Prefabricated building/furniture non-welding frame

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- The Cube System

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- assemble frame, frame, furniture frames, construcion materials

The Cube System

- Country / Year Established

-

South Korea

/

2016

South Korea

/

2016

- Business type

- Manufacturer

- Verified Certificate

-

5

| Product name | Prefabricated building/furniture non-welding frame | Certification | - |

|---|---|---|---|

| Category |

Construction Tools

Other Constructions Furniture Frames & Legs Agricultural Greenhouses Construction Material Stocks Formwork Metal Building Materials Stairs & Handrails |

Ingredients | - |

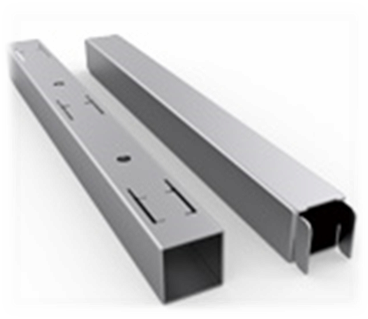

| Keyword | assemble frame , frame , furniture frames , construcion materials | Unit Size | 5.0 * 5.0 * 100.0 cm |

| Brand name | The Cube System | Unit Weigh | 1 kg |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 8311 |

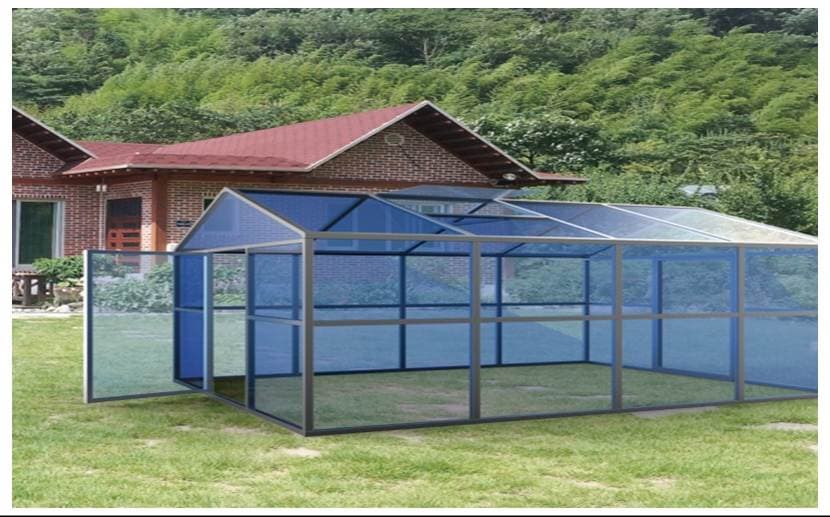

Product Information

We The Cube System is using various metal frame assembly construction methods to design, construct, operate and manage in general for the household furnitures and buildings, etc.

The Cube System is the specialized company for the Non-welding frame design and

manufacturing.

The Cube System’s unique design with the related patent on frame connection structure

eliminates the need of the frame welding in architectural design.

By removal of welding process, the limited factors in building construction are disappeared andadditionally gave the advantages.

Assembled non-welding frame is a compound research which is made based on Mathematics / Physics / Structural Mechanics / Assembly / Architecture, etc.

Non-welding system understands the character and structure of iron and has been verified by many experiments and tests. Only The Cube System who has the outstanding technical skills, domestic and global patents is capable of manufacturing the perfect assembled non-welding products.

Combining mode for mold

It is the combining mode for mould which is developed for the mass-production of correct size products.

The Cube System is based on the self-developed system, using the laser to manufacture the vertical materials and using press molding to manufacture the horizontal materials.

Can manufacture with reduced time and the thickness of vertical/horizontal materials are reasonable, the manuacturing speed and size is accuraten and with perfect structure calculation have no problem with construction of exterior panels on building.

Cross coupling connection

For Precision assembly

Vertical frame – Laser cutting

Horizontal frame – Laser cutting

Hook coupling connection

For mass production

Skilled laborer not required

Cost effective

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- PARK JONG GIL

- Address

- 70 Gasan digital 1-ro Geumcheon-gu Seoul, Geumcheon-gu, Seoul, Korea

- Product Category

- Construction Tools,Formwork,Furniture Frames & Legs,Metal Building Materials,Mouldings

- Year Established

- 2016

- Company introduction

-

The Cube System Co., Ltd. is the specialized company for the non-welding frame design and manufacturing.

The Cube System’s unique design with the related patent on frame connection structure eliminates the need of the frame welding in architectural design.

By removal of welding process, the limited factors in building construction are disappeared and additionally some advantages are given.

1) Corrosion resistance due to no use of the traditional welding process.

2) Easy assembly by low skilled laborer.

3) Assembly time and the Labor cost reduction.

4) Safe working environment by no using of welding equipment

5) Reusable by easy dismantled and re-assembly.

6)Shipping cost saving by component level shipping rather than fully assembled

structure.

- Main Product

Related Products

Thermal Bench

RC Level Rod

Prefabricated Light Weight Steel Building

Finger Joint Lumber Board

High Refraction High Diffusion Dot Printing Ink for LGP

_2.png)