Thermal Gap Filler For Battery Pack Thermal Management

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- GLPOLY

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

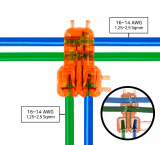

- gap filler, thermal gap filler, two- component

- Category

- Other Electronic Components

Thermal Interface Materials

- Verified Certificate

-

9

| Product name | Thermal Gap Filler For Battery Pack Thermal Management | Certification | - |

|---|---|---|---|

| Category | Other Electronic Components | Ingredients | - |

| Keyword | gap filler , thermal gap filler , two- component | Unit Size | - |

| Brand name | GLPOLY | Unit Weigh | 1 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | 3926 |

Product Information

GLPOLY Thermal gap filler has been applying in military equipment shown in parade, it’s no doubt that GLPOLY thermal gap filler will be applied in volume production by the major auto companies.

Many auto companies requested to use thermal gap filler instead of thermal gap pad this. In the study of thermal gap filler application status, we found that many faults came out such as slump, sag or break in dispensing gap filler, even uncuring in 24hrs.

There is no any abnormal situation since GLPOLY thermal gap filler XK-S20 has been applying in new energy vehicle of X brand, neither in trial and volume production. It proved that GLPOLY thermal gap filler XK-S20 provides high stability and reliability.

I can say GLPOLY thermal gap filler is so confident and excellent,

GLPOLY will process raw materials with nano-scale grinder, optimizing material conbination, nobody else is behaving like this in China.

GLPOLY introduced automated production system that eliminates artifical error and keep consistency of product in trial or volume.

GLPOLY entrusted CTI to test reliability, high temperature aging 1000hrs and high temperature&humidity 1000hrs, all indexes met requirements. When we submitted the report to customer, he was surprised and said this is the most complete test report he had received.

Our peers only deliver gap filler while we provide thermal gap filler and corollary dispensing equipment together for customers, along with 24-7 assistance and guidance. When ours peers are providing thermal gap filler with 1-3W/mK of thermal conductivity, GLpoly is delivering reliable and stable thermal gap filler with 5.0W/mK.

Curing time is crucial to customer because it affects productivity. Usually, for most of suppliers even the top brand abroad, curing time of thermal gap filler is 24 hours in room temperature, however, GLpoly had improved curing time by 70%, it means that thermal gap filler(thermal silicone adhesive) will cure in 4-6hours in the same condition.

GLpoly is able to customize the data of viscosity, hardness and density etc of thermal silicone adhesive(thermal gap filler) to meet customers’ special requirements on battery pack thermal management.

In Dec 2019, several senior mangers from a Japanese-owned auto enterprise in Gangzhou had visited GLpoly Dongguan factory. After observing and studying the automated production line and product inspection process, they had satisfied with results and cancelled the visit plan to another thermal gap filler manufacturer.

Another car manufacturer in Beijing had decided to investigate GLpoly for a volume production project in 2020. Four major auto enterprises have been trying GLpoly thermal gap filler(thermal adhesive) XK-S20, as founder of GLpoly said, 2020 is a year worth striving for.

GLpoly is confident that thermal gap filler(thermal adhesive) XK-S20 is the preferred thermal management solution to new engery vehicle battery pack for many auto enterprises.

GLPOLY Thermal gap filler has been applying in military equipment shown in parade, it’s no doubt that GLPOLY thermal gap filler will be applied in volume production by the major auto companies.

Many auto companies requested to use thermal gap filler instead of thermal gap pad this. In the study of thermal gap filler application status, we found that many faults came out such as slump, sag or break in dispensing gap filler, even uncuring in 24hrs.

There is no any abnormal situation since GLPOLY thermal gap filler XK-S20 has been applying in new energy vehicle of X brand, neither in trial and volume production. It proved that GLPOLY thermal gap filler XK-S20 provides high stability and reliability.

I can say GLPOLY thermal gap filler is so confident and excellent,

GLPOLY will process raw materials with nano-scale grinder, optimizing material conbination, nobody else is behaving like this in China.

GLPOLY introduced automated production system that eliminates artifical error and keep consistency of product in trial or volume.

GLPOLY entrusted CTI to test reliability, high temperature aging 1000hrs and high temperature&humidity 1000hrs, all indexes met requirements. When we submitted the report to customer, he was surprised and said this is the most complete test report he had received.

Our peers only deliver gap filler while we provide thermal gap filler and corollary dispensing equipment together for customers, along with 24-7 assistance and guidance. When ours peers are providing thermal gap filler with 1-3W/mK of thermal conductivity, GLpoly is delivering reliable and stable thermal gap filler with 5.0W/mK.

Curing time is crucial to customer because it affects productivity. Usually, for most of suppliers even the top brand abroad, curing time of thermal gap filler is 24 hours in room temperature, however, GLpoly had improved curing time by 70%, it means that thermal gap filler(thermal silicone adhesive) will cure in 4-6hours in the same condition.

GLpoly is able to customize the data of viscosity, hardness and density etc of thermal silicone adhesive(thermal gap filler) to meet customers’ special requirements on battery pack thermal management.

In Dec 2019, several senior mangers from a Japanese-owned auto enterprise in Gangzhou had visited GLpoly Dongguan factory. After observing and studying the automated production line and product inspection process, they had satisfied with results and cancelled the visit plan to another thermal gap filler manufacturer.

Another car manufacturer in Beijing had decided to investigate GLpoly for a volume production project in 2020. Four major auto enterprises have been trying GLpoly thermal gap filler(thermal adhesive) XK-S20, as founder of GLpoly said, 2020 is a year worth striving for.

GLpoly is confident that thermal gap filler(thermal adhesive) XK-S20 is the preferred thermal management solution to new engery vehicle battery pack for many auto enterprises.

GLPOLY Thermal gap filler has been applying in military equipment shown in parade, it’s no doubt that GLPOLY thermal gap filler will be applied in volume production by the major auto companies.

Many auto companies requested to use thermal gap filler instead of thermal gap pad this. In the study of thermal gap filler application status, we found that many faults came out such as slump, sag or break in dispensing gap filler, even uncuring in 24hrs.

There is no any abnormal situation since GLPOLY thermal gap filler XK-S20 has been applying in new energy vehicle of X brand, neither in trial and volume production. It proved that GLPOLY thermal gap filler XK-S20 provides high stability and reliability.

I can say GLPOLY thermal gap filler is so confident and excellent,

GLPOLY will process raw materials with nano-scale grinder, optimizing material conbination, nobody else is behaving like this in China.

GLPOLY introduced automated production system that eliminates artifical error and keep consistency of product in trial or volume.

GLPOLY entrusted CTI to test reliability, high temperature aging 1000hrs and high temperature&humidity 1000hrs, all indexes met requirements. When we submitted the report to customer, he was surprised and said this is the most complete test report he had received.

Our peers only deliver gap filler while we provide thermal gap filler and corollary dispensing equipment together for customers, along with 24-7 assistance and guidance. When ours peers are providing thermal gap filler with 1-3W/mK of thermal conductivity, GLpoly is delivering reliable and stable thermal gap filler with 5.0W/mK.

Curing time is crucial to customer because it affects productivity. Usually, for most of suppliers even the top brand abroad, curing time of thermal gap filler is 24 hours in room temperature, however, GLpoly had improved curing time by 70%, it means that thermal gap filler(thermal silicone adhesive) will cure in 4-6hours in the same condition.

GLpoly is able to customize the data of viscosity, hardness and density etc of thermal silicone adhesive(thermal gap filler) to meet customers’ special requirements on battery pack thermal management.

In Dec 2019, several senior mangers from a Japanese-owned auto enterprise in Gangzhou had visited GLpoly Dongguan factory. After observing and studying the automated production line and product inspection process, they had satisfied with results and cancelled the visit plan to another thermal gap filler manufacturer.

Another car manufacturer in Beijing had decided to investigate GLpoly for a volume production project in 2020. Four major auto enterprises have been trying GLpoly thermal gap filler(thermal adhesive) XK-S20, as founder of GLpoly said, 2020 is a year worth striving for.

GLpoly is confident that thermal gap filler(thermal adhesive) XK-S20 is the preferred thermal management solution to new engery vehicle battery pack for many auto enterprises.

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Mr. Kang

- Address

- Rm619, Huafeng Xinan Commercial Bulding, Baoan, Shenzhen China

- Product Category

- Other Electronic Components

- Year Established

- 1998

- No. of Total Employees

- 51-100

- Company introduction

-

GoldlinkTongda Electronics Co., Ltd is committed to thedesign, development and manufacture of Thermal Interface Materials, developing high qualityTIMs and Thermal Solution isour first priority. Our outstanding R&D team are ableto deliver the effective thermal solutions to customers for facing currentadvanced products.

Products

Ourbusiness includes Silicone Thermal Pad, Silicone Rubber Pad, Silicone PuttyPad, Silicone Thermal Tape, Thermal Interface Grease, Two-part Thermal InterfaceSealing Compound, Silicone Thermal Gel, Thermal Interface Phase Change Materialsand Non-Silicone type products.

Applications

We serve a multitude of industries worldwide includingNew energy vehicles, UAV,computer,telecommunications, consumer electronics, opticalproducts, LEDlighting, air flight, storage device, military and medicalequipment, powerconversion.

- Main Markets

-

China

China

Germany

Germany

U. Kingdom

U. Kingdom

U.S.A

U.S.A

- Main Product