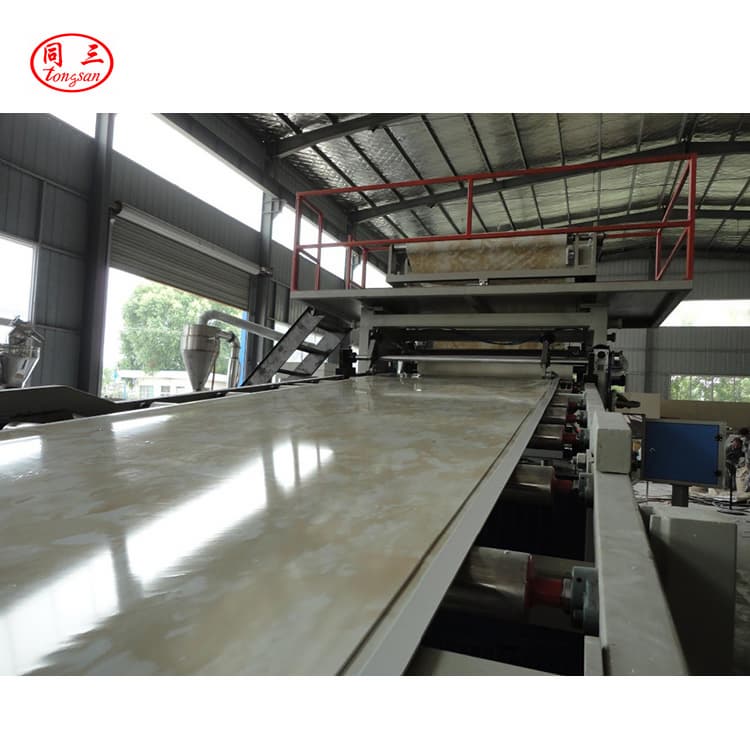

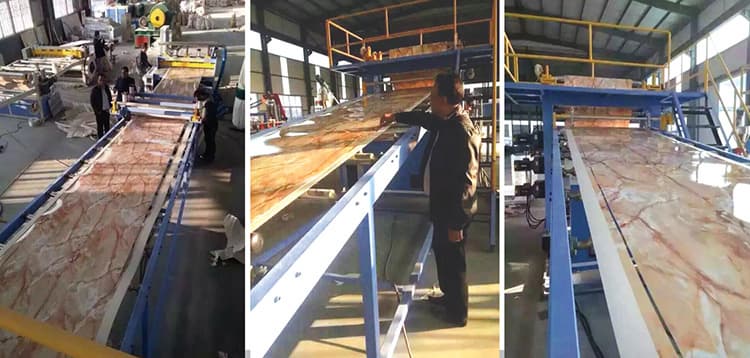

PVC marble sheet board extrusion machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Tongsan

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- pvc marble sheet machine, pvc marble extrusion line, pvc marble board, pvc marble sheet extruder

- Category

- Plastic Product Making Machinery

Qingdao Tongsan Plastic Machinery Co.,ltd

- Verified Certificate

-

8

| Product name | PVC marble sheet board extrusion machine | Certification | - |

|---|---|---|---|

| Category | Plastic Product Making Machinery | Ingredients | - |

| Keyword | pvc marble sheet machine , pvc marble extrusion line , pvc marble board , pvc marble sheet extruder | Unit Size | 3.0 * 5.0 * 20.0 m |

| Brand name | Tongsan | Unit Weigh | 12000 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | 847720 |

Product Information

1. PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line screw adopt the design special mixing material function and high plasticization capacity. This guarantee the uniformity of plastic melting, coloring and high discharge.

2. PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line Mold head adopts throttling design(Cloths rack type), which make more precision of adjusting the thickness of sheet.

3. PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line ±1℃ precision degree of temperature control, can control the plasticization process, thickness and surface smooth of sheet accurately.

4. PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line arrange of roller can be vertical, horizontal of free adjusting type, which can give more selection basing on different thickness of sheet.

5. PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line screw adjusting and oil pressure press-roller double direction adjusting can control the thickness of sheet accurately.

6. PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line double loop cooling system and mold temperature controller are adopted to control pre-roller temperature, by which sheet thickness can be controlled accurately.

7. PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line Line cutting machine can cut the sheet to get accurate length (2400mm).

8. PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line winder adopt high torque motor, which cooperating with four shafts automatic strain control can adjust the winding speed and winding strain to obtain smooth winding. The slitting device can cut sheet free width.

9. PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line automatic measuring meter instrument can set sheet length.

PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line

(Width: 1220mm * Length: 2440mm * Thickness: 3-8mm)

salerjack at tongsanextruder

dot com

Whatsapp 86-1836623-6672

PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line with the advantage of environmental protection, light weight, easy maintenance, no radiation, cheap price, popular decoration use in KTV, Hotel, Leisure facility, Home decoration, Hall, Meeting room, etc.

Our company have advance & rich experience in technology and skills, design and produce in Artificial Marble PVC Decoration Sheet Extruder Machine Line.

PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line: Mixing machine → Material fedding →SJZ-80/156 Conical Twin Screw Extruder Machine → Mold → Three-roller calender (online laminating) → Colling group rollers → Haul off → Transversal Cutter → Edge cutter → Conveyor → UV treatment.

(Note: Other Auxiliary Machine, such as Crusher, Pulverizer, Mixer, will be provided according to client's requirements)

1. Mixing Machine for PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line

Capacity: 650-750kg/h

Paddle material: Stainless steel casting

2. SJZ-80/156 Conical Twin-screw Extruder Machine

Screw material: 38CrMoALA

3. Mould - PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line.

Material : Germany 2738 steel

4. Three-roller calender - PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line

Unwinding Roller Qty: 2pcs

5. Cooling Stacker & Haul-off - PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line.

Cooling Roller Material: Stainless steel

6. Cutting Machine + Stacker - PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line.

Cutter Material: Stainless steel

Knife Material: 9sicr

1. PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line is a kind of special equipment for extruding PVC compound. With different kinds of molds and auxiliary machines, it can produced all sorts of PVC plastic, profile, plate material, sheet material, bar material and granulation.

2. PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line have applied oil cooling system. Barrel is cooled by special wind cooling system.

3. PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line system has applied special computer control. According to customers requirements, most reasonable structure of conical twin screw can be made so as to achieve best plastic city performance and material quality

4. PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line is made by high precision special digital screw miller; extruding property can be highly harmonized. It has firstly introduced advanced technique of producing screw with variable pitch and depth, so that the material can be more softly sheared and cut.

5. The distribution box on PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line is specially designed, pull force bearing is fully imported, and the drive life span can be prolonged. It can bear large extruding pressure.

6. PVC Plastic Artificial Marble Sheet Extrusion Machine Production Line electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems which can be easily eliminated. Thecooling system has applied special design, heat emission area is enlarged, the cooling is rapid, and temperature control tolerance can be ± 1 degree.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Mr.Li

- Address

- West of Yangzhou Road, Jiaozhou

- Product Category

- Plastic Product Making Machinery

- Year Established

- 1997

- No. of Total Employees

- 51-100

- Company introduction

-

<p>

Qingdao Tongsan Plastic Machinery Co.,ltd is an Chinese plastic extruder and plastic extrusion line and plastic recycling machine manufacturer.

Our factory was founded in 1997, since foundation, we focused on the plastic extrusion machine Research and development, we always do our best to improved our machine quality and service level.

With more than 20 years’ development, we have built our features and profession in the plastic extrusion machine field.

1. Plastic corrugated pipe extrusion machine

pp pe pvc single wall corrugated pipe extrusion machine

high speed single wall corrugated pipe extrusion machine

HDPE/PVC double wall corrugated pipe extrusion machine

2. Plastic Solid Pipe extrusion machine, Plastic Sheet extrusion machine, Plastic Profile extrusion machine

PVC UPVC CPVC pipe extrusion machine

HDPE gas and water pipe extrusion machine

PP pipe extrusion machine

PPR pipe extrusion machine

PVC hose extrusion machine

PVC sheet, PVC marble sheet, PVC foam sheet, PVC edge band sheet extrusion machine

PP PE PS HIPS sheet extrusion machine

PET sheet extrusion machine

PMMA sheet extrusion machine

PP hollow sheet/ corrugated sheet extrusion machine

UPVC window and door profile extrusion machine

PVC ceiling panel extrusion machine

3. Wood Plastic Composite WPC extrusion machine

WPC profile extrusion machine

WPC PVC foam board extrusion machine

WPC door board and door frame extrusion machine

Our machines has been exported to more than 40 countries in the world and built win-win business with our customers.

- Main Product

China

China