ZFA Zirconia fused alumina corundum aluminum oxide

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Haixu Abrasives

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Abrasives

Zhengzhou haixu abrasives co.,ltd

- Verified Certificate

-

10

| Product name | ZFA Zirconia fused alumina corundum aluminum oxide | Certification | - |

|---|---|---|---|

| Category | Abrasives | Ingredients | - |

| Keyword | zirconia aluminum oxide , zirconia corundum , zfa , zirocnia fused alumina | Unit Size | - |

| Brand name | Haixu Abrasives | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

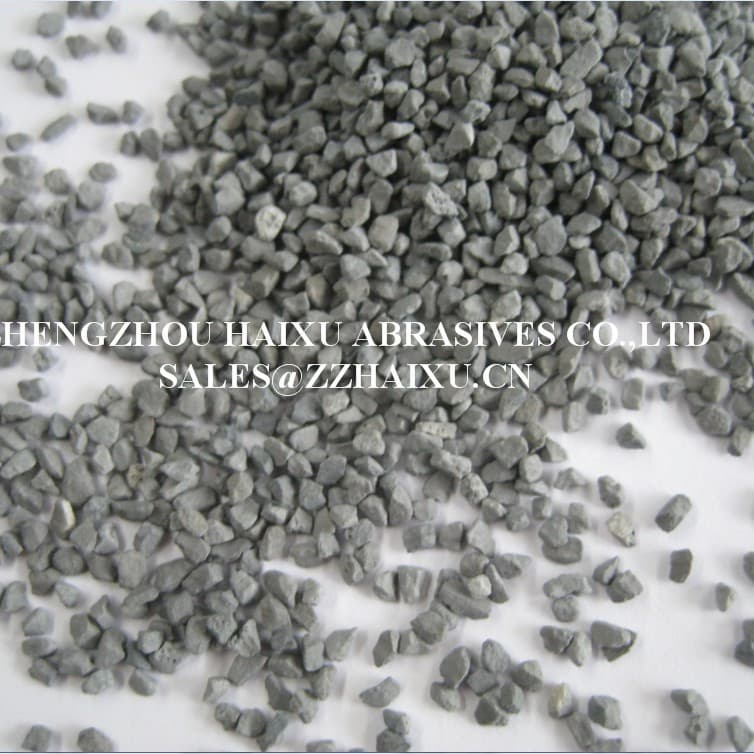

ZFA Zirconia fused alumina corundum aluminum oxide

Chemical Composition(%)

Items | Al2O3 | ZrO2 | TiO2 | Fe2O3 | SiO2 |

ZA25 | 68-72 | 24-30 | ≤1.5 | ≤0.5 | ≤1.0 |

ZA40 | 55-57 | 35-44 | ≤1.5 | ≤0.5 | ≤1.0 |

Physical Properties

Crystal Form | Monoclinic,tetragonal system |

Reaction with acid and alkali | no |

Reaction with carbon | Forming carbide since 1650C |

Color | Grey |

True Density | 4.20g/cm3 |

Bulk Density | 2.18g/cm3 |

Moh's hardness | 9.0 |

Knoop hardness | 1450-2000kg/cm2 |

Melting point | 1900C |

Maximum service temperature | 1700C |

Specific heat capacity(cal/g.C) | 0.2205(50-500C) |

Heat conductivity | 0.2718 cal/cm2.sec.C |

Linear expansivity(X10-6) | 6.82(100-700C) |

Main Applications

1.Making zircon fused alumina brick and building materials

2.Used for making bonded abrasives products,and process of grinding,sandblasting,surface treatment of metal products and other materials.

3.With good melt erosion resistance,Zirconia fused alumina has good grinding effect on steel,iron casting,heat resistant steel and other alloy materials.

4.Zirconia fused alumina can be made for heavy duty Zirconia fused alumina grinding wheel,snagging,cutting disc,Fiber disc,grinding rails,high speed abrasive belts etc

5.Used for making coated abrasives products,

6.Used for making lapping paste,polishing wax,emery cloth,sandpaper etc

Available Sizes:0-0.5mm 0.5-1mm. 1-1.5mm 1-2mm 1-3mm

F4 F5 F6 F7 F8 F10 F12 F14 F16 F20 F22 F24 F30 F36 F46 F54 F60 F70 F80 F90 F100 F120 F150 F180 F220

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Yingtao Feng

- Address

- A-801 Kaixuanmen Tongbai South Road

- Product Category

- Abrasives

- No. of Total Employees

- 51-100

- Company introduction

-

Zhengzhou Haixu Abrasives Co.,ltd ,founded in 1999, with more than 80 Staff including 10 professional and technical personnel, is specialized in production and sale of abrasives. Our main products are white fused aluminum oxide, brown fused aluminum oxide,black aluminum oxide and silicon carbide and other related products running under the certifications G B , I S O,F E P A and J I S . At present, our annual production capacity is about 30000tons and sales exceeded 100 millions. Our company owns science Management system and perfect quality control system with all kinds of testing equipment such as Omec, slap-sieve and microscope.

In order to serve our international customers better and make our abrasive products to global market widely, we established Henan Sicheng Co.,ltd in 2010,which is specialized in international business in abrasive field. Since its establishment, until now we have supplied our abrasives products to more than 200 customers from over 40 countries, and received a favorable report from customers both home and abroad

All staff from Haixu Abrasives hope to cooperate with you sincerely, and finally to get win-win situation.

- Main Markets

-

Indonesia

Indonesia

Malaysia

Malaysia

Saudi Arabia

Saudi Arabia

South Korea

South Korea

Viet Nam

Viet Nam

- Main Product

Related Products

sand paper (Metal Application)

_2.png)

Xonite Dendroid Brush(cleaning)

Cast Stainless Steel Shot

white fused alumina fine powder

Xonite Diamond Sheet

China

China