2205 duplex steel flange

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- 2205 duplex steel flange

- Payment Terms

- L/C,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Flanges

Dlh Special Material Co.,Ltd

- Verified Certificate

-

8

| Product name | 2205 duplex steel flange | Certification | - |

|---|---|---|---|

| Category | Flanges | Ingredients | - |

| Keyword | duplex2205 flange , s31803 flange , astm a812 f51 flanges , 1.4462 flange | Unit Size | - |

| Brand name | 2205 duplex steel flange | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

DUPLEX STEEL UNS S31803 FLANGES / A240 UNS S32205/S31803 / EURONORM: 1.4462 X2CrNiMoN 22.5.3 / AFNOR: Z3 CrNi 22.05 AZ / DIN: W.Nr 1.4462 :

GENERAL PROPERTIES:

Duplex 2205 is a two-phase, ferritic, austenitic 22% chromium, 3% molybdenum, 5 to 6% nickel alloyed stainless steel. It is the most widely used duplex stainless steel grade and is characterized by high yield strength, double that of the standard austenitic stainless steel grades. It also demonstrates good fatigue strength, as well as outstanding resistance to stress corrosion cracking, crevice, pitting, erosion, and general corrosion in severe environments.

APPLICATION:

- Chemical processing, transport and storage – pressure vessels, tanks, piping, and heat exchangers

- Oil and gas exploration and processing equipment – piping, tubing, and heat exchangers

- Marine and other high chloride environments

- Effluent scrubbing systems

- Pulp and paper industry – digesters, bleaching equipment, and stock-handling systems

- Cargo tanks for ships and trucks

- Food processing equipment

- Biofuels plants

COROSSION RESISTANCE:

- Due to its high chromium, molybdenum, and nitrogen content, Duplex 2205 demonstrates superior corrosion resistant properties to 316 and 316L in most environments

- Chromium, molybdenum, and nitrogen content also provide high resistance to pitting and crevice corrosion, even in oxidizing and acidic solutions

- Resistant to chloride stress corrosion cracking and temperatures of up to about 302°F (150°C)

- The presence of ferrite provides for good performance of Duplex 2205 in caustic environments

HEAT RESISTANCE:

- Similar to other duplex stainless steels, Duplex 2205 has good oxidation resistance at high temperatures

- Subject to embrittlement when exposed to temperatures above 572°F (300°C) even when exposed for short periods of time; Duplex 2205 is therefore not recommended for use above 572°F (300°C)

WELDING CHARACTERISTICS:

- Possesses good weldability

- Should not generally be welded without filler metal as this may result in excessive ferrite

HEAT TREATMENT:

- Annealing temperature range is 1868 to 2012°F (1020 to 1100°C)

- Cannot be hardened by heat treatment – but Duplex 2205 does work-harden

- Special consideration is needed to compensate for a higher coefficient of thermal expansion to avoid warping and distortion

PROCESSING - HOT FORMING:

Most Duplex 2205 producers recommend a maximum hot forming temperature between 2010 and 2100°F (1100 to 1150°C). If the shape of the work piece is not compact, the edges may be significantly cooler than the bulk, and there is risk of cracking in the cooler regions.

PROCESSING - COLD FORMING:

Duplex 2205 has shown good formability in a variety of fabrications. The high strength of Duplex 2205 can pose problems. Even when the equipment has sufficient power, allowance must be made for higher spring-back caused by the grade’s high strength.

MACHINABILITY:

Duplex 2205 is somewhat more difficult to machine than the 300 series austenitic stainless steels. Higher cutting forces are required and more rapid tool wear is typical. Some guidelines for machining are: A) Use powerful, rigid machines with extremely strong rigid mounting of tools and work piece, B) Minimize vibration by keeping the tool extension as short as possible, C) Use a nose radius on the tool, no longer than necessary, for carbides that have a sharp edge while still providing adequate strength, D) Design machining sequences to always provide for a depth of cut below the work hardened layer resulting from the previous passes.

CHEMICAL PROPERTIES:

| C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|

| 2205 (S31803) |

0.03 max |

2.0 max |

1.0 max |

0.03 max |

0.02 max |

min: 21.0 max: 23.0 |

min: 2.5 max: 3.5 |

min: 4.5 max: 6.5 |

min: 0.08 max: 0.20 |

| 2205 (S32205) |

0.03 max |

2.0 max |

1.0 max |

0.03 max |

0.02 max |

min: 22.0 max: 23.0 |

min: 3.0 max: 3.5 |

min: 4.5 max: 6.5 |

min: 0.14 max: 0.20 |

MECHANICAL PROPERTIES:

| Grade | Tensile Strength ksi (min) |

Yield Strength 0.2% ksi (min) |

Elongation % | Hardness (HB) MAX |

|---|---|---|---|---|

| 2205 | 90 | 65 | 25 | 217 |

PHYSICAL PROPERTIES:

| Density lbm/in3 |

Electrical Resistivity mW•in |

Thermal Conductivity (BTU/hr•ft•°F) |

Heat Capacity BTU/lbm•°F |

Electrical Resistivity (in x 10-6) |

|

|---|---|---|---|---|---|

| at 68°F | 0.278 | 27.6 | 8.7 | 0.112 | 33.5 |

| at 212°F | 26.1 | 9.2 | 0.119 | 35.4 | |

| at 392°F | 25.4 | 9.8 | 0.127 | 37.4 | |

| at 572°F | 24.9 | 10.4 | 0.134 | 39.4 |

| ASME/ANSI B16.5 | Welding Neck Flange, Slipon Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Ring Type Joint Flange |

|---|---|

| Pressure Class | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B16.47 | Welding Neck Flange, Blind Flange (Series A & B) |

| Pressure Class | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | (Orifice Flanges) Welding Neck Flange, Slipon Flange, Threaded Flange |

| Pressure Class | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Welding Flange (111/134), Hubbed Slipon Flange (112), Hubbed Threaded Flange (113), Lapped Pipe End Flange (133), Plate Flange (101), Loose Plate Flange (102), Loose Plate with Weld-neck Flange (104), Blank Flange (105) |

| Pressure Class | PN 2.5 to PN 100 |

| Din Flanges | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673 |

| Pressure Class | PN 6 to PN 100 |

| ANFOr NFE 29-230 | Plate Flange (01), loose Plate Flange (02, 03, 04), Blind Flange (05), Welding Neck flange (11), Hubbed Slip on Flange (12), Screwed Flange (13),Hubbed Socket Welding Flange (14), Loose Hubbed Flange (15) Integral Flange (21) |

| Pressure Class | Iso - PN 2.5 to PN 40 |

| Pr EN 1092-1 Flanges | Plate Flange (01), Loose Plate Flange (02, 04), Blind Flange (05), Welding Neck Flange (11), Hubbed Slip on flange (12), Screwed Flange (13), Integral Flange (21) |

| Pressure Class | PN 2.5 to PN 100 |

| ASME/ANSI B 16.9/MSS SP-4 | Stub End |

| Type | A, B, C |

| Metal | Grade | UNS Number |

|---|---|---|

| Austenitic / Ferritic / Austenitic / Stainless Steel | F304 / F304H / F304L * |

S30400 / S30409 / S30403 S30900 S31000 / S31009 S31600 / S31609 / S31603 S31700 / S31703 S32100 / S32109 S34700 / S34709 S31803 / S32205 S32750 S44600 |

| Ferritic / Martensitic Alloys | F1* |

K12822 K41545 / K42544 S41000 K90941 K11597 / K11572 K21590 K90901 K11564 |

| Nickel & Nickel Based Alloys | Nickel 200* Nickel 201* Alloy 400* Alloy 600* Alloy 601 Alloy 625 Alloy 800 / 800H / 800HT* Alloy 825* Alloy 904L* Alloy 20* Alloy C276* |

N02200 N02201 N04400 N06600 N06601 N06625 N08800 / N08810 / N08811 N08825 N08904 N08020 N10276 |

| Low Temperature Alloys | LF - 1* LF - 2* LF - 3* A707 L3* A694 F42 - F65* A350 LF6* |

K03009 |

| Aluminum Alloys | Alum 3003*

Alum 6061 |

A93003

A96061 |

| Copper - Nickel Alloys | 70/30 90/10 |

C71500 C70600 |

| ASTM | 304/304L/304H, 316/316L/316H, 317/317L, 321/321H, 347/347H, 316Ti, F51 |

|---|---|

| DIN | WNR 1.4541, WNR 1.4571, WNR 1.4301, WNR 1.4306, WNR 1.4307, WNR 1.4401, WNR 1.4404, WNR 1.4438, WNR 1.4462 |

| AFNOR (NF E) | BF Z 3 CN 19-09, BF Z 7 CN 18-09, BF Z 6 CNT 18-10, BF Z 3 CND 17-11-02, BF Z 7 CND 17-11-02, BF Z 6 CNDT 17-12, BF Z 6 CNDNb 18-12 |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T,Western Union | Shipping time | Negotiable |

- President

- Alex Lane

- Address

- No.308 Jinxuan Road, Jianghai Economic Park Area

- Product Category

- Flanges

- Year Established

- 1969

- Company introduction

-

Now,pick up your phone to call us (86-17306930653) or send an email to us(dlhsm@foxmail.com).

Welcome to Dlh Special Material Co.,Ltd,looking for special metal products? Is there a brand or alloy that you cannot find? Ask us.

We are a high and new technology enterprise specializing in research, developing and manufacturing of various special alloys and hard-to-find metal materials, such as duplex stainless steel,hastelloy,incoloy,inconel,invar,monel,nickel alloys,cobalt alloys,copper alloys,titanium alloys,etc.used for the difficult jobs in engineering. These alloys are highly engineered to offer a superior combination of heat resistance, high-temperature corrosion resistance, toughness and strength and are used in the world's most technically demanding industries and applications.

We are active in the special metal market many years and therefore have extensive partnerships with reputable mills,well-connected with these mills, we can supply almost all types of products you need and can get it fast including plate/sheet/strip,pipe/tube,round/Hex/Flat bar,welding wire/rod,pipe fittings,flanges,forgings,fasteners,etc.

We can meet most ASME,ASTM,AMS,and military specifications and can cross-reference to most international standards,including full EN10204 3.1 certificate.

Our advantages below help us establish long-term cooperation with customers throughout the world.

1.A Single Source,One-stop Service.

2.Small orders accepted.

3.Inventory a lot of plates,bars,wire,etc.

4.Custom made accepted.

5.Quick reply,fast shipment.

6.Strong Technical Support.

7. Professional Sales Team.

8.Provide solution to hard-to-find materials.

The DLH Team is looking forward to handle all your inquiries and questions.

Now,pick up your phone to call us (86-17306930653) or send an email to us(dlhsm@foxmail.com).

- Main Product

Related Products

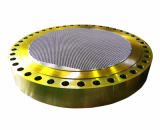

TUBE SHEET

Flange

1/2" Feeder/LDF Cable

Copper/ Copper alloy pipe, fittings, flanges and stainless fittings, flanges and Nipples

Orifice Flange

China

China