Gas metal arc welding

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- overlay, welding, gmaw, hard facing material hard metal

CnH Welding

- Verified Certificate

-

8

| Product name | Gas metal arc welding | Certification | - |

|---|---|---|---|

| Category |

Flanges

Valves Other General Industrial Equipment Welding Equipment Other Welding & Soldering Supplies |

Ingredients | - |

| Keyword | overlay , welding , gmaw , hard facing material hard metal | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

* Gas metal arc welding (GMAW) *

Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) welding or metal active gas (MAG) welding, is a welding process in which an electric arc forms between a consumable wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to melt and join.

Along with the wire electrode, a shielding gas feeds through the welding gun, which shields the process from contaminants in the air. The process can be semi-automatic or automatic. A constant voltage, direct current power source is most commonly used with GMAW, but constant current systems, as well as alternating current, can be used. There are four primary methods of metal transfer in GMAW, called globular, short-circuiting, spray, and pulsed-spray, each of which has distinct properties and corresponding advantages and limitations.

Originally developed for welding aluminium and other non-ferrous materials in the 1940s, GMAW was soon applied to steels because it provided faster welding time compared to other welding processes. The cost of inert gas limited its use in steels until several years later, when the use of semi-inert gases such as carbon dioxide became common. Further developments during the 1950s and 1960s gave the process more versatility and as a result, it became a highly used industrial process. Today, GMAW is the most common industrial welding process, preferred for its versatility, speed and the relative ease of adapting the process to robotic automation. Unlike welding processes that do not employ a shielding gas, such as shielded metal arc welding, it is rarely used outdoors or in other areas of air volatility. A related process, flux cored arc welding, often does not use a shielding gas, but instead employs an electrode wire that is hollow and filled with flux.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Park Hanyoung

- Address

- 226, Tekeunobaeli-gil, Daman-ri, Jillye-myeon, Gimhae-si,Gyeongsangnam-do, Korea

- Product Category

- Other General Industrial Equipment,Pipe Fittings,Pressure Vessels,Valves,Welding & Soldering Supplies

- Year Established

- 2015

- No. of Total Employees

- 1-50

- Company introduction

-

C&H Welding is an expert on the overlay based on special welding.

We are specialized in Corrosion resistance and Hard facing welding by using SMAW, GTAW, FCAW, GMAW, PTA welding processes.

According to customer’s specification / ASME Sec.IX,

WPS(Welding Procedure Specification) development can be offered.

And in order to get high quality, after checking a result of sample that is tested exactly carried on with the valid welding processes, variables by produced WPS,

we perform welding after verifying the results to specify a welding range thereby work can be more effective and best condition.

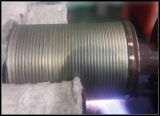

It can be applied to various product such as Roller, Bucket, Cone crusher, shaft, Pressure vessel, tool, Gear, Tubesheet, Ring, Screw, Pipe, Elbow, Tee, Flange, Valve, etc., and various business fields such as steel making, heavy industry, shipbuilding, offshore plant, petrochemistry plant, etc., and it will bring many advantages for cost reduction, long maintenance period, and quality improve.

C&H Welding will do our best to realize customers satisfaction and make the best quality products on the basis of overlay welding technology.

- Main Markets

-

Japan

Japan

- Factory Information

-

C&H Welding

- Main Product

South Korea

South Korea

,_Smartphone_dryer,_heating_mobile_2.jpg)