| Model (mm) | Feed size (mm) | Discharge size (mm) | Capacity (t/h) | Rotation (r/m) | Motor (KW) | Weight (ton) |

|---|---|---|---|---|---|---|

| PEF-150×250 | 0-125 | 10-40 | 1-3 | 250 | 5.5 | 0.8 |

| PEF-200×300 | 0-180 | 15-50 | 2-6 | 260 | 11 | 1.4 |

| PEF-250×400 | 0-210 | 20-80 | 5-20 | 300 | 15 | 3.0 |

| PEF-400×600 | 0-350 | 40-100 | 15-60 | 275 | 30 | 6.5 |

| PEF-500×750 | 0-425 | 50-100 | 40-110 | 275 | 55 | 11.3 |

| PEF-600×900 | 0-480 | 65-160 | 90-150 | 250 | 75 | 17.6 |

| PEF-750×1060 | 0-630 | 80-160 | 100-250 | 250 | 90-110 | 27.5 |

| PEF-900×1200 | 0-750 | 95-165 | 120-300 | 200 | 110-160 | 52 |

| PEF-1000×1200 | 0-850 | 110-260 | 180-350 | 200 | 110-160 | 57 |

| PEF-1200×1500 | 0-1020 | 150-300 | 300-500 | 180 | 180-220 | 100 |

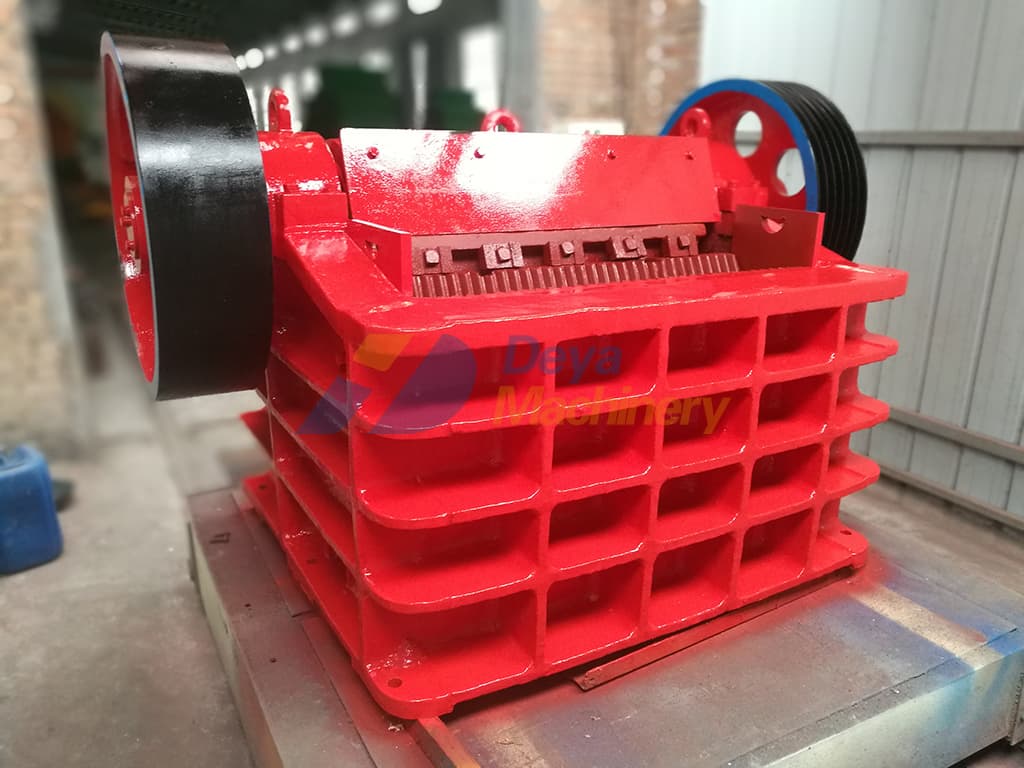

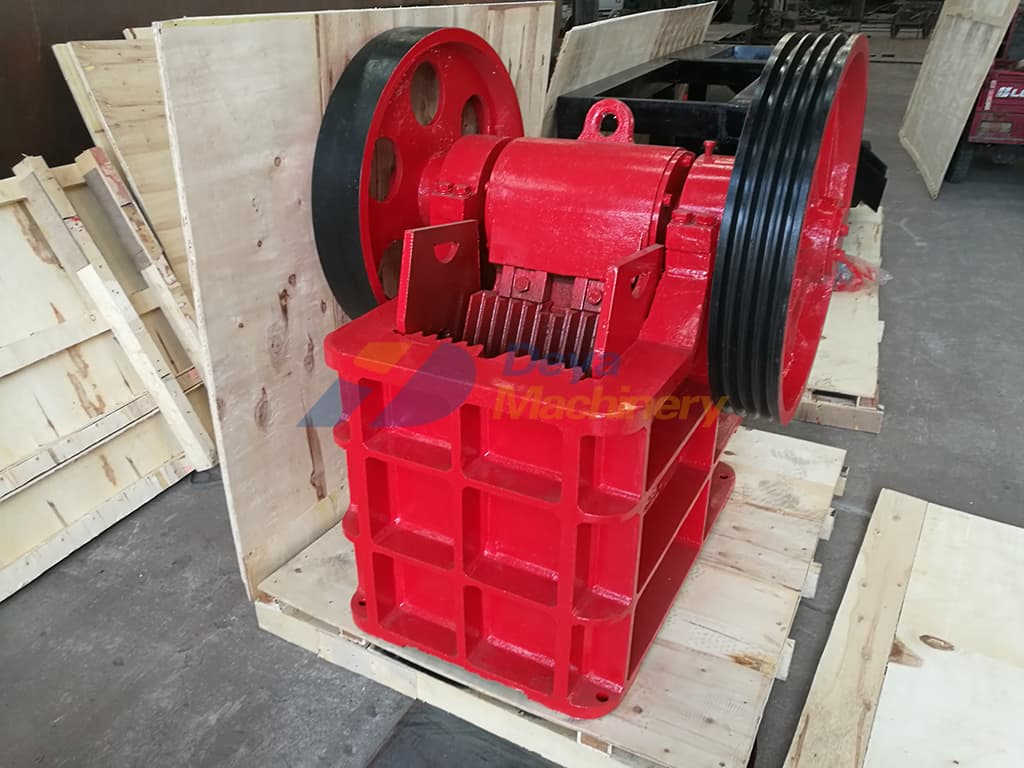

Jaw Crusher

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Mining Machinery

Henan Deya Machinery Co., Ltd.

- Verified Certificate

-

7

| Product name | Jaw Crusher | Certification | - |

|---|---|---|---|

| Category | Mining Machinery | Ingredients | - |

| Keyword | jaw crusher , stone jaw crusher , primary jaw crusher , jaw stone crusher | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Introduction and Benefits

Jaw Crusher is the traditional product in crushing and beneficiation plants, it is suitable for crushing a variety of soft and hard ores and rocks. PEF series are for primary crushing, while PEX series are for secondary crushing.

- Excellence in casting engineering

- Excellent material intake capacity

- Easy installation & maintenance

- High production and reduction

- Reliability, high availability

Working Principle

A jaw crusher uses compressive force for breaking of particle. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates. A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw, called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber. The movement of the swing jaw can be quite small, since complete crushing is not performed in one stroke. The inertia required to crush the material is provided by a weighted flywheel that moves a shaft creating an eccentric motion that causes the closing of the gap.

Introduction and Benefits

Jaw Crusher is the traditional product in crushing and beneficiation plants, it is suitable for crushing a variety of soft and hard ores and rocks. PEF series are for primary crushing, while PEX series are for secondary crushing.

- Excellence in casting engineering

- Excellent material intake capacity

- Easy installation & maintenance

- High production and reduction

- Reliability, high availability

Working Principle

A jaw crusher uses compressive force for breaking of particle. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates. A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw, called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber. The movement of the swing jaw can be quite small, since complete crushing is not performed in one stroke. The inertia required to crush the material is provided by a weighted flywheel that moves a shaft creating an eccentric motion that causes the closing of the gap.

Primary Jaw Crusher

Secondary Jaw Crusher

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- https://www.deyamachinery.com

- Address

- Gongyi, Zhengzhou, Henan, province, P. R. China.

- Product Category

- Other General Industrial Equipment

- Year Established

- 2005

- Company introduction

-

Henan Deya Machinery Co., Ltd. is a professional manufacturer of crushing equipment, mineral processing equipment and their spares; the company was established in early 1990 and locates in Baihe Industrial Zone, Gongyi, Zhengzhou, Henan province, P. R. China; the plant with an area of twenty thousand square meters which includes eight thousand square meters of standard industrial workshops.

Deya Machinery lays much emphasis on quality and service; the company has acquired ISO 9001: 2008 certificate, and it has independent quality control department and after sale service department. Main equipment include Jaw Crusher, Ball Mill, Magnetic Separator, Flotation machine, Trommel Screen, Belt Conveyor, construction machinery equipment and their spares. Main processing equipment includes φ8.0m, φ5.0m hobbing, φ6.3m, φ5.0m heavy vertical lathe, φ3.5m, φ2.5m CNC vertical lathe, φ6.0m × 18.0m barrel sleeper, φ220mm, φ160mm boring, φ160mm boring and milling machine, CNC cutting machine, milling machine, automatic welding center, 60mm × 3m Bending and other NTU, fine, thin processing equipment.

As a customer oriented company, Deya People with high level of professionalism, and responsibility; total satisfaction from clients becomes the top priority, and long-term cooperation is what we always sought and cherished for. The products have exported to over 30 countries like Indonesia, Philippines, Vietnam, India, Pakistan, Iran, Turkey, Tanzania, Zambia, South Africa, Ghana, Peru, Bolivia, Mexico, Chile, etc. We sincerely hope can establish business cooperation with your esteemed company in the long run.

- Main Product

Related Products

Gearbox planetary assy for Mitsubishi MG400 grader

_2.png)

Turbowin Turbo Compressor (WH Series)

Hydraulic Breaker

Taper Anti-Slanting Adjusting Roller Group for Belt Conveyor

Cummins engine parts

China

China