Screen Plate - For Pulp and Paper Mill

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- India

- Brand name

- Parason

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- screen plate

- Category

- Paper Processing Machines Parts

PARASON MACHINERY (INDIA) PRIVATE LIMITED

- Verified Certificate

-

7

| Product name | Screen Plate - For Pulp and Paper Mill | Certification | - |

|---|---|---|---|

| Category | Paper Processing Machines Parts | Ingredients | - |

| Keyword | screen plate | Unit Size | - |

| Brand name | Parason | Unit Weigh | - |

| origin | India | Stock | - |

| Supply type | - | HS code | - |

Product Information

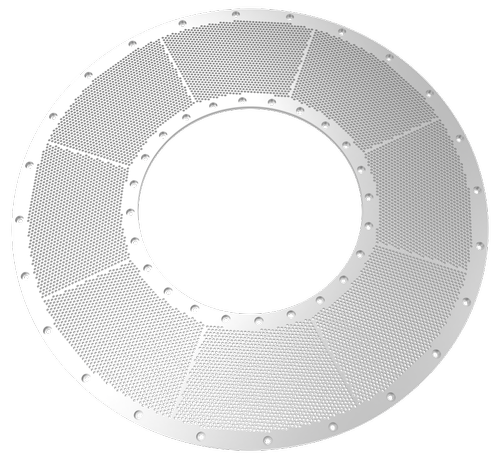

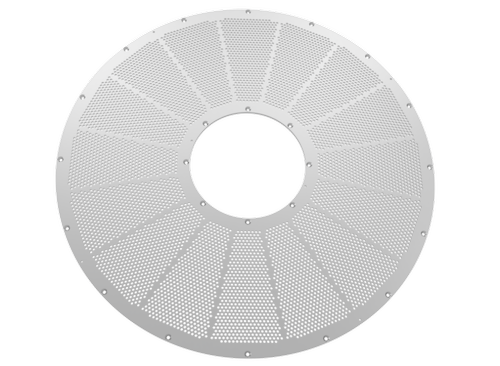

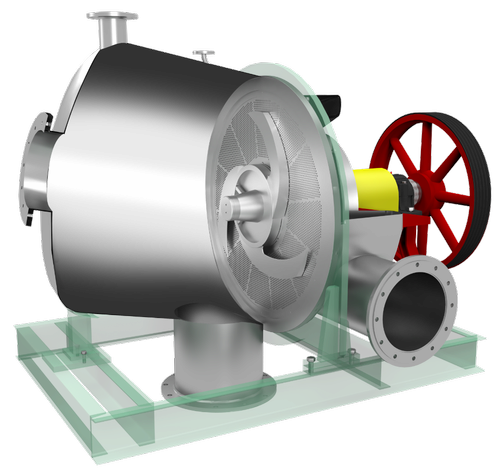

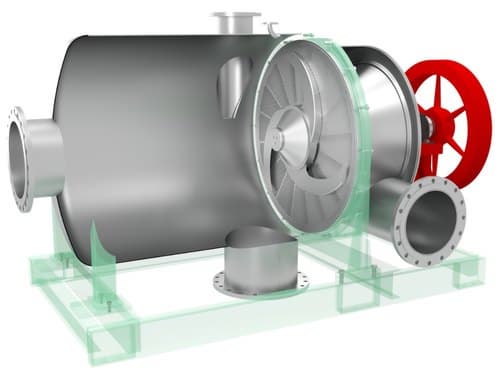

Screen plate is used in the screen basket. Screening equipment is an important operational system for pulp processing. Screen plate is situated in pulper. The stator and rotor are placed on the screen plate. Pulper has a rotor inside the machine that grinds and mixes the pulp evenly.

The pulp is made of fiber material obtained from trees and other waste material like office paper, newspaper, vegetable fiber, etc. all the fiber is taken to the pulper machine and is cut down into small pieces and mixed with water. The waste fiber contains contaminants, also the uncut fiber is separated with the help of the screen plate.

Contaminants may damage the product as well as the machine. It is necessary to separate the contaminants from pulp to get efficient results.

Screen plate work as a strainer that separates large, uncut particles from pulp to separate and collect them to other containers. The pulp is passed through the strainer for further procedure. Contaminants stay collected on screen plate and don’t mix with the pulp. Screen plate works continuously into the water. Therefore, it has to be made by corrosion resistance material.

The pulp is the main constituent of manufacturing paper, which collects the cellulose fiber from fiber material. Everyday use of paper has increased as the paper is easy to dispose of and does not harm the environment. The pulp is manufactured in tons every day, as the paper pulp is used to make paper bags, paper products, etc. As there is growth in the use of paper, paper industries are also growing.

Paper industries used fiber material to manufacture pulp such as wood fiber is the main constituent of manufacturing paper. As the increase in global warming, cutting down trees are not possible, that can affect the environment. Waste fiber can be used to make paper pulp, where they can also give the same result as that of the wood fiber.

Parason screen plate is made of stainless steel as it has to work continuously in water. Screen plate is easy in installation and has a long life. Screen plate works efficiently into pulper and separates the contaminants from the pulp.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Shekhar Desarda

- Address

- 28 Parason House, Anukrupa, No.28, Venkatesh Nagar, Aurangabad 431001 INDIA

- Product Category

- Paper Processing Machines Parts,Paper Product Machines

- Year Established

- 1977

- No. of Total Employees

- 501-1000

- Company introduction

-

Parason Group is one of the largest manufacturer & Supplier of pulp and paper machinery. Renowned scientist & metallurgist Dr. Desarda is Founder & Chairman of the Company. Parason started its first research unit for pulp and paper machinery in the Year 1977.

Parason is focused on Research & Development. Many researches done by Parason shown that latest technology proposed by Parason not only enables Paper Mills to increase its Paper quality but also reduces huge power consumptions of machines which is the key point of Profit for Paper Industry. Parason offered products are widely used by Kraft, Tissue, Writing Printing and Hard Board Paper Mills. Parason also have specialization in Refiner Discs and these are one of best disc available for Paper mills across the globe. Parason manufactures various products which can be used for number of operations in stock preparation.

Parason have global consultancy services, which supports organization to setup New Paper Mills and also helps existing Paper Mills to archive higher goals. Parason also have international consultants based in Germany, Europe and USA.

Parason have worldwide client base and having majority market in Germany, USA, France, Thailand, Italy, Brazil, Spain, Portugal, Philippines, Indonesia, and Bangladesh, Parason serving more than 60 countries across world. Parason has successfully completed many installations for Paper Mills ranging from 25TPD to 400TPD.

- Main Product

Related Products

Automatic Pile Turner

Wet Tissue ( Wipes ) Making and Packing Machines

_2.jpeg)

Cutting Rules(Center Bevel,Long Center Bevel ,Double Bevel.)

Paper Tube Cutter

spool roll for paper machine

India

India