Injection molding machine for Biodegradable anchor pin

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- Biojet-2

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- injection mold machine, biodegradable anchor, sutures anchor, biodegradabe resign injection machine

- Category

- Medical Consumables , Surgical Equipment

i-SSAN Engineering

- Verified Certificate

-

13

| Product name | Injection molding machine for Biodegradable anchor pin | Certification | - |

|---|---|---|---|

| Category |

Medical Consumables

Surgical Equipment |

Ingredients | - |

| Keyword | injection mold machine , biodegradable anchor , sutures anchor , biodegradabe resign injection machine | Unit Size | 700.0 * 1700.0 * 1700.0 mm |

| Brand name | Biojet-2 | Unit Weigh | 500 kg |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

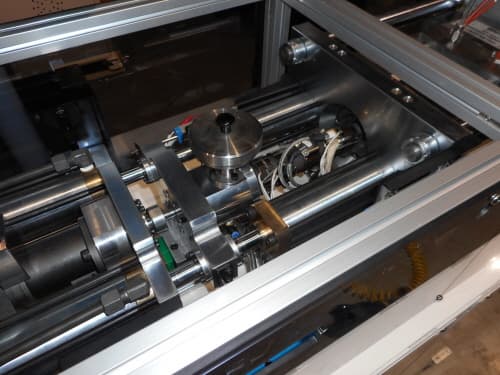

Model : Biojet-2 (Injection Volume 2cc)

: Biojet-5 (Injection Volume 5cc)

Micro sized but high power injection molding machine for;

: Biodegradable material,

: Peek,

: Hundred sized Nado metal powder (Feedstork)

: and other special engineering plastic,

Specialized Injection molding machine for Surgery articles.

① Suture Anchors

② Bioabsorbable interference screw

③ Orthopedic Bone fixture plates

Biojet series designed and

specialized the Injection & Molding mechanism so as to save raw material consumption.

Usually, the materials of biodegradable, and Nono Powder of PIM feedstock

is very expensive ones.

Ultimately, to reduce loss rate of material is one of the most important design agenda.

The average loss rate of molding material is lower than 5%.

Biojet series maintain 95% efficience of material consumption.

It's depend on the special mechanism of plasticization together with Functional Mold system.

JD inc will prepare various type of optimum solution for your requirements.

Model : Biojet-2

Injection Volume : 2cc

Hopper Volume : 100cc

Mold Size : 150 x 150 x 150

Model : Biojet-5

Injection Volume : 5cc

Hopper Volume : 250cc

Mold Size : Min. 150 x 150 x 150

Max. 180 x 200 x 170

General Specification

Elec. Power : 380VAC, 3ph

Consumption : Motor 2.2Kw

: Heater 3Kw

Utility : Hydraulic

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Minho Kim

- Address

- 356-10, Hwaseong-si, Gyeonggi-do, Korea

- Product Category

- Medical Consumables,Molds,Other Rubber Products,Plastic & Rubber Machinery Parts,Plastic Product Making Machinery

- Year Established

- 2018

- No. of Total Employees

- 1-50

- Company introduction

-

Business Scope

▷ Mold making

▷ Injection & Extrusion equipments

▷ Automation

▷ R&D

▷ Plant, System Engineering

Business Items

Machineries, Tools, Special Equipments that we make;

① Plastic Injection Molding machines

② LSR Injection molding Machines

③ PIM machineries (with related material handling equipments)

④ CNC Injection molding machines ( Full Automation )

⑤ Special Injection molding machine (LED, Slipring, Relay Connector)

⑥ Extruder,

⑦ Automatic Injecton Molding system

⑧ Specilized/Customized for Ultra Micro & Precision Injection molding sysm.

(LSR, Artificial Eyeball)

Software Service:

Design & Developing manufacturing process of New Materials related

with Injection, extrusion and press technologies.

① New materials of Polymers

② Nano- Powders (Metal, Ceramic),

③ Liquid Silicon Rubber(LSR)

Engineering consulting:

① Part design & Modeling (2D, 3D),

② Process Developing,

③ Plant Engineering.,

Mold Making Service(Specialized)

① Plastic Mold,

② PIM, PICM, PIM2K, PICM2K (Functional Mold for PIM)

③ LSR Mold

Special System (Micro Plant)

① Automatic LED module production system,

② Automatic Relay connector insert molding system,

③ Surgical Anchor (Screw) production system (Biodegradable resign),

④ Artificial Eyeball parts (LSR),

⑤ CNC Injection molding machine.

Special Producing items

① Medical Comsumables : Sutute Anchor (Peek & Biodegradable materials)

② Artificial Organ : Artificial blood vessel (Teflon)

: Artificial Eyeball (LSR)

③ Menstrual Cup (LSR)

④ Industrial Parts

⑤ Cushiion seat of Egg tray(LSR)

- Main Markets

-

South Korea

South Korea

- Factory Information

-

I-SSAN ENGINEERING

- Main Product

Related Products

Surgical / Medical Mask, shoe cover, hair cap

Surgical / Medical Gown

Meline Cross-linked Hyaluronic Acid Dermal Filler

_POWER_COL_TRA_2.jpg)

Made in South Korea High quality K Beauty PLLA(Poly-L-Lactic Acid) POWER COL TRA

iMOOV Vibro Orthotics Real Foot Massage Energy Shoe Inserts Insoles