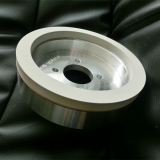

cbn grinding wheel for crankshaft grinding

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- More super hard

- Payment Terms

- D/A,D/P,L/C,MoneyGram,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- cbn, cbn grinding wheel, crankshaft, crankshaft machining

- Category

- Abrasive Tools

More super hard product company

- Verified Certificate

-

7

| Product name | cbn grinding wheel for crankshaft grinding | Certification | - |

|---|---|---|---|

| Category | Abrasive Tools | Ingredients | - |

| Keyword | cbn , cbn grinding wheel , crankshaft , crankshaft machining | Unit Size | - |

| Brand name | More super hard | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

CBN Wheel For Camshaft Grinding

Use CBN wheel non-circular grinding CAM, camshaft, CAM piece and pump ring

It is obvious from the example of camshaft that non-circular parts must be processed in the manufacturing process.

Unlike circular grinding, which is perfectly circular, non-circular grinding must be made into a defined non-circular shape and finished by grinding process.

Non-circular shaft components include camshaft, CAM disk and pump shaft.

Different manufacturing tasks also have different requirements for machine tool configuration.

But even for a narrow range of processing tasks, such as the grinding of car camshafts, a single machine tool configuration cannot meet the market's demands.

Therefore, modular machine tools and technological concepts are essential for non-circular machining.

It may also be necessary to use multiple grinding spindles for rough and finishing or complete machining, such as a double slide grinder for simultaneous or synchronous support grinding.

CBN grinding technology for non-circular machining

CBN is the most advanced technology in the field of non-circular grinding.

In the future, productivity will be increased by further increasing cutting speed.

For parts, such as compound camshaft, which have lower grinding allowance and higher instability, a grinding system with significantly reduced grinding force must be developed.

The increasing and changing market demands will also be the driving force for innovation in the field of non-circular grinding technology in the future.

In order to meet the different requirements of grinding machine and machining process, emark provides a variety of modular systems consisting of process modules and machine tools, which you can adjust flexibly according to the corresponding production conditions (see below).

The sample application

Camshaft machining is a typical example of non-circular grinding.

For example, in a completed turnkey project, four double cams are ground by manual feeding.

The challenge of this operation to the grinding technique is: up to 3 mm margin in rough machining, and only use a grinding tool for finishing.

These seemingly contradictory requirements can be met by a ceramic CBN grinding wheel.

Another example is the complete processing of the truck camshaft: twelve distribution cams, six pump cams, seven journal supports, thrust bearings and tapered shaft ends and shoulder are processed in a single clamp.

As the inherent stress is often released during grinding of hardened bearings and CAM grinding affects the diameter jump of the journal support, it is not possible to process the bearings in a single process according to the drawing.

To achieve the required quality, processing in a single clip is usually the best approach.

vitrified bond CBN grinding wheels for crankshaft and camshaft

vitrified bond CBN grinding wheel is suitable for high-efficient heavy grinding of crankshaft and camshaft of automobile parts. The wheel speed is 80m/s--120m/s. Designed to be used on crank and cam CNC grinders like Toyoda, Schaudt, Landis, junker.

Workpieces:

Cast iron series( such as cold cast iron,nodular cast iron,grey cast iron,lly Castiron) and steel series (such as 20Cr、GCr15、CF53、#45、#55、80B).

Application Of Vitrified CBN Grinding Wheel For Camshaft:

ceramic bond CBN wheel used in processing iron, steel and ferrous metal materials, cancoarse, prcision, fine Finishing,

for high fficient and heavy grinding ofcrankshaft and camshaft of Automobile,Trackor,Transport.

The Specifications Of Vitrified CBN Grinding Wheel For Camshaft:

type | D | T | H | X |

1A1 | 500 | 20,24 | 203,304.8,305 | 5,8,10 |

1A1 | 600 | 20,23,35 | 132,304.8,305 | 5,10 |

1A1 | 650 | 43.5,47.5,50.5 | 132,152.4,304.8 | 6,11 |

1A1 | 700 | 50,56 | 94,159 | 10,12 |

Features:high fficiencny and precision without burning and annaling,easy to dress an durability.

Machines:Junker,Toyoda scuaudt, EMAG,LANDIS.

Automobile engine crankshaft grinding application project and technical parameters

Automotive engine crankshaft grinding application case | |

CNC grinding machine name | German Junker JUCRANK6L |

Grinding wheel | MORE’S Grinding crankshaft CBN grinding wheel |

Size | D700x56x159.94x12x34 02B151-350-H03-54V2A |

Material of Crankshaft workpiece | 42CrMoA |

Grinding cooling method | Oil cold |

Workpiece processing beat | 20min |

Work surface roughness | Ra0.5 |

Workpiece grinding amount | Face 0.1mm, Outer circle 0.2mm |

The following is a machining case for crankshaft grinding

Crankshaft grinding machine related technical parameters | |

Processing part | Air compressor compressor crankshaft thrust surface |

Grinding wheel speed | 2345rpm |

CBN grinding wheel dressing method | Diamond dressing tools |

Grinding wheel cooling method | Water cooled |

Air conditioner compressor crankshaft related parameters | |

Name of the artifact | crankshaft |

Woekpiece material | FCE200 |

Number of thrust faces | 1 |

Workpiece industry | Air conditioning compressor industry |

Crankshaft grinding ceramic wheel parameters | |

abrasive | CBN |

bond | vitirfied |

Grit | custom |

Vitrified cbn grinding wheel size | 4BI 450x26x153x8x8x45° |

body | Aluminium alloy matrix |

Workpiece processing parameters | |

Workpiece processing beat | 24s |

Surface roughness value workpiece before grinding | RZ6.0 |

Surface roughness value after grinding | RZ1.5 |

vitrified CBN grinding wheel dressing cycle | 1100pcs |

Total amount of single side grinding of workpiece | 0.19mm |

Coarse grinding amount | 0.14mm |

Width of workpiece machining surface | 3.70mm |

The above is the relevant case and information of the crankshaft grinding CBN ceramic grinding wheel processing crankshaft from More super hard comapny.

This specification model can be customized high precision grinding crankshaft CBN grinding wheel, also can be stator grinding camshaft CBN grinding wheel.

vitrified bond CBN grinding wheels for crankshaft and camshaft

vitrified bond CBN grinding wheel is suitable for high-efficient heavy grinding of crankshaft and camshaft of automobile parts. The wheel speed is 80m/s--120m/s. Designed to be used on crank and cam CNC grinders like Toyoda, Schaudt, Landis, junker.

Workpieces:

Cast iron series( such as cold cast iron,nodular cast iron,grey cast iron,lly Castiron) and steel series (such as 20Cr、GCr15、CF53、#45、#55、80B).

Application Of Vitrified CBN Grinding Wheel For Camshaft:

ceramic bond CBN wheel used in processing iron, steel and ferrous metal materials, cancoarse, prcision, fine Finishing,

for high fficient and heavy grinding ofcrankshaft and camshaft of Automobile,Trackor,Transport.

The Specifications Of Vitrified CBN Grinding Wheel For Camshaft:

type | D | T | H | X |

1A1 | 500 | 20,24 | 203,304.8,305 | 5,8,10 |

1A1 | 600 | 20,23,35 | 132,304.8,305 | 5,10 |

1A1 | 650 | 43.5,47.5,50.5 | 132,152.4,304.8 | 6,11 |

1A1 | 700 | 50,56 | 94,159 | 10,12 |

Features:high fficiencny and precision without burning and annaling,easy to dress an durability.

Machines:Junker,Toyoda scuaudt, EMAG,LANDIS.

Automobile engine crankshaft grinding application project and technical parameters

Automotive engine crankshaft grinding application case | |

CNC grinding machine name | German Junker JUCRANK6L |

Grinding wheel | MORE’S Grinding crankshaft CBN grinding wheel |

Size | D700x56x159.94x12x34 02B151-350-H03-54V2A |

Material of Crankshaft workpiece | 42CrMoA |

Grinding cooling method | Oil cold |

Workpiece processing beat | 20min |

Work surface roughness | Ra0.5 |

Workpiece grinding amount | Face 0.1mm, Outer circle 0.2mm |

The following is a machining case for crankshaft grinding

Crankshaft grinding machine related technical parameters | |

Processing part | Air compressor compressor crankshaft thrust surface |

Grinding wheel speed | 2345rpm |

CBN grinding wheel dressing method | Diamond dressing tools |

Grinding wheel cooling method | Water cooled |

Air conditioner compressor crankshaft related parameters | |

Name of the artifact | crankshaft |

Woekpiece material | FCE200 |

Number of thrust faces | 1 |

Workpiece industry | Air conditioning compressor industry |

Crankshaft grinding ceramic wheel parameters | |

abrasive | CBN |

bond | vitirfied |

Grit | custom |

Vitrified cbn grinding wheel size | 4BI 450x26x153x8x8x45° |

body | Aluminium alloy matrix |

Workpiece processing parameters | |

Workpiece processing beat | 24s |

Surface roughness value workpiece before grinding | RZ6.0 |

Surface roughness value after grinding | RZ1.5 |

vitrified CBN grinding wheel dressing cycle | 1100pcs |

Total amount of single side grinding of workpiece | 0.19mm |

Coarse grinding amount | 0.14mm |

Width of workpiece machining surface | 3.70mm |

The above is the relevant case and information of the crankshaft grinding CBN ceramic grinding wheel processing crankshaft from More super hard comapny.

This specification model can be customized high precision grinding crankshaft CBN grinding wheel, also can be stator grinding camshaft CBN grinding wheel.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,MoneyGram,T/T,Western Union | Shipping time | Negotiable |

- President

- Joe

- Address

- No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, Henan,450001 China

- Product Category

- Abrasive Tools,Abrasives

- Year Established

- 2010

- No. of Total Employees

- 51-100

- Company introduction

-

More Super Hard Products Co., Ltd Is Specialized In Manufacturing And Marketing Of Synthetic Diamond Tools, Cubic Boron Nitride(CBN) Tools, Which Is Widely Used In Petroleum And Geology Industry, Auto Aviation Processing Industry, Electric Processing Industry, Natural Diamond And Jewelry Processing Industry And Other Ultra- Precision Industry .

The Company Production And Sales Of Products Covered Vitrified Bond Tools, Resin Bond Tools, Metal Bond Tools, Electroplated Diamond/CBN Tools, Vaccum Brazed Products, CVD Diamond Tools, Polycrystalline Diamond (PCD) Tools, Cubic Boron Nitride (CBN) Tools.Our Objective Is To Meet All The Customers’ Needs And Help Every Customer Achieve Maximum Benefits. More Brings In Revenue For You, You Win, We Win!

More Super Hard Supplies The Wheels For Several Application Mainly:

* Carbide Round Tools On CNC Machines : Flute Grinding, Gash Grinding, End Facing, Clearance Angle And Cylindrical Grinding .

* Insert Grinding For Machines Such As: AGATHON, WENDT, HAAS, WAIDA And EWAG.

* Woodworking Saw Blade And Tools .

* HSS Tools .

* Cutting Wheels.

- Main Product

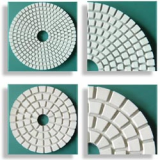

Related Products

Diamond Wheels for Walter Grinding Machine

Engineered Stone Polishing Pad

11V9 Resin Bond Flaring Cup Wheel

Abrasive wheel

Diamond Hand PAD 60 ~ 3000 - Abrasive Tools, Grinding Tool

China

China