DS55 model is a 550ml spray type that allows anyone to easily clean electronic equipment, communication equipment, and voltage panels while live. It is an eco-friendly product free of freon gas and ozone-destructing substances, non-corrosive substances that do not damage electronic components, evaporates naturally, and operates comfortably for a long time by adding harmless lemon scent.

The DS180 model DS180 model uses dedicated cleaning equipment to remove fine dust and dust through 22.9kv, special high pressure, various high pressure panels (ACV, VCB, MCCB) and high pressure transformers.

1. Using Products

- Mobile Base Station Advanced Equipment PCB Assembly

- Circuit board of manufacturing product lines for semiconductor and electrical products such as LCD, PDP and TV (CCTV, Monitor, OPC, PLC, Air Cleaner, Telephone, Cooler, Audio, Fax, Printer, VTR, Camcorder, Mobile, MP3, Digital Camera, etc.)

- Maintenance and management of electronic communication equipment such as optical communication

- Mechanical equipment and components, motors, automotive electronic components

2. Effects

Since electrical fires such as insulation destruction caused by deterioration of semiconductors are more than 30% and the industry's average cost of power outages is KRW 256.3 million (1,000Kw/1 day), uninterruptible live insulation cleaning is required.

- Allow cleaning in uninterrupted live conditions to improve work efficiency and productivity - Technical precision cleaning to protect facilities and extend life - Clean fine parts apartments to create a safe working environment - Green cleaning prevents malfunction and improves operational efficiency.

- Electrical, electronic and communication equipment can be cleaned while active.

(Use eco-friendly cleaning solutions for basic cleaning power and environmental consideration)

1. Agility - power down, time and manpower savings

Safe and fast cleaning without 2. Economical - Economic effects of cleaning to fine parts, protection of equipment, extension of life, etc.

3. Permeability - Permeability, failure and fire penetrating complex and fine parts of the facility

Complete cleaning of dust and debris for prevention 4. Environment - Made and used non-toxic solvents made from natural lemons

No poetry Ozone depletion 5. Safety - no chemical or material damage to the facility that is harmless to the human body.

- Excellent degreasing

- Non-chlorite, fluoride

- Non-Conductive: 25,000 V

- Includes Natural Citris Solvents

- Activity: 100% clear color and thin viscosity water

- Flash Point: 144°F (62 C)

- Variability is safer than solvent.

- Specific gravity: 0.767 gr / cc

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | Air Transportation,Ocean Shipping |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Hee Cheon Park

- Address

- 26, Hyojagl-gil, Gunbuk-myeon, Haman-gun, Gueongsangnam-do,Korea

- Product Category

- Electricity Generation

- Year Established

- 2008

- No. of Total Employees

- 1-50

- Company introduction

-

Mirae Tech Co., Ltd. has been incorporated in 2008 to manufacture and distribute tower flange for wind power generator and other general & heavy industrial equipment. Now we has jumped in developing wind power generation system with starting 500W hybrid ( wind & solar ) power system for theme park, golf course etc.

We are confident that our company will satisfy client's various demands and expectations even under the rapidly changing circumstances. We will make the world a more beautiful and enriching through eco-friendly products.

- 2008 May Registered as an excellent venture company.

- 2009 Jan Established "Affiliated Research & Development Center"

- 2009 Jun Participated as member of "Wind Power Generating Core Technical Lab"

- 2010 Jun Certification of ISO 9001 & 14001

- 2011 Nov Registered a Patent of Wind Power Generating System

- Main Markets

-

Australia

Australia

Canada

Canada

N.Zealand

N.Zealand

U.A.E.

U.A.E.

U.S.A

U.S.A

- Factory Information

-

MIRAE TECH Co,.Ltd.,

R&D Center,

Seoul Office

- Main Product

Related Products

Emergency Switchboard (ESBD)

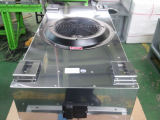

Golf Steam Cleaner

Modbus Device Recorder

Fan Filter Unit /FFU

Atomatic ultrasonic cleaning system - Spray type

South Korea

South Korea