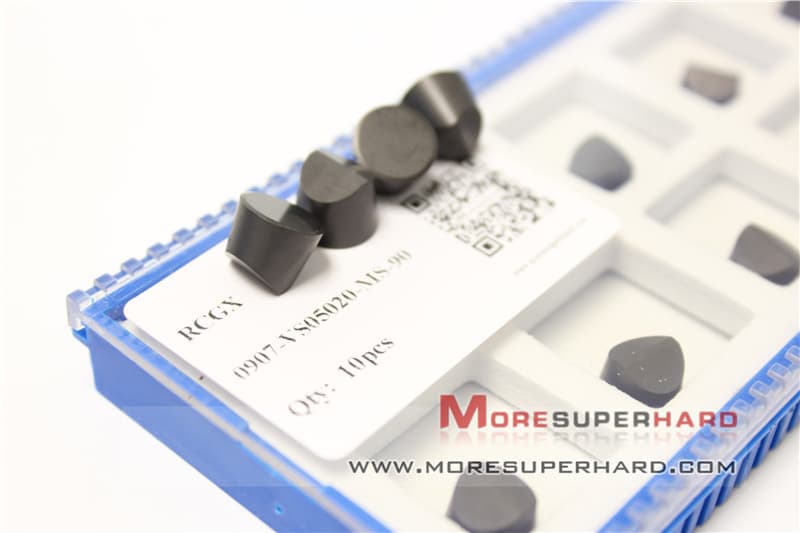

Solid CBN inserts RCGX090700 for Processing high-speed roll

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Moresuperhard

- Payment Terms

- Others,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Abrasive Tools

Henan More Super Hard Products Co.,Ltd

- Verified Certificate

-

7

| Product name | Solid CBN inserts RCGX090700 for Processing high-speed roll | Certification | - |

|---|---|---|---|

| Category | Abrasive Tools | Ingredients | - |

| Keyword | cbn inserts , solid cbn inserts , processing high-speed roll , rcgxrcgx | Unit Size | - |

| Brand name | Moresuperhard | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Name: Solid CBN inserts

Brief Introduction: solid cbn inserts are used for rough and finish machining of hard steel ,cast iron and hard surface workpiece.

type: RNMN,SNMN,TNGN,CNMN,RCMN,RCMX

application: turning hard steel,cast iron

Details

Cubic boron nitride inserts (CBN Inserts) is a high-performance type of cutting tool material from a polycrystalline mass. CBN is a high hardness, high heat resistance crystal synthesized by boron and nitrogen under high temperature and high pressure.

Applications of solid CBN inserts:

Processing workpiece: rough and finish machining of the hard steel ,cast iron and hard surface workpiece.

Processing materials: ferrous materials possessing hardness from approximately 45 HRC as well as gray cast iron, Cr-chilled cast iron and wear alloys on a cobalt, nickel or iron basis.

Usages of PCBN inserts:

1.PCBN bladesare mainly using in processing of hardened steel whose hardness is of HRC50-60. such as: carbon tool steel, bearing steel, die steel, high-speed steel and so on. It also using in processing of gray cast iron, ductile iron, chilled cast iron, and other high temperature alloy and so on.

2.PCD toolsare using in cutting of non-ferrous metals (such as copper, aluminum, magnesium, etc.) and non-metallic materials (such as fiberglass, ceramics, reinforced plastics, etc.)

Products feature:

1.PCBN cutting tools, which also known ascubic boron nitride(CBN) blade, has high hardness and excellent thermal stability.

2.PCBN inserts’ cutting temperature can reach 1300°C.

3.PCD tool, also known as polycrystalline diamond blade, has high hardness, excellent wear resistance, low friction coefficient, and excellent thermal conductivity.

Compared with Carbide inserts and Ceramic inserts, when Milling Cast iron and Hardened steel materials, the CBN milling inserts has more advantages:

Advantages:

- Professional Edges design for Milling; Super-precision Edges preparation,

- Faster Material Removal rate,

- Longer Lifetime,

- Lower Composite Cost.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Others,T/T,Western Union | Shipping time | Negotiable |

- President

- Joe

- Address

- B906,Wanda Plaza, Zhongyuan Road, Zhengzhou, Henan, China

- Product Category

- Other Machinery Parts

- Year Established

- 2014

- Company introduction

-

"Henan More Super Hard Products Co.,Ltd" is specialized in manufacturing and marketing of diamond & CBN tools.

- Main Product

Related Products

Abrasives Flap Disc

Engineered Stone Polishing Pad

Xonite Diamond Sheet

Abrasive wheel

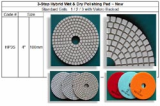

3 Step Hybrid Wet Dry Polishing Pad

China

China