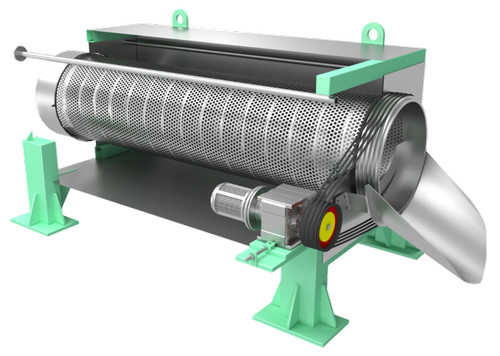

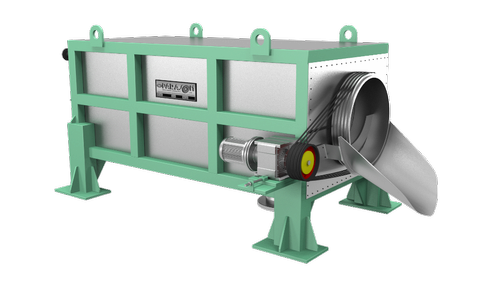

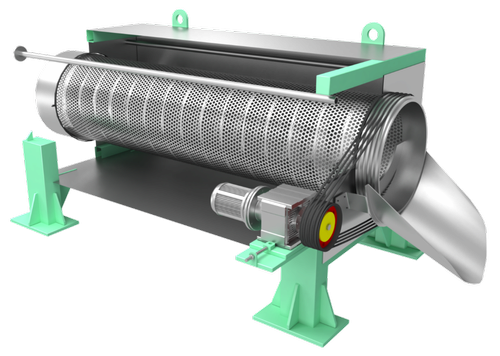

Trommel Screen - Pulp & Paper Machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- India

- Brand name

- Parason

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- trommel screen

- Category

- Paper Processing Machines Parts

PARASON MACHINERY (INDIA) PRIVATE LIMITED

- Verified Certificate

-

7

| Product name | Trommel Screen - Pulp & Paper Machine | Certification | - |

|---|---|---|---|

| Category | Paper Processing Machines Parts | Ingredients | - |

| Keyword | trommel screen | Unit Size | - |

| Brand name | Parason | Unit Weigh | - |

| origin | India | Stock | - |

| Supply type | - | HS code | - |

Product Information

Parason produces the most durable and efficient trommel screens in the pulp & paper industry. Using a revolving screened cylinder to accomplish the separation of material by size, our trommel screens are ideal for Construction and Demolition waste, Municipal Solid Waste, Green Waste and Waste to Energy front-end separation systems.

Our trommel screens are positioned at the beginning of the equipment line, replacing the need for multiple pieces of equipment. All our trommel screens are engineered with an energy efficient design that utilizes gravity and centrifugal force to separate different material sizes from the waste stream.

Features -

- Easy Installation

- Perforated drum of SS-304, drive arrangement, inside helical screw, out let chute of SS-304 and Supporting Structure of M.S.

- Drum is driven through Geared Motor, Pulleys and Belts

- C-I drive and driven pulleys properly machined

- Shower pipe with nozzles of SS-304

Application -

- For separating fibers and large coarse contaminants from the recycled fiber pulp after the Pulper

- Special heavy duty perforated drum allowing the recovery of fibers and rejecting the coarse contaminants, accepts returned to the Pulper

- Works as a Secondary Coarse Screen and installed in Pulper reject/accept line depending on type of Pulper & contaminants

Working Principles -

The Trommel is an rotating perforated drum. Contaminants and fibers fed into the Trommel screen from one end.To increase fiber recovery, the Trommel is slowly rotated to agitate the stock, water is added through shower provided to aid the fiber/ contaminants separation, large contaminants are rejected from the system as the helical screws welded inside the drum, force them out from order end of the Trommel.

The suitable hole size of the perforated drum is selected to optimize the separation properties and fiber recovery qualities. The accept from the Trommel containing fiber, water and small contaminants collected in the tray by gravity and feed back to the Pulper.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Shekhar Desarda

- Address

- 28 Parason House, Anukrupa, No.28, Venkatesh Nagar, Aurangabad 431001 INDIA

- Product Category

- Paper Processing Machines Parts,Paper Product Machines

- Year Established

- 1977

- No. of Total Employees

- 501-1000

- Company introduction

-

Parason Group is one of the largest manufacturer & Supplier of pulp and paper machinery. Renowned scientist & metallurgist Dr. Desarda is Founder & Chairman of the Company. Parason started its first research unit for pulp and paper machinery in the Year 1977.

Parason is focused on Research & Development. Many researches done by Parason shown that latest technology proposed by Parason not only enables Paper Mills to increase its Paper quality but also reduces huge power consumptions of machines which is the key point of Profit for Paper Industry. Parason offered products are widely used by Kraft, Tissue, Writing Printing and Hard Board Paper Mills. Parason also have specialization in Refiner Discs and these are one of best disc available for Paper mills across the globe. Parason manufactures various products which can be used for number of operations in stock preparation.

Parason have global consultancy services, which supports organization to setup New Paper Mills and also helps existing Paper Mills to archive higher goals. Parason also have international consultants based in Germany, Europe and USA.

Parason have worldwide client base and having majority market in Germany, USA, France, Thailand, Italy, Brazil, Spain, Portugal, Philippines, Indonesia, and Bangladesh, Parason serving more than 60 countries across world. Parason has successfully completed many installations for Paper Mills ranging from 25TPD to 400TPD.

- Main Product

India

India