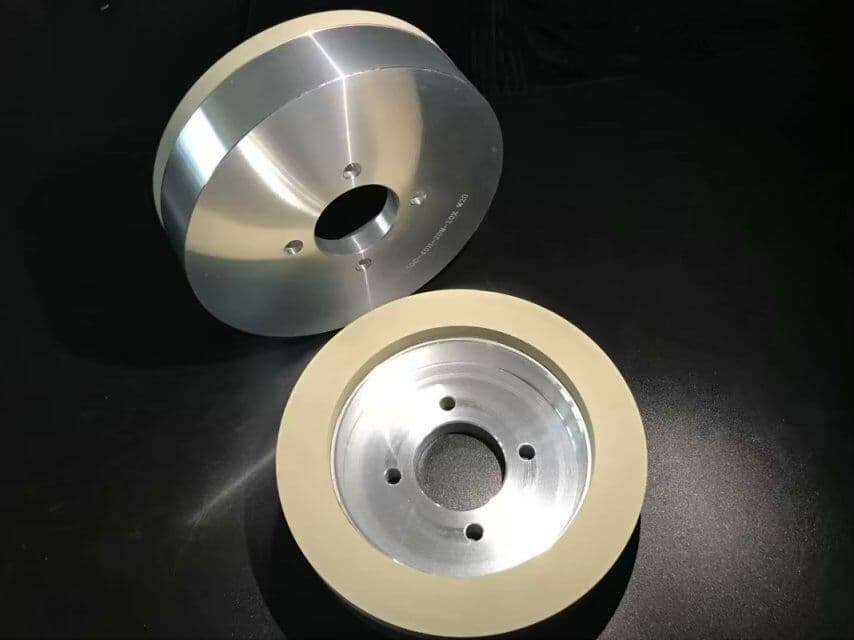

vitrified bond diamond Cup wheel 6A2

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Abrasive Tools , Abrasives

More super hard product company

- Verified Certificate

-

7

| Product name | vitrified bond diamond Cup wheel 6A2 | Certification | - |

|---|---|---|---|

| Category |

Abrasive Tools

Abrasives |

Ingredients | - |

| Keyword | 6a2 cup wheel , vitrified bond , vitrified bond diamond wheel | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

vitrified diamond grinding wheels Detail:

Our vitrified diamond grinding wheels for PCBN and PCD tools have been produced in-house for many years. We production Superior quality grinding wheels for you. Increased feed rates, higher shaped effect, also has less heat making are just some of the advantages of our grinding wheels .

We have a team to contral the working conditions, so the vitrified bond diamond grinding wheels for PCBN and PCD with longer life, superior edge quality.

Another, we supply for rough PCD/PCBN grinding by using 600, 800, 1000 mesh diamond. It Shows excellent performance with sharpen cutting, high wear resistance and no chip on wheel.

Fine grinding is using 3000, 4000, 5000 mesh diamond giving higher performance on PCD/PCBN cutters or workpiece.

Vitrified bond diamond wheel features

A. high strength, good heat resistance,

B. cutting sharp, high grinding efficiency,

C. Vitrified grinding process is not easy to heat and blockage, a small amount of thermal expansion, easy to control the machining accuracy.

Compared with resin bonded grinding wheel

Vitrified bond diamond wheel solved the problem of low service life of resin diamond wheel, low grinding efficiency, abrasive change and odor in grinding process. Vitrified bond diamond wheel in the manufacturing process can be adjusted on the hardness and porosity, is conducive to the improvement of grinding performance, through a reasonable ratio and production control, will not produce deformation, it is also the use of the grinding wheel with high precision the reason.

Specification of vitrified bond diamond grinding wheel:

Name | Size | Grit |

6A2 vitrified diamond grinding wheel | 100*40*40*5*10 | W20/28/40/10/5 |

100*40*40*10*10 | W20/28/40/10/5 | |

125*40*40*5*10 | W20/28/40/10/5 | |

125*40*40*7*10 | W20/28/40/10/5 | |

125*40*40*10*10 | W20/28/40/10/5 | |

125*40*40*15*10 | W20/28/40/10/5 | |

125*40*40*20*10 | W20/28/40/10/5 | |

150*40*40*3*10 | W20/28/40 | |

150*40*40*5*10 | W20/28/40 | |

150*40*40*10*10 | W20/28/40 | |

150*40*40*15*10 | W20/28/40 | |

150*40*40*20*10 | W20/28/40 |

Application

Mainly used for carbide, PCD, PCBN, ceramics, metal ceramics and other materials processing.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Joe

- Address

- No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, Henan,450001 China

- Product Category

- Abrasive Tools,Abrasives

- Year Established

- 2010

- No. of Total Employees

- 51-100

- Company introduction

-

More Super Hard Products Co., Ltd Is Specialized In Manufacturing And Marketing Of Synthetic Diamond Tools, Cubic Boron Nitride(CBN) Tools, Which Is Widely Used In Petroleum And Geology Industry, Auto Aviation Processing Industry, Electric Processing Industry, Natural Diamond And Jewelry Processing Industry And Other Ultra- Precision Industry .

The Company Production And Sales Of Products Covered Vitrified Bond Tools, Resin Bond Tools, Metal Bond Tools, Electroplated Diamond/CBN Tools, Vaccum Brazed Products, CVD Diamond Tools, Polycrystalline Diamond (PCD) Tools, Cubic Boron Nitride (CBN) Tools.Our Objective Is To Meet All The Customers’ Needs And Help Every Customer Achieve Maximum Benefits. More Brings In Revenue For You, You Win, We Win!

More Super Hard Supplies The Wheels For Several Application Mainly:

* Carbide Round Tools On CNC Machines : Flute Grinding, Gash Grinding, End Facing, Clearance Angle And Cylindrical Grinding .

* Insert Grinding For Machines Such As: AGATHON, WENDT, HAAS, WAIDA And EWAG.

* Woodworking Saw Blade And Tools .

* HSS Tools .

* Cutting Wheels.

- Main Product

China

China

_2.png)