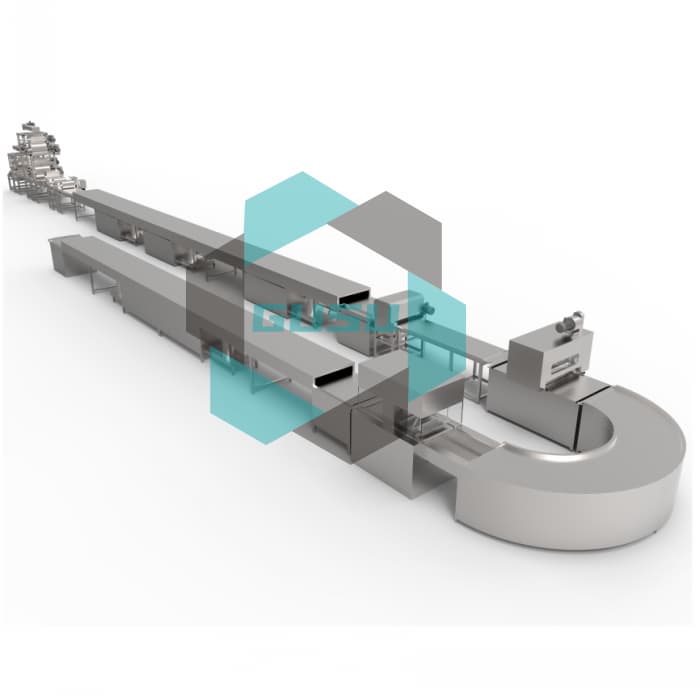

Candy Bar Making Machine Production Line

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- GUSU

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Gusu Food Processing Machinery Suzhou Co., Ltd.

- Verified Certificate

-

8

| Product name | Candy Bar Making Machine Production Line | Certification | - |

|---|---|---|---|

| Category |

Food Processing

Beverage & Wine Processing Machinery Fruit & Vegetable Processing Machines |

Ingredients | - |

| Keyword | candy cofectionery , candy machine , cereal bar , cereal bar machine | Unit Size | - |

| Brand name | GUSU | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 8438200000 |

Product Information

Gusu Candy Bar Automatic Forming Line is designed to meet the fast growing market demand for bar products like Snicker, Nougat, Cereal Bar, Grains Bar, Energy Bar, Fruit Bar, Protein Bar, etc. This line is perfect for both candy bars and bar products intend for diet and nutritional markets. And can also be used to produce everything from nougat or toffee layers, with or without nuts, to granola bars, etc.

Gusu Candy Bar Forming Line is available in three widths: 400, 600 and 800mm. All functions of the bar forming line are regulated by means of one or two PLC control cabinets which is very easy to operate and saves time. Option of incorporating a cooling tunnel for enhanced cooling of the product layers. High quality rollers designed to guarantee both precise forming and optimum cold transfer from the brine tank (Copeland Brand) to the product. The outstanding performance of the cooling equipment and system used for subsequent drying of product layers. Maximum efficiency and reliability and the option of varying cut dimensions, both in terms of length and width.

Modular machine that can be adapted for production of any product the market might require: Energy Bar, Cereal Bar, Granola Bar, Protein Bar, Fruit Bar, Nougat, etc.

Technical Parameters

Model |

TPX400 |

TPX600 |

TPX800 |

Single Roller Width(mm) |

314 |

500 |

535 |

Compound Roller Width(mm) |

314 |

500 |

535 |

Flatten Roller Width(mm) |

310 |

600 |

800 |

Conveyor Belt Width(mm) |

400 |

600 |

800 |

Cooling Tunnel Effective Width(mm) |

400 |

600 |

800 |

Longitudinal Cutter |

1 Unit |

1 Unit |

1 Unit |

Latitudinal Cutter Width(mm) |

500 |

700 |

850 |

Linear Speed(m/min) |

0-5 |

0-5 |

0-5 |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Wang Yongxing

- Address

- No. 2 Yong'an Road, Xuguan Industrial Park, Hi-Tech District, Suzhou City, Jiangsu Province, China

- Product Category

- Fruit & Vegetable Processing Machines

- Year Established

- 1985

- No. of Total Employees

- 51-100

- Company introduction

-

Gusu Food Processing Machinery Suzhou Co., Ltd., formerly known as Gusu General Works of Food Processing Machinery Suzhou, founded in 1969, is also the first enterprise making complete sets of chocolate machinery in China and honored in this industry as "the Mother of Chocolate in China". <br>

Over 45 years, Gusu insists on a corporate philosophy of people-oriented, be loyal to customers and credit management, we aim at the first class equipments and technologies worldwide in the industry, we connected with the food industry, scientific and technological enterprises and universities to make continuous improvements, innovations and development of the products in order to provide better service to customers. Products are sold all over China and more than 80 countries and regions.

Gusu expanded and moved to the new factory in 2014, "Suzhou Food Engineering Research Center" was founded in our new factory.

The purpose of Gusu is daring to scale the heights and striving for industry pioneer, we will continuously work on scientific research and innovations, provide customers with better and better service. We warmly welcome customers worldwide to Gusu to conduct and consult.

- Main Markets

-

Brazil

Brazil

Canada

Canada

Chile

Chile

Ecuador

Ecuador

India

India

Japan

Japan

Peru

Peru

Tadjikstan

Tadjikstan

U.S.A

U.S.A

Uzbekistan

Uzbekistan

- Main Product

Related Products

Auto donuts machine(MR-9900)

Korean Red Ginseng Extract

Bladeless Powder Puverizer

Enterpack(At, semi auto food packaging machine)

Popped rice cake machine, korea pop machine

China

China