vitrified bonded diamond grinding wheel

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- D/A,D/P,L/C,MoneyGram,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- diamond grinding wheel, grinding wheel, vitrified bonded, vitrified bonded diamond grinding wheel

- Category

- Abrasive Tools

More super hard product company

- Verified Certificate

-

7

| Product name | vitrified bonded diamond grinding wheel | Certification | - |

|---|---|---|---|

| Category | Abrasive Tools | Ingredients | - |

| Keyword | diamond grinding wheel , grinding wheel , vitrified bonded , vitrified bonded diamond grinding wheel | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

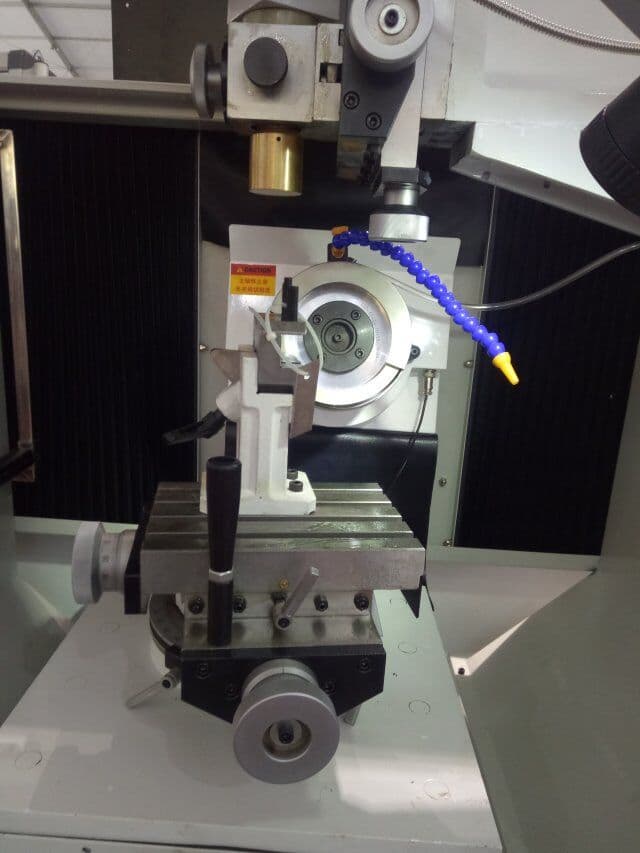

Vitrified bonded diamond cup grinding wheel

Advantages and disadvantages of Vitrified binding agents

Vitrified bonded grinding wheel has high temperature resistance.High processing efficiency, good rigidity, in the grinding process to maintain the shape of cutting tools, finished product size accuracy can be guaranteed and other advantages.

Using Vitrified bonded diamond grinding wheel to grind PCD tools can improve the grinding efficiency to the greatest extent.

And grinding ratio is small, wear-resisting degree is high, service life is long, processing cost is low, have extensive practical significance and promotion value.

The grinding surface quality of Vitrified bonded diamond grinding wheel is good, which is close to the grinding quality of metal bonded grinding wheel, and its grinding efficiency is very high, about 4 times of that of metal bonded grinding wheel, which has been proved by experiments.

However, due to the poor thermal stability and large inertia of diamond, it is difficult to prepare the Vitrified bonded diamond grinding wheel, and the performance of the grinding wheel batch is not stable. Therefore, the extensive application of the Vitrified bonded diamond grinding wheel is limited.

1. Use of Vitrified bonded grinding wheel

The most widely used vitrified bonded diamond grinding wheel is mainly used for PCD, CVD, PCBN, carbide, vitrified cutting tools and other cutting tools such as milling cutter, drill bit, reamer, etc.

2. Vitrified binding Material

Compared with common corundum and silicon carbide grinding tools, vitrified bond has strong grinding force, lower temperature and less abrasion. Vitrified bond grinding wheel can adapt to the effect of various coolant.

When you use the vitrified bond grinding wheel to grinding, the shape of the grinding tool is good and the precision of the workpiece is high.

There are many holes in the grinding tool, which is conducive to chip removal, chip storage and heat dissipation during grinding. The self-sharpening of the grinding tool is better, and the dressing interval is longer, so it is easier to finish.

Therefore, the use of vitrified bonded diamond abrasive tools is increasing in some developed countries.

vitrified bonded diamond grinding wheel has the following advantages

1) high grinding efficiency;

2) high abrasion resistance: the abrasion resistance of the grinding wheel is high and the abrasive grain consumption is low, especially when the workpiece is hard and brittle.

3) low grinding force and low grinding temperature;

4) high precision, good surface quality and good shape retention of the grinding workpiece.

Therefore, the vitrified bonded diamond grinding wheel has more and more advantages in the grinding of some special materials, such as vitrifieds and has a good prospect in the development of diamond grinding wheel.

As a high performance grinding wheel with high speed, high efficiency, high precision, low grinding cost and low environmental pollution, it has been widely used and become a hot spot in the research and development of grinding tools around the world.

The content of the binder has three effects on the diamond grinding wheel

(1) effect on the hardness of diamond grinding wheel.

The hardness of grinding wheel refers to the difficulty degree of the superhard abrasive material falling off the grinding wheel. The harder the abrasive particles fall off, the higher the hardness of the grinding wheel is.

Generally speaking, the more the combined dose, the stronger the control on the abrasive, the harder the abrasive particles fall off, and the higher the hardness of the grinding wheel.

During grinding, the blade of the grinding wheel is not good and it is easy for the grinding wheel to remain still. The life of the diamond grinding wheel will be increased. However, the surface of the composite disc is easy to crack.

(2) the effect on the binding strength of the binder content and diamond abrasive.

The hardness of the composite sheet is very high. During the external grinding process, the diamond on the surface of grinding wheel receives great grinding force and impact force.

If the vitrified bond dose is too small, the vitrified bond does not keep enough on the diamond, which results in that some diamonds do not play a full grinding role and begin to fall off, resulting in shorter life of the vitrified diamond grinding wheel.

However, when there are too many binders, the hardness of the grinding wheel is too high, and the cutting edge is not enough, it is easy to cause the composite sheet to collapse, resulting in the increase of reject rate.

(3) influence on the structure of grinding wheel.

As the size of the binding agent used is finer than that of diamond, and the binding agent will be densified in the process of burning.

With the increase in the content of binders in the vitrified diamond grinding wheel, the more compact the structure of the grinding wheel, the more clogging the grinding wheel is likely to occur and the grinding wheel will not move. It is often necessary to use the ordinary grinding wheel to cut the super-hard material grinding wheel, remove the redundant binders, make the new diamond cutting edge participate in the next grinding, and reduce the working efficiency of the grinding wheel.

Vitrified bonded diamond cup grinding wheel

Advantages and disadvantages of Vitrified binding agents

Vitrified bonded grinding wheel has high temperature resistance.High processing efficiency, good rigidity, in the grinding process to maintain the shape of cutting tools, finished product size accuracy can be guaranteed and other advantages.

Using Vitrified bonded diamond grinding wheel to grind PCD tools can improve the grinding efficiency to the greatest extent.

And grinding ratio is small, wear-resisting degree is high, service life is long, processing cost is low, have extensive practical significance and promotion value.

The grinding surface quality of Vitrified bonded diamond grinding wheel is good, which is close to the grinding quality of metal bonded grinding wheel, and its grinding efficiency is very high, about 4 times of that of metal bonded grinding wheel, which has been proved by experiments.

However, due to the poor thermal stability and large inertia of diamond, it is difficult to prepare the Vitrified bonded diamond grinding wheel, and the performance of the grinding wheel batch is not stable. Therefore, the extensive application of the Vitrified bonded diamond grinding wheel is limited.

1. Use of Vitrified bonded grinding wheel

The most widely used vitrified bonded diamond grinding wheel is mainly used for PCD, CVD, PCBN, carbide, vitrified cutting tools and other cutting tools such as milling cutter, drill bit, reamer, etc.

2. Vitrified binding Material

Compared with common corundum and silicon carbide grinding tools, vitrified bond has strong grinding force, lower temperature and less abrasion. Vitrified bond grinding wheel can adapt to the effect of various coolant.

When you use the vitrified bond grinding wheel to grinding, the shape of the grinding tool is good and the precision of the workpiece is high.

There are many holes in the grinding tool, which is conducive to chip removal, chip storage and heat dissipation during grinding. The self-sharpening of the grinding tool is better, and the dressing interval is longer, so it is easier to finish.

Therefore, the use of vitrified bonded diamond abrasive tools is increasing in some developed countries.

vitrified bonded diamond grinding wheel has the following advantages

1) high grinding efficiency;

2) high abrasion resistance: the abrasion resistance of the grinding wheel is high and the abrasive grain consumption is low, especially when the workpiece is hard and brittle.

3) low grinding force and low grinding temperature;

4) high precision, good surface quality and good shape retention of the grinding workpiece.

Therefore, the vitrified bonded diamond grinding wheel has more and more advantages in the grinding of some special materials, such as vitrifieds and has a good prospect in the development of diamond grinding wheel.

As a high performance grinding wheel with high speed, high efficiency, high precision, low grinding cost and low environmental pollution, it has been widely used and become a hot spot in the research and development of grinding tools around the world.

The content of the binder has three effects on the diamond grinding wheel

(1) effect on the hardness of diamond grinding wheel.

The hardness of grinding wheel refers to the difficulty degree of the superhard abrasive material falling off the grinding wheel. The harder the abrasive particles fall off, the higher the hardness of the grinding wheel is.

Generally speaking, the more the combined dose, the stronger the control on the abrasive, the harder the abrasive particles fall off, and the higher the hardness of the grinding wheel.

During grinding, the blade of the grinding wheel is not good and it is easy for the grinding wheel to remain still. The life of the diamond grinding wheel will be increased. However, the surface of the composite disc is easy to crack.

(2) the effect on the binding strength of the binder content and diamond abrasive.

The hardness of the composite sheet is very high. During the external grinding process, the diamond on the surface of grinding wheel receives great grinding force and impact force.

If the vitrified bond dose is too small, the vitrified bond does not keep enough on the diamond, which results in that some diamonds do not play a full grinding role and begin to fall off, resulting in shorter life of the vitrified diamond grinding wheel.

However, when there are too many binders, the hardness of the grinding wheel is too high, and the cutting edge is not enough, it is easy to cause the composite sheet to collapse, resulting in the increase of reject rate.

(3) influence on the structure of grinding wheel.

As the size of the binding agent used is finer than that of diamond, and the binding agent will be densified in the process of burning.

With the increase in the content of binders in the vitrified diamond grinding wheel, the more compact the structure of the grinding wheel, the more clogging the grinding wheel is likely to occur and the grinding wheel will not move. It is often necessary to use the ordinary grinding wheel to cut the super-hard material grinding wheel, remove the redundant binders, make the new diamond cutting edge participate in the next grinding, and reduce the working efficiency of the grinding wheel.

Vitrified bonded diamond cup grinding wheel

Advantages and disadvantages of Vitrified binding agents

Vitrified bonded grinding wheel has high temperature resistance.High processing efficiency, good rigidity, in the grinding process to maintain the shape of cutting tools, finished product size accuracy can be guaranteed and other advantages.

Using Vitrified bonded diamond grinding wheel to grind PCD tools can improve the grinding efficiency to the greatest extent.

And grinding ratio is small, wear-resisting degree is high, service life is long, processing cost is low, have extensive practical significance and promotion value.

The grinding surface quality of Vitrified bonded diamond grinding wheel is good, which is close to the grinding quality of metal bonded grinding wheel, and its grinding efficiency is very high, about 4 times of that of metal bonded grinding wheel, which has been proved by experiments.

However, due to the poor thermal stability and large inertia of diamond, it is difficult to prepare the Vitrified bonded diamond grinding wheel, and the performance of the grinding wheel batch is not stable. Therefore, the extensive application of the Vitrified bonded diamond grinding wheel is limited.

1. Use of Vitrified bonded grinding wheel

The most widely used vitrified bonded diamond grinding wheel is mainly used for PCD, CVD, PCBN, carbide, vitrified cutting tools and other cutting tools such as milling cutter, drill bit, reamer, etc.

2. Vitrified binding Material

Compared with common corundum and silicon carbide grinding tools, vitrified bond has strong grinding force, lower temperature and less abrasion. Vitrified bond grinding wheel can adapt to the effect of various coolant.

When you use the vitrified bond grinding wheel to grinding, the shape of the grinding tool is good and the precision of the workpiece is high.

There are many holes in the grinding tool, which is conducive to chip removal, chip storage and heat dissipation during grinding. The self-sharpening of the grinding tool is better, and the dressing interval is longer, so it is easier to finish.

Therefore, the use of vitrified bonded diamond abrasive tools is increasing in some developed countries.

vitrified bonded diamond grinding wheel has the following advantages

1) high grinding efficiency;

2) high abrasion resistance: the abrasion resistance of the grinding wheel is high and the abrasive grain consumption is low, especially when the workpiece is hard and brittle.

3) low grinding force and low grinding temperature;

4) high precision, good surface quality and good shape retention of the grinding workpiece.

Therefore, the vitrified bonded diamond grinding wheel has more and more advantages in the grinding of some special materials, such as vitrifieds and has a good prospect in the development of diamond grinding wheel.

As a high performance grinding wheel with high speed, high efficiency, high precision, low grinding cost and low environmental pollution, it has been widely used and become a hot spot in the research and development of grinding tools around the world.

The content of the binder has three effects on the diamond grinding wheel

(1) effect on the hardness of diamond grinding wheel.

The hardness of grinding wheel refers to the difficulty degree of the superhard abrasive material falling off the grinding wheel. The harder the abrasive particles fall off, the higher the hardness of the grinding wheel is.

Generally speaking, the more the combined dose, the stronger the control on the abrasive, the harder the abrasive particles fall off, and the higher the hardness of the grinding wheel.

During grinding, the blade of the grinding wheel is not good and it is easy for the grinding wheel to remain still. The life of the diamond grinding wheel will be increased. However, the surface of the composite disc is easy to crack.

(2) the effect on the binding strength of the binder content and diamond abrasive.

The hardness of the composite sheet is very high. During the external grinding process, the diamond on the surface of grinding wheel receives great grinding force and impact force.

If the vitrified bond dose is too small, the vitrified bond does not keep enough on the diamond, which results in that some diamonds do not play a full grinding role and begin to fall off, resulting in shorter life of the vitrified diamond grinding wheel.

However, when there are too many binders, the hardness of the grinding wheel is too high, and the cutting edge is not enough, it is easy to cause the composite sheet to collapse, resulting in the increase of reject rate.

(3) influence on the structure of grinding wheel.

As the size of the binding agent used is finer than that of diamond, and the binding agent will be densified in the process of burning.

With the increase in the content of binders in the vitrified diamond grinding wheel, the more compact the structure of the grinding wheel, the more clogging the grinding wheel is likely to occur and the grinding wheel will not move. It is often necessary to use the ordinary grinding wheel to cut the super-hard material grinding wheel, remove the redundant binders, make the new diamond cutting edge participate in the next grinding, and reduce the working efficiency of the grinding wheel.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,MoneyGram,T/T,Western Union | Shipping time | Negotiable |

- President

- Joe

- Address

- No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, Henan,450001 China

- Product Category

- Abrasive Tools,Abrasives

- Year Established

- 2010

- No. of Total Employees

- 51-100

- Company introduction

-

More Super Hard Products Co., Ltd Is Specialized In Manufacturing And Marketing Of Synthetic Diamond Tools, Cubic Boron Nitride(CBN) Tools, Which Is Widely Used In Petroleum And Geology Industry, Auto Aviation Processing Industry, Electric Processing Industry, Natural Diamond And Jewelry Processing Industry And Other Ultra- Precision Industry .

The Company Production And Sales Of Products Covered Vitrified Bond Tools, Resin Bond Tools, Metal Bond Tools, Electroplated Diamond/CBN Tools, Vaccum Brazed Products, CVD Diamond Tools, Polycrystalline Diamond (PCD) Tools, Cubic Boron Nitride (CBN) Tools.Our Objective Is To Meet All The Customers’ Needs And Help Every Customer Achieve Maximum Benefits. More Brings In Revenue For You, You Win, We Win!

More Super Hard Supplies The Wheels For Several Application Mainly:

* Carbide Round Tools On CNC Machines : Flute Grinding, Gash Grinding, End Facing, Clearance Angle And Cylindrical Grinding .

* Insert Grinding For Machines Such As: AGATHON, WENDT, HAAS, WAIDA And EWAG.

* Woodworking Saw Blade And Tools .

* HSS Tools .

* Cutting Wheels.

- Main Product

China

China