Pvc Celling Panel Line

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- TPM

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Zhangjiagang tiger machinery co., ltd

- Verified Certificate

-

7

| Product name | Pvc Celling Panel Line | Certification | - |

|---|---|---|---|

| Category |

Plastic Product Making Machinery

Other Plastic Product Making Machinery |

Ingredients | - |

| Keyword | pvc sheet and foamed panel extrusion line , pvc rooftile production line , pvc wavy board , pvc wall panel line | Unit Size | - |

| Brand name | TPM | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Pvc Celling Panel Line

APPLICATION

PART I. Introduction of PVC ceiling wall panel making machine production line

1. We are the most professional manufacturer of PVC ceiling making machinery in china, more than 50% china cities has our PVC ceiling panel making machine.

2. Normally the width of PVC ceiling panel is 200mm, 250mm, 300mm, 400mm, 600mm etc... To suggest you the most suitbale PVC ceiling machine, please tell us size of your panel first. It is important.

3. We can offer you turnkey solution of build a PVC ceiling panel factory.

PART II. THREE TYPES OF SURFACE TREATMENT FOR PVC CEILING PANEL:

1. Two color printing: First you will need an extra printing machine, and this printing machine work separately, you need first produce white color PVC ceiling panel, and then use the printing machine to get different design pattern PVC ceiling.

2. Lamination: Use glue to stick the design paper on the surface of PVC ceiling panel. It is connected with the PVC ceiling panel extrusion line.

3. Hot stamp print: Transfer design pattern from hot stamping foil to the surface of PVC ceiling tile. It is connected with the PVC ceiling panel production line.

PART III. PVC CEILING PANEL MANUFACTURING PROCESS:

STEP 1:

Raw material mixing according to the formula.

STEP 2:

Use PVC ceiling panel making machine and 3 kinds surface treatment to get product. you can use hot stamping or lamination or two color printing on the PVC ceiling panel surface to get diffferent design pattern.

STEP 3:

Bad product recycling. During the second step. normally it will occur some waste pruduct, so it will be necessary for you to recycle it.

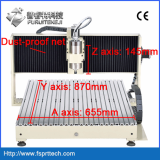

PART IV. MODEL AND PARAMETERS OF PVC CEILING PANEL MACHINE:

Model | 51/113 | 55/110 | 65/132 |

Product width | 200mm-250mm | 200mm-500mm | 250mm-600mm |

Extruder | SJSZ51/102 | SJSZ55/110 | SJSZ65/132 |

capicity per 24h | >800m2 | >1200m2 | >1600m2 |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- chenfeng

- Address

- Leyu Economic Development Zone,Zhangjiagang City, Jiangsu Province,China

- Product Category

- Plastic Product Making Machinery

- Year Established

- 2013

- No. of Total Employees

- 1-50

- Company introduction

-

Zhangjiagang tiger machinery co., ltd. is Located in developed area of Zhangjiagang. It has very convenient and preferable geographic position, with Shanghai at its east.Company is a professional manufacturer of plastic equipment by integrating researching, developing, manufacturing and trading into its business scope. It has strong technical team, perfect system of after-sale service and can offer excellent product quality, which have been praised by all customers.Ceiling panel extrusion machine ; PPR&PE&PVC pipe machine; providing a turnkey solution for mixing and conveying for plastic & rubber industry,environmental-friendly air conveying/mechanical conveying, material automatic weighing & dosing system;Single, double screw extruder, high-speed mixer,drier, feeder, crusher & water cooler, etc.Company has strong technical force, best quality manufacturing equipment and leading research and development capability. Bearing the company tenet being "credit supremely, Customer First and Service at Whole Sides", the company will keep providing existing and new customers with perfect quality service and complete technical supports.

- Main Markets

-

Russia

Russia

- Main Product

China

China