Drill Rod

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- A.F.W CO., LTD.

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- drill rod, drill rods, friction welding, mining equipment

- Category

- Mining Machinery

Asan Friction Welding Co., Ltd.

- Verified Certificate

-

17

| Product name | Drill Rod | Certification | - |

|---|---|---|---|

| Category | Mining Machinery | Ingredients | - |

| Keyword | drill rod , drill rods , friction welding , mining equipment | Unit Size | 101.6 * 87.4 * 1000.0 mm |

| Brand name | A.F.W CO., LTD. | Unit Weigh | 55 kg |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

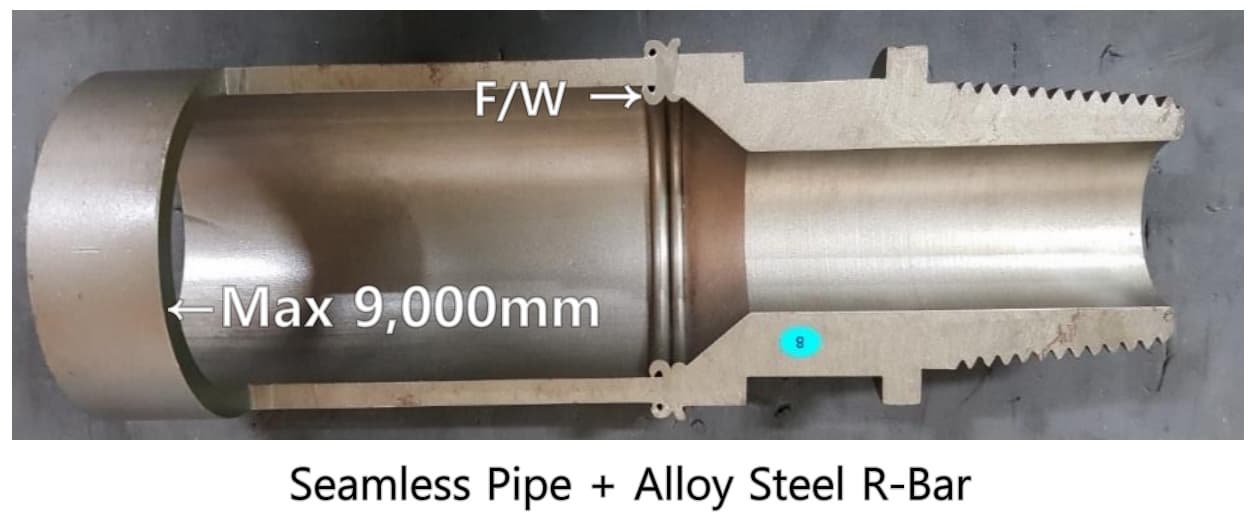

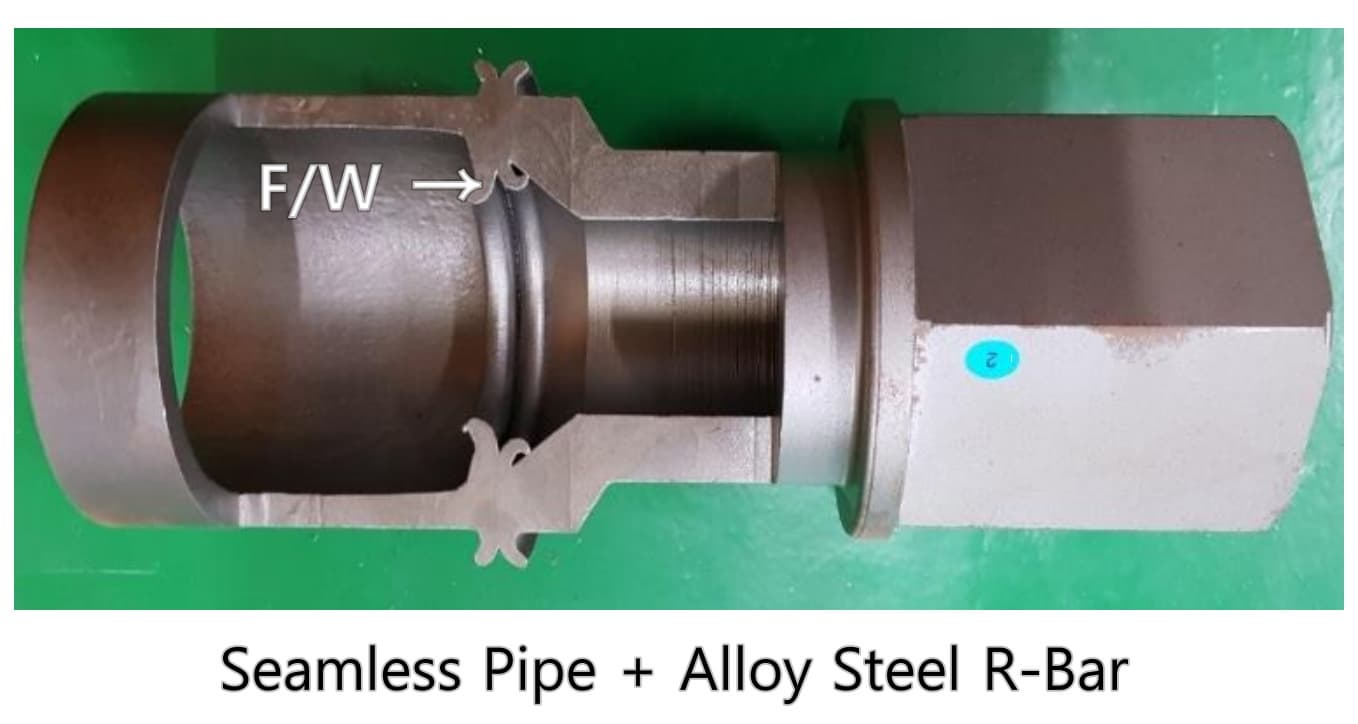

1. Drill Rods with Friction Welding

- It is drilling equipment with Core Barrel and Bit attached at its foremost part and is maintained by the Chuck of the Drill Rig.

- It's main role is conveying the rotation and pressure generated by the drilling machine and making the drilling water reach to the Bit, and also conveying the rapid cooling or slime.

2. The Five Great Advantages of Friction Welding

1)High-Quality bonding strength

Friction heat, vacuum, and instant pressure can bond the surface particles of both base materials thoroughly. The tensile strength of the friction welding joint is higher than that of each base metal. As shown in the photograph, the tensile strength test results in fracture at the base material, not at the joint. When the bending test of the friction welded joint is performed, it is confirmed that the welded portion is bent without being broken.

2)Possible to joint non-ferrous metals and dissimilar materials

3)High welding precision, productivity and environments friendly

Co2 welding, resistance welding, electron beam welding as well as homogeneous materials can be freely bonded to dissimilar metals and nonferrous metals, which are difficult in conventional welding methods. Momentary welding results in fewer heat impacts and little effect on the base material, and the productivity and welding quality are improved by the same working conditions. Environments frendly welding method becase not using welding rod but it rubs base metal and base metal.

4)Wide range of applications

ROD + ROD, ROD + PIPE, PLATE + PIPE, PLATE + ROD can be bonded with different thickness and size, so even parts that could not be welded due to past complex shape can be produced efficiently by using welding.

5)Above all, cheaper manufactureing cost

It is not only cheaper than other welding methods because of high productivity and automated method, Also, manufacturing cost can be reduced by reducing the cost of mold and material cost compared to integral forging or free forging.

1. Drill Rods with Friction Welding

- It is drilling equipment with Core Barrel and Bit attached at its foremost part and is maintained by the Chuck of the Drill Rig.

- It's main role is conveying the rotation and pressure generated by the drilling machine and making the drilling water reach to the Bit, and also conveying the rapid cooling or slime.

2. The Five Great Advantages of Friction Welding

1)High-Quality bonding strength

Friction heat, vacuum, and instant pressure can bond the surface particles of both base materials thoroughly. The tensile strength of the friction welding joint is higher than that of each base metal. As shown in the photograph, the tensile strength test results in fracture at the base material, not at the joint. When the bending test of the friction welded joint is performed, it is confirmed that the welded portion is bent without being broken.

2)Possible to joint non-ferrous metals and dissimilar materials

3)High welding precision, productivity and environments friendly

Co2 welding, resistance welding, electron beam welding as well as homogeneous materials can be freely bonded to dissimilar metals and nonferrous metals, which are difficult in conventional welding methods. Momentary welding results in fewer heat impacts and little effect on the base material, and the productivity and welding quality are improved by the same working conditions. Environments frendly welding method becase not using welding rod but it rubs base metal and base metal.

4)Wide range of applications

ROD + ROD, ROD + PIPE, PLATE + PIPE, PLATE + ROD can be bonded with different thickness and size, so even parts that could not be welded due to past complex shape can be produced efficiently by using welding.

5)Above all, cheaper manufactureing cost

It is not only cheaper than other welding methods because of high productivity and automated method, Also, manufacturing cost can be reduced by reducing the cost of mold and material cost compared to integral forging or free forging.

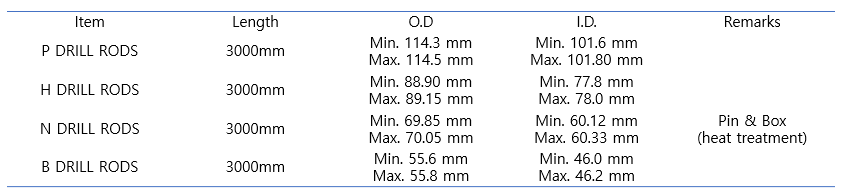

In addition to the below specifications, We produce various size of drill rods

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- JIN JEUNG AH

- Address

- 51, Gongdan-ro 1-gil, Waegwan-eup, Chilgok-gun, Gyeongsangbuk-do, Korea

- Product Category

- Other Power Tools

- Year Established

- 1998

- No. of Total Employees

- 101-500

- Company introduction

-

- Main Markets

-

China

China

Hong Kong(China)

Hong Kong(China)

Hungary

Hungary

Saudi Arabia

Saudi Arabia

Singapore

Singapore

Thailand

Thailand

- Main Product

Related Products

_2.jpg)

Turbowin Turbo Blower (WL Series)

_2.png)

Turbowin Turbo Compressor (WH Series)

Rock Drill Spare Parts

Tubing Pup Joint 2-3/8“ 4.7LB/FT EUE 8RD

Cummins engine parts

South Korea

South Korea