Silicon Carbide

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Anyang Huatuo Metallurgy Co.,LTD

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Silica

Anyang Huatuo Metallurgy Co.,Ltd.

- Verified Certificate

-

7

| Product name | Silicon Carbide | Certification | - |

|---|---|---|---|

| Category | Silica | Ingredients | - |

| Keyword | silicon carbide , silicon carbide black , silicon carbide powder , silicon carbide deoxidizer | Unit Size | 10.0 * 100.0 * 0.0 mm |

| Brand name | Anyang Huatuo Metallurgy Co.,LTD | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Silicon Carbide

- Name:Silicon Carbide

- Model:SiC88, SiC90, SiC97

- Size:0-5mm,0-10mm, 1-10mm

- Shape:Powder, Grit, Lumps

- Usage:Refractories, Abrasives, Metallurgy

Silicon carbide is a man-made material manufactured through heating silica sand and carbon to high temperatures in the Acheson furnace technique. Silicon carbide is an extremely hard material (Mohs hardness 9.25), is chemically inert and does not melt. Silicon Carbide has a high thermal conductivity, a low coefficient of thermal expansion, is thermal shock and abrasion resistant and has strength at high temperatures. Silicon carbide's varied properties make it an effective material in many different applications.

Silicon carbide contains two common basic varieties: black silicon carbide and green silicon carbide. Black silicon carbide contains sic about 95%, so the toughness is higher than green silicon carbide. It is widely used for processing low tensile strength material like glass, ceramics, stone, refractory material, cast iron and nonferrous metal etc. Green silicon carbide contains sic about 97% above with good self-sharpening, so it is used for processing hard alloy, titanium alloy and optical glass as well as cylinder jacket and fine grinding cutting tools.

Silicon carbide has good hardness only second to the hardest diamond, hardness is 9.5. Due to good thermal conductivity, silicon carbide is a kind of semiconductor and can oxidation resistance in high temperature. Silicon carbide has wide applications because of stable chemical performance, high thermal conductivity, small thermal expansion coefficient, good wear-resisting performance. Low grade silicon carbide about 85% is an excellent deoxidizer, which can speed up steel making and facilitate the control of chemical composition to improve the steel quality. Therefore, the market price of silicon carbide is still stable.

Applications of Silicon Carbide:

★ Metallurgical deoxidizer.

★ High temperature resistant materials.

★ As abrasive, abrasive tools can be used to such as grinding wheels, whetstones,

Specifications of Silicon Carbide

| Model | Chemical Composition % | ||

|---|---|---|---|

| SiC | Free Carbon | Fe2O3 | |

| SiC 98.5 | 98.5 min | 0.2 max | 0.60 max |

| SiC 97 | 97.0 min | 0.3 max | 1.20 max |

| SiC 95 | 95.0 min | 0.6 max | 1.20 max |

| SiC 90 | 90.0 min | 1.0 max | 1.20 max |

| SiC 88 | 88.0 min | 4.0 max | 1.5 max |

| Model No. | SiC | Al2O3 | Fe2O3 |

| SiC Briquette 70 | 70.0 min | 5.0 max | 3.0 max |

| SiC Briquette 65 | 65.0 min | 5.0 max | 3.0 max |

- Name:Silicon Carbide

- Model:SiC88, SiC90, SiC97

- Size:0-5mm,0-10mm, 1-10mm

- Shape:Powder, Grit, Lumps

- Usage:Refractories, Abrasives, Metallurgy

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Mr. Wang

- Address

- Industrial Park of Dong zhang wu, Qugou Town, Anyang City, Henan Province, China. 455133 CHINA

- Product Category

- Other Minerals & Metallurgy Products

- Year Established

- 1995

- No. of Total Employees

- 1-50

- Company introduction

-

Established in 1995, Anyang Huatuo Metallurgy Co., Ltd. is specialized in ferro silicon export. As a professional and reliable ferro silicon and slag supplier, we have built cooperation with over 20 countries and regions, including U.S.A. Chile, Argentina, Turkey, Mexico, Korea, Japan, etc. So Huatuo metallurgy has a great share in global market. Our ferroalloy contains ferrosilicon, ferrosilicon briquette, nodulizer, calcium silicon, cored wire, silicon carbide, SiAlBaCa alloy etc. The ferroalloy is mainly used in steel making deoxidizer, casting materials and refractory.

Our factory locates in Qugou Town, Anyang city, Henan province, China with a total area of about 40,000 square meters. With strong technical strength and advanced equipment, we have high quality ferroalloy in ferro silicon, nodulizer, silicon briquette, silicon slag etc. over 10 years. Competitive prices, great service, high quality and time delivery is our business concept. We are based on the equality and mutual benefits to cooperate with partners all over the world.

Our History

From 1995 to 2018The quality is the key principle, while service is the guarantee of stable development and trade business is the customers trust and support. We have responsibility to catch the opportunity of domestic and international markets to provide high quality ferroalloy products to customers. With abundant experience, certified quality and dependable service, Huatuo metallurgy is through these strengths that have expanded our abilities and supported our customers for over 20 years. Our customers depend on Huatuo metallurgy for the best in ferro silicon briquette, silicon slag, silicon carbide and other ferro alloy products. What is important, we are also the trustiest source for providing ferro alloy products worldwide.

Huatuo metallurgy is a trust and professional supplier. We are a partner you can trust for competitive price and responsive service. We will get to know your business, applications and ferro silicon needs while developing a project that satisfies those needs allowing us to help you achieve its production and profitability goals. The important benefit to you is that we help our customers deliver better products faster with less production and operational risk. We offer full service silicon carbide supply and service. Huatuo metallurgy is proud to offer service and top-of-the-line products to our customers all over the world. If you’re looking for a metallurgy company with the experience and reputation to outperform your expectations, trust Huatuo metallurgy.

Our Advantages

Why Customers Purchase Ferro Silicon from Huatuo Metallurgy?

For lots of customers the decision to purchase ferro silicon from Huatuo metallurgy, there are four factors as below:- Quality

- Reliability

- Availability

- Deliverability

The high-quality ferroalloy products meet the requirements of the specifications used in steel making deoxidizer, casting materials and refractory. We also do special orders for customers’ extreme demands.

Huatuo metallurgy has a reputation for reliability that built on the experience of thousands of engineering companies applying Huatuo metallurgy over two decades.

Availability. Huatuo metallurgy has a variety of ferro alloy products. Hence, we have in the number of ferro silicon, silicon carbide, nodulizer and silicon briquette in stock and the options in different models and specifications.

Deliverability. We sell a lot of metallurgy each year. We ship a lot of it to customers all over the world. We know the vessels, the schedules, the issues. It means that we can focus on cutting delivery times and reducing risks of delays.

- Main Markets

-

Malaysia

Malaysia

South Korea

South Korea

Thailand

Thailand

Viet Nam

Viet Nam

- Main Product

Related Products

Silixen Series

silica powder pure SiO2 99.99%

Silica Sand

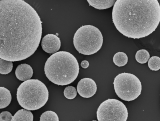

Spherical Fused Silica Powder

Silica sand for precision casting

China

China