ceramic nonstick coating material

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- amorscoat

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- ceramic coating cookware, ceramic coating machine, nonstick coating, ceramic coating material

- Category

- Coating & Paint

Baishan TechNet

- Membership

- VIP

- Recent Visit

- Jan 21, 2025

- Country / Year Established

-

South Korea

/

2002

South Korea

/

2002

- Business type

- Manufacturer

- Verified Certificate

-

17

| Product name | ceramic nonstick coating material | Certification | - |

|---|---|---|---|

| Category | Coating & Paint | Ingredients | - |

| Keyword | ceramic coating cookware , ceramic coating machine , nonstick coating , ceramic coating material | Unit Size | - |

| Brand name | amorscoat | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 3209901019 |

Product Information

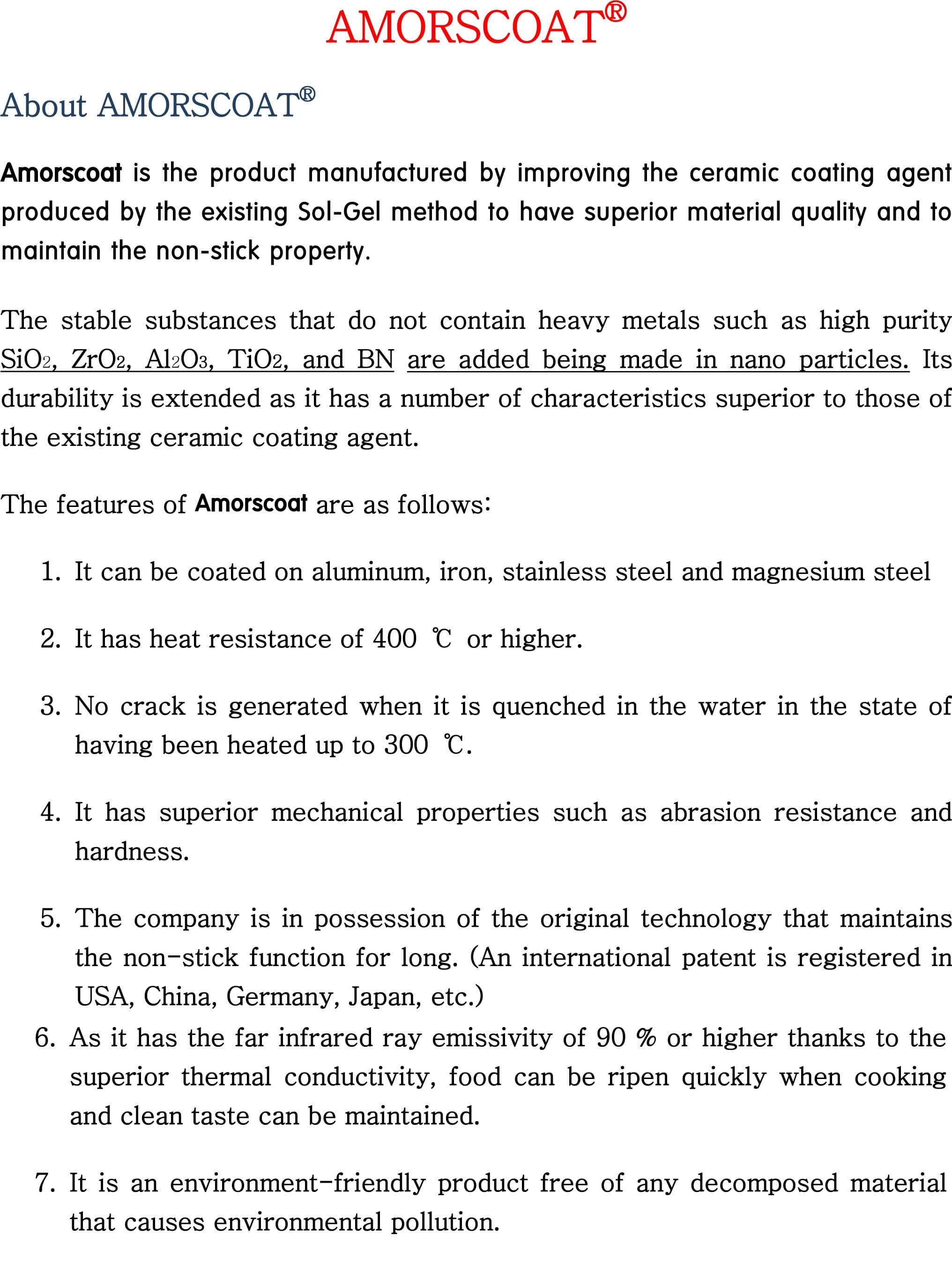

Amorscoat is the product manufactured by improving the ceramic coating agent

produced by the existing Sol-Gel method to have superior material quality and to

maintain the non-stick property.

The stable substances that do not

contain heavy metals such as high purity SiO2, ZrO2, Al2O3, TiO2, and BN are

added being made in nano particles.

Its durability is extended as it has

a number of characteristics superior to those of the existing ceramic coating

agent.

The features of Amorscoat are as follows:

1. It can be

coated on aluminum, iron, stainless steel and magnesium steel

2. It has heat

resistance of 400 ℃ or higher.

3. No crack is generated when it is quenched

in the water in the state of having been heated up to 300 ℃.

4. It has

superior mechanical properties such as abrasion resistance and hardness.

5.

The company is in possession of the original technology that maintains the

non-stick function for long. (An international patent is registered in USA,

China, Germany, Japan, etc.)

6. As it has the far infrared ray emissivity of

90 % or higher thanks to the superior thermal conductivity, food can be ripen

quickly when cooking and clean taste can be maintained.

7. It is an

environment-friendly product free of any decomposed material that causes

environmental pollution.

☆The characteristics of the fine ceramic nonstick coating☆

1. It is useful for replacing and upgrade the porcelain enamel coating and Teflon PTFE coating.

2. The hardness is strong to 9H.

3. It has nonstick function so that the

food and dust does not cling to the surface of coating.

Also it is easy to be washed.

4. Anti-bacteria substance can be added. So, the anti-bacteria coating possible.

5. It is nonflammability in fire event and not release the toxic gas.

6. heat conductivity

: The high thermal conduction makes the

thermal efficiency high. So, it is good for heating system.

save energy for heating.

7. heat emission : The heat can go faraway.

: It is very useful for the heater.

On the ceiling the ceramic coated heater is hung, the heat is go upto the

ground floor.

So, in the vinyl house and the agricultural crops in winter very useful and

effective.

8. far-infrared radiation

: The far-infrared radiation wave is good for health.

9. water resistance : It is strong for water resistance.

10. salt water resistance

11. acid resistance

12. heat resistance

: The normal ceramic coating can stand 400~500 centigrade, but some ceramic coating can be borne up to 700, 800, 1000 centigrade degree.

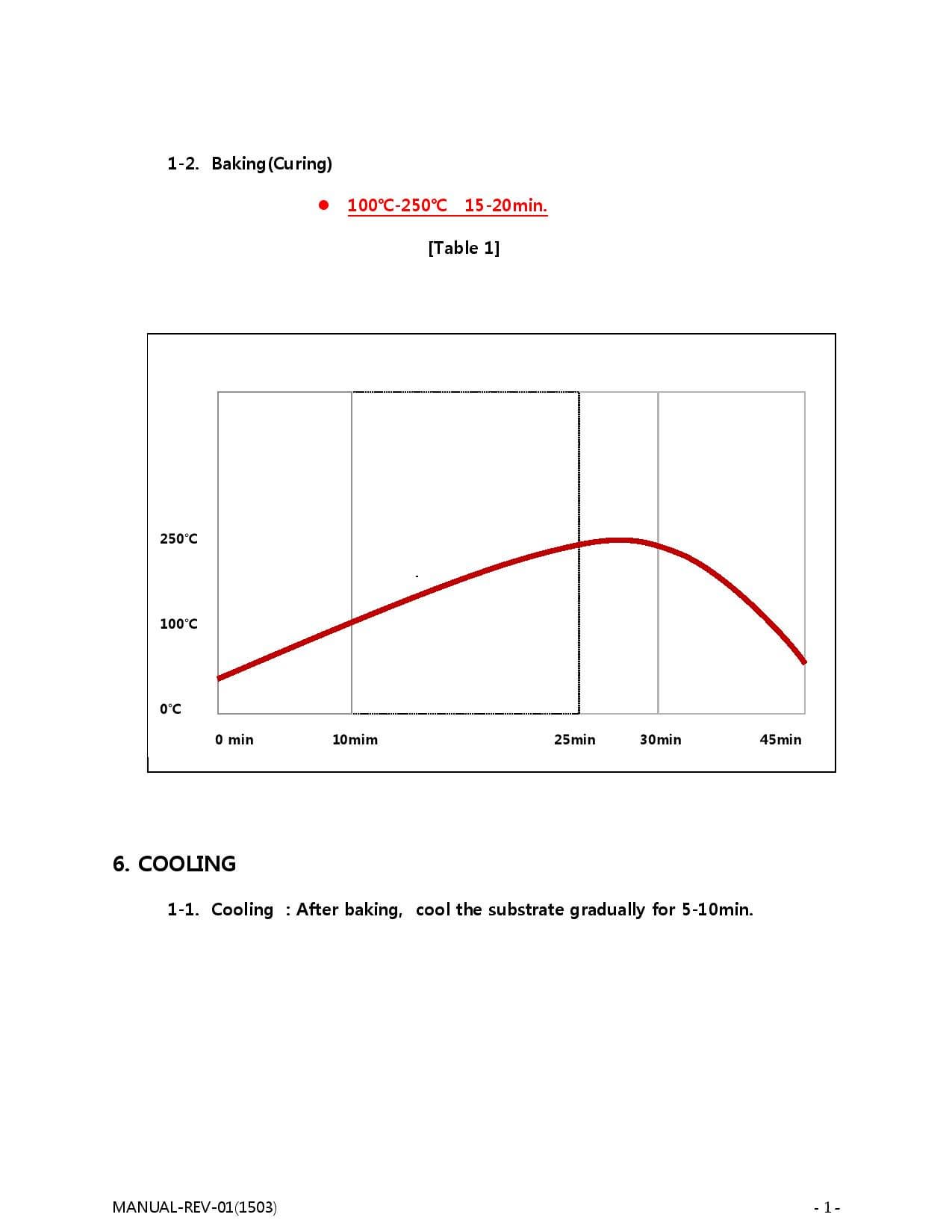

☆Ceramic coating process☆

A. on metal surface

: The aluminum is best suitable, but stainless steel or steel available for ceramic coating.

1) sand blasting : making sand blast for

penetrate the coating material liquid well.

2) Preheating around 50 centigrade (The temperature can be different, according

to metals.

3) Auto spraying : mixed liquid coating : base coating and top coating

4) baking : Put into the heating system up to 220 centigrade.

☆application field for ceramic coating☆

1. heat drying room

: for example, When the ceramic coating is done in the agricultural crop drying room, the crop can not be changed the color and faster dryness.

2. kitchenware (household goods)

: The ceramic coating is strong and nonstick so that the food is not cling to the surface and washing it easily. It is good taste the food due to far-infrared radiation.

3. The coating on the interior or exterior of the building

: It can be coated by spraying on the cement and wood wall.

Nonstick function : The dust is not easy to cling to the wall and easy to clean by water.

Anti-bacteria : on the interior It can be anti-bacteria treatment such as hospitals, baby, old people facilities.

4. It is useful for the heater. : high

thermal efficiency, heating go faraway.

far-infrared radiation for good health.

Baishan TechNet , Seoul Korea

How to use the ceramic coating material

There are two kinds of coating material.

One is for “base coating” in blue label.

The other is for “top coating” in red

label.

1. Base

A liquid (round plastic container) : Roll

at 100RPM for 30minutes ~1 hour.

So, the color can be mixed well.

(Blue

label A + Blue label B : mixing together. Red label A + Red label B : mixing

together)

2. Pour all of Base B liquid (flat

square plastic container) into Base A round container.

And then roll at 100RPM the mixed round container of Base coating for 16 ~18

hours

3. Before spraying it, filter Base

coating material with 300 mesh and Top

coating material with 150 mesh.

4. Spray the Base coating and then the Top coating on the Base coating in wet.

5. The ratio of spraying for Base coating

and Top coating is 3:1.

So, the Base coating is 3 times more thickness than Top coating.

The total thickness of ceramic coating will be suitable for 30 ~ 35 micron.

If too thickness of coating, it can be crack. So, you may adjust and check the

coating thickness.

6. Preheating the clean pot body (dust off, degrease) at 40 ~ 50 centigrade.

7. Spray with the nozzle of 1.0 ~ 1.2 micron.

8. Baking : 50 ~ 100 centigrade for about 10 minutes and then 200 ~ 250 centigrade for 15 ~ 20 minutes. The thicker pot is better at 250 centigrade.

9. Outside pot coating firstly and then inside pot coating. Or as you want.

10. After using the rest mixed coating material, it can be put into the refrigerator at 5 ~ 10 centigrade within 3 ~ 4 days.

11. Without mixing the coating material, it can be kept at 15 ~ 20 centigrade for about 3 months.

★ For granite

(marble) coating

The air pressure can be reduced to make the spots coating.

1. Base coating 2. Spots coating 3. Top coating 4. Baking

☆The characteristics of the fine ceramic nonstick coating☆

1. It is useful for replacing and upgrade the porcelain enamel coating and Teflon PTFE coating.

2. The hardness is strong to 9H.

3. It has nonstick function so that the food and dust does not cling to the surface of coating.

Also it is easy to be washed.

4. Anti-bacteria substance can be added. So, the anti-bacteria coating possible.

5. It is nonflammability in fire event and not release the toxic gas.

6. heat conductivity

: The high thermal conduction makes the thermal efficiency high. So, it is good for heating system.

save energy for heating.

7. heat emission : The heat can go faraway.

: It is very useful for the heater.

On the ceiling the ceramic coated heater is hung, the heat is go upto the ground floor.

So, in the vinyl house and the agricultural crops in winter very useful and effective.

8. far-infrared radiation

: The far-infrared radiation wave is good for health.

9. water resistance : It is strong for water resistance.

10. salt water resistance

11. acid resistance

12. heat resistance

: The normal ceramic coating can stand 400~500 centigrade, but some ceramic coating can be borne up to 700, 800, 1000 centigrade degree.

☆Ceramic coating process☆

A. on metal surface

: The aluminum is best suitable, but stainless steel or steel available for ceramic coating.

1) sand blasting : making sand blast for penetrate the coating material liquid well.

2) Preheating around 50 centigrade (The temperature can be different, according to metals.

3) Auto spraying : mixed liquid coating : base coating and top coating

4) baking : Put into the heating system up to 220 centigrade.

☆application field for ceramic coating☆

1. heat drying room

: for example, When the ceramic coating is done in the agricultural crop drying room, the crop can not be changed the color and faster dryness.

2. kitchenware (household goods)

: The ceramic coating is strong and nonstick so that the food is not cling to the surface and washing it easily. It is good taste the food due to far-infrared radiation.

3. The coating on the interior or exterior of the building

: It can be coated by spraying on the cement and wood wall.

Nonstick function : The dust is not easy to cling to the wall and easy to clean by water.

Anti-bacteria : on the interior It can be anti-bacteria treatment such as hospitals, baby, old people facilities.

4. It is useful for the heater. : high thermal efficiency, heating go faraway.

far-infrared radiation for good health.

Baishan TechNet , Seoul Korea

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Paul Lim

- Address

- 302 Liebe Baum 47 Achasan-ro 78gil Kwangjin-gu, Gwangjin-gu, Seoul, Korea

- Product Category

- Car Cleaning Tools,Cereals,Cookware & Cooking Tools,Face Mask,Washing Machines

- Year Established

- 2002

- No. of Total Employees

- 1-50

- Company introduction

-

We have been to develop and supply the car mat washing &drying machines in Korea since 1997.

We have various models of car mat cleaner. water gushing with brush &drying system for all kinds of car mats.

dry mat cleaner available also.

We can supply your brand or your own design of machine, also.

We are sure to give the satisfaction to you, even new developedmachine for yourself.

Pls kindly inform us of your any questions on the car washingmachine.

We are ready to cooperate you entirely and promptly.

We have experienced in the car washing machines professionally.

When you contact us, we are grateful to provide the details for your interested products.

We are sure we can supply our selective unique items and full professional experiences to make the fruitful business for mutual benefits in long term.

Looking forward to hearing from you at your earliest convenience.

Paul Lim / CEO

Baishan TechNet

- Main Markets

-

Australia

Australia

Canada

Canada

Germany

Germany

Netherland

Netherland

U.S.A

U.S.A

- Main Product

- Attached File

Related Products

UNISON AIR MOUNTS (UAM)

Sports Athletics Track System

Architectural Paints

Eco-friendly water based aserosol spray paint - COLORISMO

Peelable VCI Liquid GVL400