WC67K NC Hydraulic Plate Press Brake With E21 Controller

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery Parts

Manshan Gilde CNC Machine Tool Co.,Ltd

- Verified Certificate

-

8

| Product name | WC67K NC Hydraulic Plate Press Brake With E21 Controller | Certification | - |

|---|---|---|---|

| Category | Other Machinery Parts | Ingredients | - |

| Keyword | plate bending machine , bending plate machine , bending steel plate | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- GLDMA

- Address

- Ma'anshan City, Anhui Province Dangtu County Bowang New Town area of new materials industrial park

- Product Category

- Brake Pads,Garden Tools

- Year Established

- 2005

- No. of Total Employees

- 1001-2000

- Company introduction

-

"Founded in 2000, GILDE commits to the research and development of sheet metal machinery, pursuing the best quality and performance.Now GILDE has already grown into one of the biggest manufacturers in the sheet metal processing equipment field. Our factory has a considerable scale -covers an area of 76,530 m², with more than 300 employees, also owns an outstanding research and development department including 20 technicians and engineers. ......"

- Main Markets

-

Bangladesh

Bangladesh

Cambodia

Cambodia

Kazakhstan

Kazakhstan

Macao(China)

Macao(China)

- Main Product

Related Products

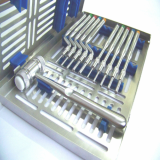

OSTEOTOMES

Electric ULV Sprayer ATOMER 2

Knitted wire mesh Gaskets Seals

EMI Shielding Metal Spring Gasket

Folding Carton Machine / Folder Gluer (LION)

China

China