Closed cell Polyethylene Foam XPE IXPE ESD foam Manufacturer

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- closed cell polyethylene foam, closed cell esd polyethylene foam, closed cell polyethylene foam manufacturer

- Category

- Electronics Packaging

Suzhou Sinkery Electronic Technology Co.,Ltd.

- Verified Certificate

-

7

| Product name | Closed cell Polyethylene Foam XPE IXPE ESD foam Manufacturer | Certification | - |

|---|---|---|---|

| Category | Electronics Packaging | Ingredients | - |

| Keyword | closed cell polyethylene foam , closed cell esd polyethylene foam , closed cell polyethylene foam manufacturer | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Product details

| Material | XPE foam packaging |

| Type | Conductive IXPE Foam |

| Thickness | 1-100mm |

| Color | Black |

| Surface Resistance | 103-109 Ω |

| Certificate | SGS, ISO9001, ROHS |

| Product Keywordsuct Keywords | xpe foam packaging |

Features:

IXPE Foam

1. Wich conduction path / network inside. excellent antistatic performance;

2. It promotes the rapid release of electrostatic without using the environmental humidity. anti-static performance is not

affected by the environmental humidity;

3. Buffer good performance: independent and fine pore closure;

4. High temperature resistance: IXPE maximum temperature 120°C

5. Chemical resistance: resistant to organic solvents, acids, bases, etc.;

6. No chemical corrosion: It has no corrosion to the components and packaging;

7. Heat insulation, sound insulation, water absorption, moisture;

8. Good processing performance, easy molding.

Material Specification of Conductive PE Foam

1.Basic Process

The said product is a close-cell, conductive foam. It is produced by compounding the PE resin with conductive fillers &

blowing agents to extrude certain sheets,then cross-linking and foaming. The basic process can be summarized to the following:

1.1 Pellitizing master batch by compounding PE resin with carbon black and AC foaming agents;

1.2 Extrude the said batch to make certain sheets with different thickness & width;

1.3 Crosslink the said sheets under electric beam;

1.4 Make the crosslinked sheets foam in foaming furnac

2.Norminal size

2.1 Normal size:

10m×1.2m×8mm 10m×1.2m×5mm

2.2 Special size:

2.2.1 Special thickness such as 25mm, 20mm,15mm and 10mm should be ordered

2.2.2 Small length, width and profile product are to be ordered.

3. Characteristics

3.1 Excellent ESD effect because its interior conductive lattice

3.2 Able to leaking static electricity rapidly and free of environmental humidity

3.3 Long time and even Permanent ESD duration(at least 3 years).

Why choose us?

1.We are specialized in producing ESD Foam packaging since 2009, so we are more professional.

2. We can provide a reasonal price for our products because we are a factory-direct.

3. No MOQ for our products. So do not worry about if your quantity is not high enough.

4. We have advanced production, processing equipment, with strong production capacity, so the delivery date

can be guaranteed.

5.We had won the trust and support from our new and old customers with excellent service, reasonable prices.

Quality assurance:

1. Vinner is equiped with world advanced computer driving production lines

2. Whole set of pure water processor line featured with RO anti-saturation and advanced testing devices

3. Manufactured in Class 100,000 Cleanroom.

Contact Details:

Name: Lisa

Mobile: 18871173169 (WhatsApp)

Skype: lisa520huanghua

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- LIU FENG

- Address

- No. 399, Hean Road, Puzhuang Development Zone, Linhu Town, Wuzhong Area, Suzhou, Jiangsu, China (Mainland)

- Product Category

- Protective Packaging

- Year Established

- 2009

- No. of Total Employees

- 101-500

- Company introduction

-

<p>Located in the beautiful city of Wuzhong District in Suzhou, covers an area of 3000 square meters. Our company is a research and development, production, sales and service in one, silica gel foam, plastic foam, rubber foam material based cushioning packaging products manufacturers. The company has advanced production and processing equipment, strong production capacity. The production of products with anti-static, conductive, cushion, corrosion proof, heat insulation, sound-absorbing, sealing, high temperature resistance, flame retardant, non-toxic, antibacterial and other characteristics, widely used in electronics industry, electronic instruments, household appliances, petroleum industry, military industry, textile industry, mining industry, medical equipment and other needs of all electrostatic isolation and the field of shielding.

We have a high level of professional and technical personnel and high-quality staff, excellent production equipment and processing equipment, to provide high-quality products for customers, with our excellent service and reasonable price, won the new and old customers trust and support, we sincerely thank sense of new and old customers has been the support and we are willing to help in the future to obtain a win-win situation in the basis of equality and mutual benefit, mutual aid, integrity of the.

- Main Product

Related Products

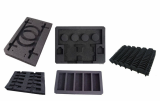

Anti-Static IXPE/EVA Corrugated Accessories tray box

Compound PE + HIPS Sheet or Roll

VCI Chip GVC100

Eco-Friendly Pulp Molded Electronics Packaging Trays

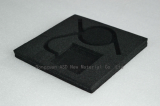

Conductive IXPE Foam tray

China

China