sand paper (Metal Application)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Abrasives

Deerfos

- Verified Certificate

-

6

| Product name | sand paper (Metal Application) | Certification | - |

|---|---|---|---|

| Category | Abrasives | Ingredients | - |

| Keyword | coated abrasive , coated abrasive film , coated abrasive cloth and paper , sand paper | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

DEERFOS Metalist (Metal application products)

Our Premium Line (BORA Series)

1. BORA 3

* It is a ceramic abrasive product constructed on a very flexible J-weight cloth backing.

* Multidirectional grinding.

* Most flexible ceramic belts ideal for curvy application such as cutlery, surgery scissors.

* Full ceramic grain is designed to operate much cooler, reducing metal discoloration.

* Specialized top coating for heat resistance.

2. BORA 6

* A specialized top coating belt constructed of high performing zirconia abrasive grain on a heavy

cloth backing.

* New perple coating reduces clogging, friction and heat built up.

* Specialized for soft metals.

* High density of zirconia grain mixed sintered.

* Extremely long lasting.

* Applications include dimensioning and stock removal.

* Longer life time and improved productivity on mild steels and stainless steels.

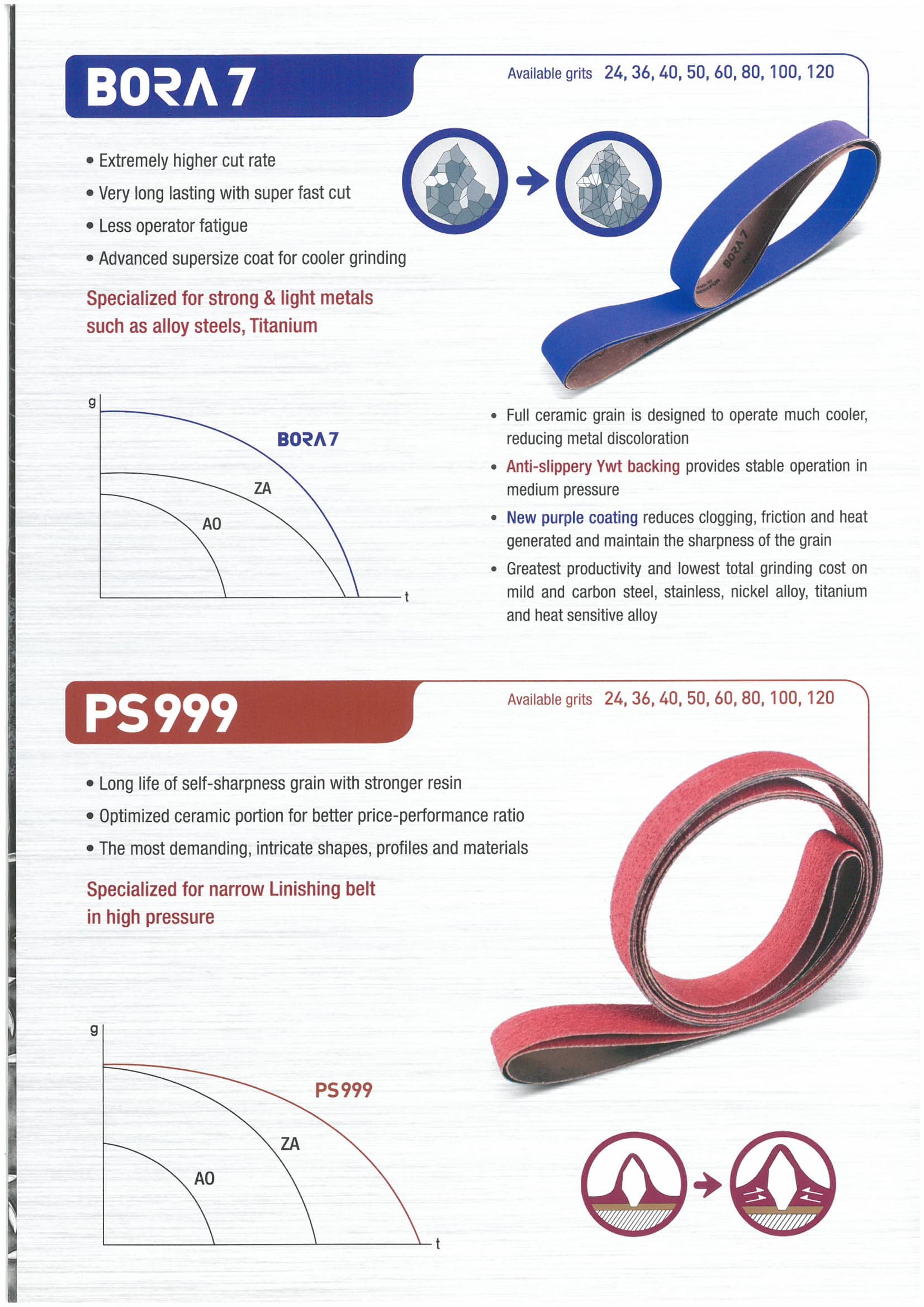

3. BORA 7

* Extremely higher cut rate.

* Very long lasting with super fast cut.

* Less operator fatigue.

* Advanced supersize coat for cooler grinding.

* Full ceramic grain is designed to operate much cooler, reducing metal discoloration.

* Anti slippery Y-weight backing provides stable operation in medium pressure.

* New purple coating reduces clogging, friction and heat generated and maintain the sharpness of the grain.

* Greatest productivity and lowest total grinding cost on mild and carbon steel, stainless, nickel alloy,

titanium and heat sestive alloy.

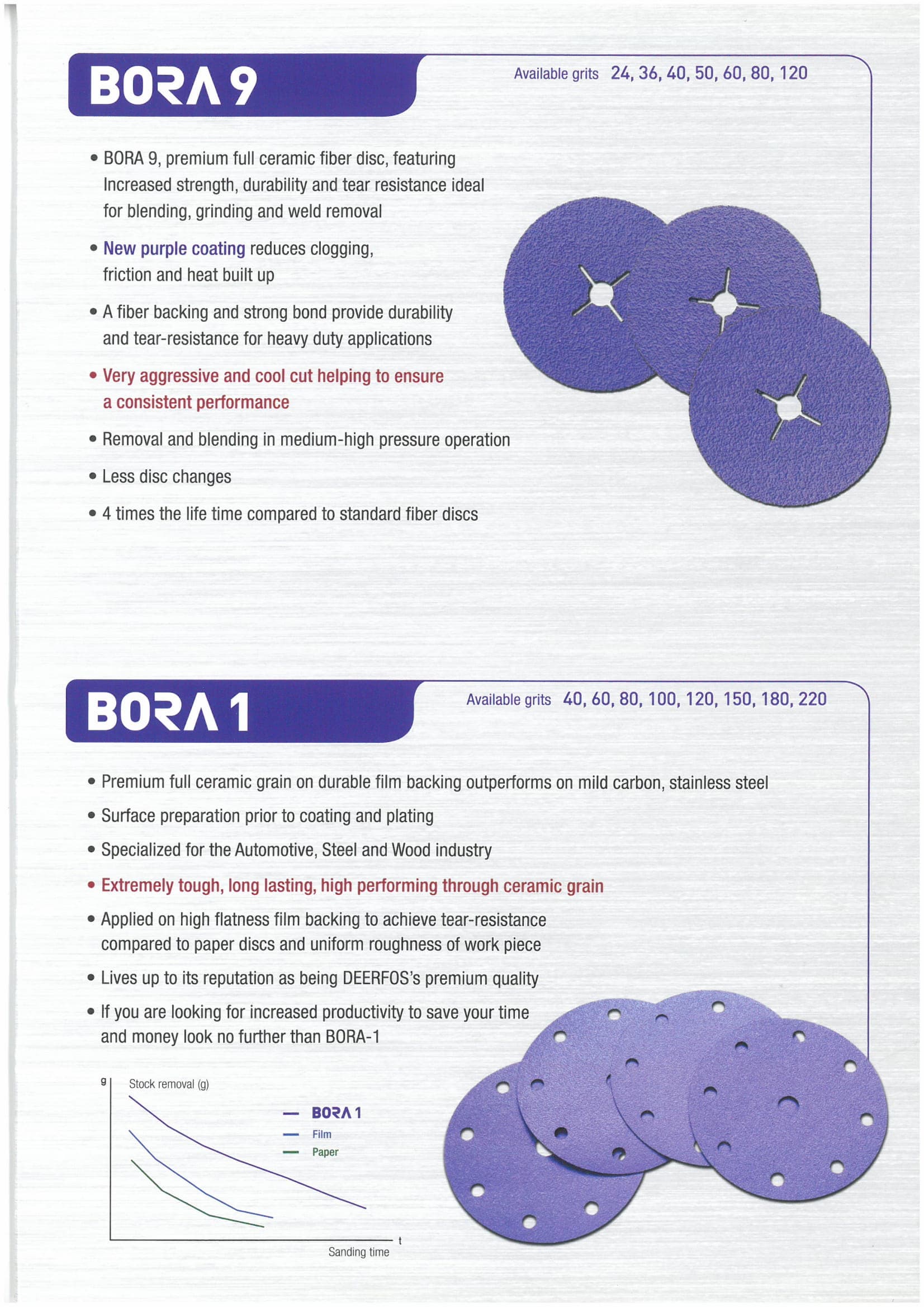

4. BORA9

* BORA9, premium full ceramic fiber disc, featuring increased strength, durability and tear resistance ideal

for blending, grinding and weld removal.

* New purple coating reduces clogging, friction and heat built up.

* A fiber backing and strong bond provide durability and tear resistance for heavy duty applicatins.

* Very aggressive and cool cut helping to ensure a consistent performance.

* Removal and blending in medium-high pressure operation.

* Less disc changes.

* 4 times of the life time compared to standard fiber discs.

5. Other Products for Metal.

* Besides the BORA seires, we have other products for Metal.

* J-weigt, X-weight, Y-weight backing products.

* Zirconia, Ceramic grain products.

* The products are on standard lines at resonable prices.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Ho-Cheol Yoon

- Address

- Seon-Am BLDG, 84, Yeongdeungpo-ro, Yeongdeungpo-gu, Seoul, 07291, Republic of Korea

- Product Category

- Abrasives

- Year Established

- 1963

- No. of Total Employees

- 501-1000

- Company introduction

-

Customer Satisfaction Has Been Our Top Priority For More Than 50 Years.

Founded in 1963, DEERFOS is a manufacturer of coated abrasive products. DEERFOS quickly became a leader in the domestic coated abrasive market in Korea. Our growth can be directly attributed to strict quality controls and continuous research and development. We are constantly trying to provide even better service to meet all the requirement of our customers. Our pioneering efforts have led to success in developing new coated abrasive products and have provided DEERFOS the opportunity to make a positive impact in the markets around the world. Our efforts and technological investment have resulted in increased customer satisfaction and TRUST globally. DEERFOS will continue to strive for better customer satisfaction while maintaining our goal of TRUST among our customers.

The DEERFOS Brand Is Synonymous With Quality And Customer Satisfaction.

Since its foundation, the focus of DEERFOS has been to develop brand recognition. We are proud to say that our years of diligent effort and technological advancements have made the DEERFOS brand top ranked in the abrasive industry worldwide. The DEERFOS brand is associated with quality, consistency, value, and satisfaction. In order to provide services to a broad customer base. DEERFOS has establishing a manufacturing system that allows us to have the ability to service our broad customer base with solution to all their abrasive needs while consistently manufacturing the same high level of quality. Our dedication to this technology has allowed the DEERFOS brand to be recognized for its quality, performance and value.

The Power Of DEERFOS Stands Out From The Competition.

Coated abrasive are used in a wide range of applications including wood working, metal fabrication, glass and automotive. Each coated abrasive product we developed is designed to be the most effective for its intended application. As new applications for coated abrasive emerge, DEERFOS works endlessly to develop new products to meet the requirements of our customers. The DEERFOS R&D Center is continuously developing new coated abrasive items while also upgrading the existing products. These efforts along with our manufacturing system controls have made the DEERFOS brand widely requested by around the world.

DEERFOS Around The World.

DEERFOS was established in Seoul, South Korea in 1963 and now has facilities around the world. Currently we have 3 factories (Korea, China) and 7 branches including India, Indonesia, Poland, USA, Brazil, Mexico, Colombia. In addition, we are represented by agents in over 80 countries worldwide. This broad representation and distribution system allows us to provide services effectively for all of our customers needs. With a direct investment in China, DEERFOS is now ranked No.1 in the Chinese market for coated abrasives while our continued efforts in other industrialized countries have helped to increase our global market share.

- Main Markets

-

Australia

Australia

Brazil

Brazil

Indonesia

Indonesia

Italy

Italy

Mexico

Mexico

Pakistan

Pakistan

Poland

Poland

Thailand

Thailand

U.S.A

U.S.A

Viet Nam

Viet Nam

- Main Product

Related Products

white fused alumina section sand

Polishing Film : XPS-P3

Steel Shot, Steel Grits

98% Black Silicon Carbide SiC for Abrasive Products

Xonite Diamond Sheet

South Korea

South Korea