Slag Pot/Slag Ladle in the Steel Plant

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- CHAENG

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery Parts

Xinxiang Great Wall Machinery Co., Ltd.

- Verified Certificate

-

6

| Product name | Slag Pot/Slag Ladle in the Steel Plant | Certification | - |

|---|---|---|---|

| Category | Other Machinery Parts | Ingredients | - |

| Keyword | steel casting machining , holding steel slag , slag pot carrier , slag pot manufacture | Unit Size | - |

| Brand name | CHAENG | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

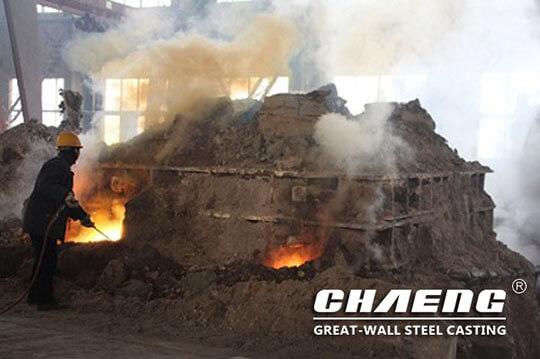

Slag pot (slag ladle) is important device in steel making It is a load-bearing device to collect molten or solid slag generated during metallurgical or chemical processes CHAENG (Great Wall Steel Casting Co , Ltd) makes continuous technical innovation in casting process, and CHAENG slag pot has more advantages such as short cast period, long service life and strong resistance to deformation We can manufacture slag pots according to usres drawings.

Slag pot (slag ladle) is important device in steel making It is a load-bearing device to collect molten or solid slag generated during metallurgical or chemical processes CHAENG (Great Wall Steel Casting Co , Ltd) makes continuous technical innovation in casting process, and CHAENG slag pot has more advantages such as short cast period, long service life and strong resistance to deformation We can manufacture slag pots according to usres drawings

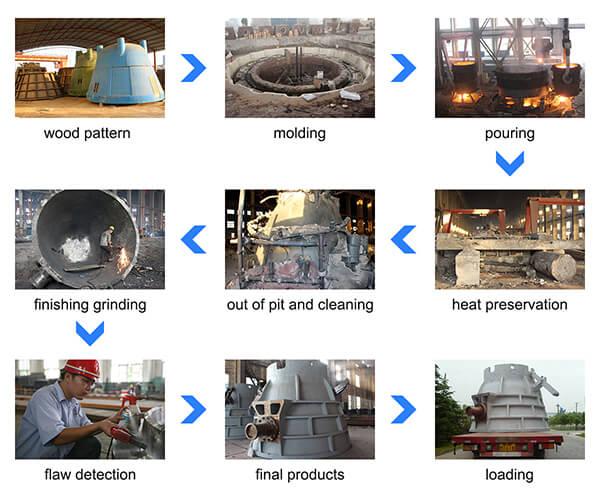

Slag pot manufacturing process:

In the development of the past ten years, CHAENG has been insisting on continuous innovation and learning. In-depth optimization of the material and structure of the slag pot, and learning of the international advanced casting process. In addition, the company's professional R & D design team and high-precision production equipment can fully guarantee the quality of the slag pot.

Advantages of slag irrigation:

First,each slag pot is digitally simulated by CAE software before casting. The process analysis and quality prediction of the product forming process are carried out by digital simulation technology, and the process optimization of slag pot casting is completed. Second,For the problem that the two materials of slag can trunnion alloy steel and pot carbon steel are difficult to weld, CHAENG has customized a complete process to strictly control the welding problems in the production process of slag pots;

360 ° non-destructive testing of the inner wall of the slag pot, the trunnion and the tilting mechanism with advanced flaw detection equipment to ensure the internal and external quality of the slag pot. The slag pot material produced by CHAENG is mature, the manufacturing process is stable, the deformation resistance is strong, and the service life can be as long as 6000 times.

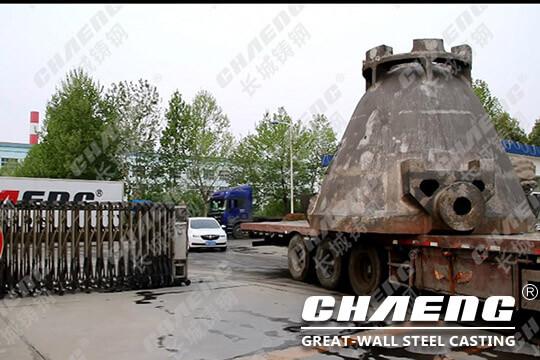

On July 18, 2008, CHAENG signed the first contract of slag pot, under the situation of financial crisis and shrinking market, on the same year on December 12 we signed 13 pcs of slag pot with South Korea's posco, since 2008 we have signed the contract of more than 50 types of slag pot, and produce 287 pieces of casting process, "they" are exported to countries around the world: the United States Mittal, Germany, Italy, India's TATA steel company, Japan Chiba, Canada, Taiwan, South Korea, the United States, Mexico, Canada and other overseas countries.

Place of Origin:China

Supply Type:OEM service

Condition:New

Model Number:based on drawing sheet

Brand Name:CHAENG

authentication certificate:ISO9001:2015 CE

Material:Steel casting

Weight:1-150 tons

Type:Casting slag irrigation

size:According to the drawings

Supply capacity:30000Ton/Tons per year

Period for delivery:60workday

Packaging:Standard packaging or packaging as required

procedure:Sand casting

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Mr.Wang

- Address

- South of Jiantou Village, Mengzhuang Town Xinxiang 453621 CHINA

- Product Category

- Other Machinery Parts

- Year Established

- 1958

- Company introduction

-

After 60 years of development, the company relies on its strong casting, processing and assembly capabilities. We can provide customers with one-stop solutions for all kinds of high-end equipment supporting steel castings, including optimization design, analysis and simulation, product casting and parts of various steel castings such as single-ton 150-ton large carbon steel, manganese steel and high-alloy steel. Six services for processing, component assembly and finished product delivery. It is a high-quality supporting service provider of world-renowned metallurgical and building materials equipment companies such as Mittal, Tata, Pohang, Smith, and Loesche. The products are exported to the United States, Germany, France, Italy, India, Indonesia, South Korea, Turkey, etc. Countries and regions have high market visibility.

- Main Product

Related Products

Electric ULV Sprayer ATOMER 2

Diamond Tools: Diamond Blade, Diamond Polishing Pads, Diamond Grinding Wheel, Diamond Wire Saw

Knitted wire mesh Gaskets Seals

JS-2EJ4

All in one POS SYSTEM

China

China