PP corrugated hollow sheet extrusion machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Tongsan

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Plastic Product Making Machinery

Qingdao Tongsan Plastic Machinery Co.,ltd

- Verified Certificate

-

8

| Product name | PP corrugated hollow sheet extrusion machine | Certification | - |

|---|---|---|---|

| Category | Plastic Product Making Machinery | Ingredients | - |

| Keyword | extruder , machine , sheet , hollow | Unit Size | - |

| Brand name | Tongsan | Unit Weigh | 15000 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

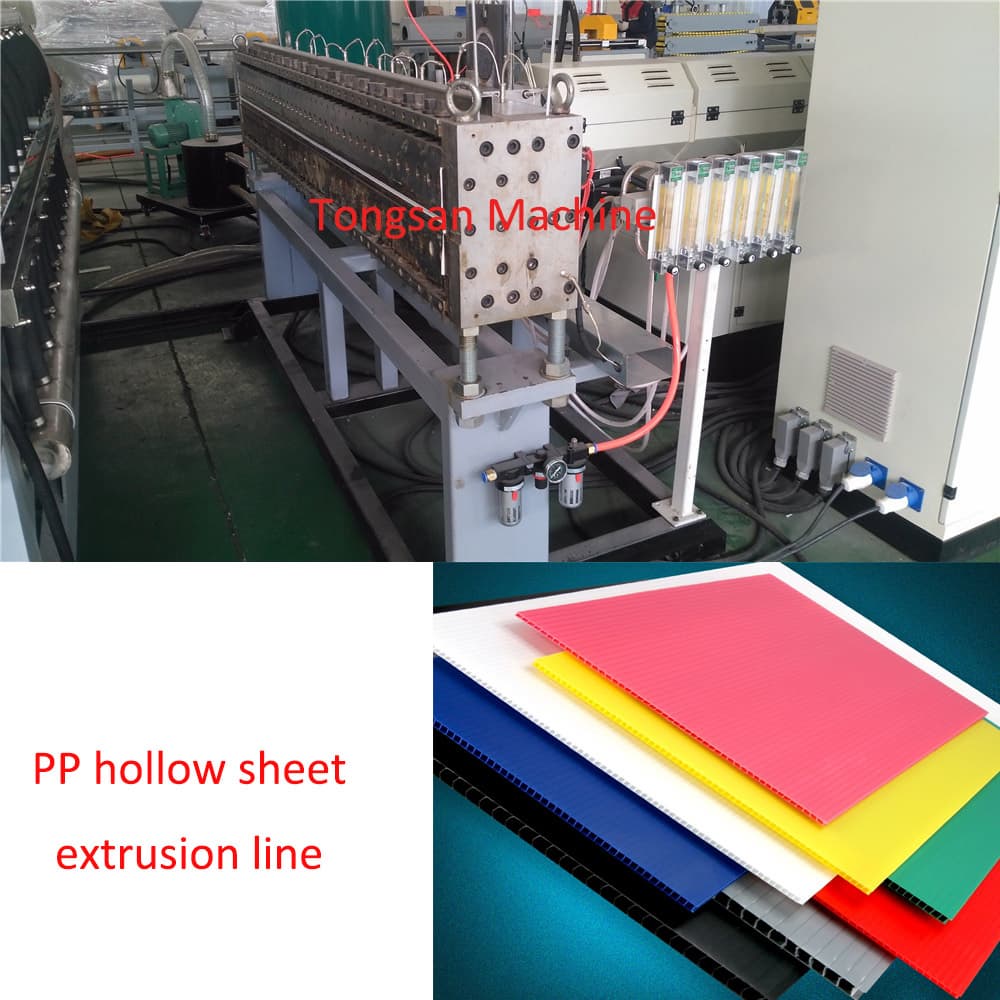

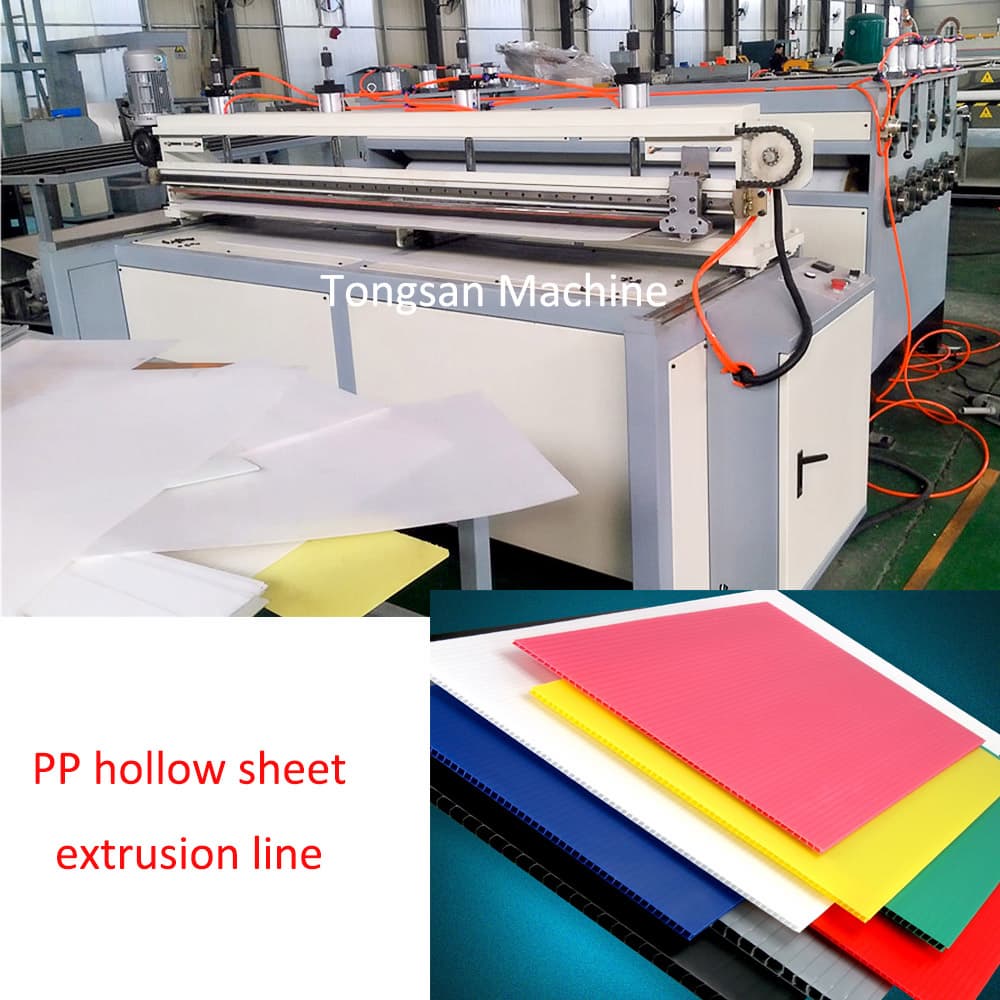

PP hollow sheet making machine, PP hollow sheet extrusion machine, PP corrugated sheet making machine, PP corrugated sheet extruder

1. Introduction of the PP PE hollow sheet extruder machine

PE/PP hollow grid plate is an ideal substitute for paper box in making packaging box. It is characterized by light weight, high intensity, dampproof, and anticorrosion. The width of the products is 1220-2100mm, and the thickness is 2mm-12mm.

2. Consists and Features of the PP PE hollow sheet extrusion machine

Extruder:The specially designed screw and the advanced controlling system ensure excellent plasticization, high output and stable extruding.

Screen changer:Quick screen changer of hydraulic system ensures the short course of screen changing. Double-position combined with special sealing structure guarantee stable operation of screen changer.

Mould:Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips, and also differential action of up-down piece guarantee even thickness of the plate.

Vacuum calibrating table:Heating exchanging and cooling system of quick speed in calibrating system alternate effectively and ordinally with vacuum system, which ensures calibrating precision. Vacuum system composes two independent subsystems and each is equipped with several fixed circulating vacuum lines of three-point type. Meanwhile, each line carries vacuum regulating system and vacuum display system that realize even and stable vacuum degree of plate surface.

Hauling off machine:There are two tractors. The first one is high power, high reduction ratio, multi-roller type, well low-speed operation, high traction and is able to draw the plate up from the calibrating table evenly and synchronal. The second one is designed to remove stress, and in addition it is equipped with edge-cutting device to ensure the valid width and smooth cut of the edges.

Anneal oven:The advanced large area conductive heating mode can effectively remove the stress of plate and further improve planeness of the plate.

Cutting machine:Accurate instant length-fixed cutting and automatic up-down discharging system combined with alloy steel sharp blade realize high quality of cutting.

3. Samples and application of the PP hollow sheet

Polypropylene hollow sheet(PP hollow sheet) is one of the packaging material which is most flexibility and widely used.

The main component of the PP hollow plate is polypropylene, which is a highly pure hydrocarbon, non-toxic, anti-chemical, combustible, no hazardous substances and environment friendly.

In addition to paper products, Tri-Wall also has our own PP hollow board production line for providing the best packaging solution according to different situations.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Mr.Li

- Address

- West of Yangzhou Road, Jiaozhou

- Product Category

- Plastic Product Making Machinery

- Year Established

- 1997

- No. of Total Employees

- 51-100

- Company introduction

-

<p>

Qingdao Tongsan Plastic Machinery Co.,ltd is an Chinese plastic extruder and plastic extrusion line and plastic recycling machine manufacturer.

Our factory was founded in 1997, since foundation, we focused on the plastic extrusion machine Research and development, we always do our best to improved our machine quality and service level.

With more than 20 years’ development, we have built our features and profession in the plastic extrusion machine field.

1. Plastic corrugated pipe extrusion machine

pp pe pvc single wall corrugated pipe extrusion machine

high speed single wall corrugated pipe extrusion machine

HDPE/PVC double wall corrugated pipe extrusion machine

2. Plastic Solid Pipe extrusion machine, Plastic Sheet extrusion machine, Plastic Profile extrusion machine

PVC UPVC CPVC pipe extrusion machine

HDPE gas and water pipe extrusion machine

PP pipe extrusion machine

PPR pipe extrusion machine

PVC hose extrusion machine

PVC sheet, PVC marble sheet, PVC foam sheet, PVC edge band sheet extrusion machine

PP PE PS HIPS sheet extrusion machine

PET sheet extrusion machine

PMMA sheet extrusion machine

PP hollow sheet/ corrugated sheet extrusion machine

UPVC window and door profile extrusion machine

PVC ceiling panel extrusion machine

3. Wood Plastic Composite WPC extrusion machine

WPC profile extrusion machine

WPC PVC foam board extrusion machine

WPC door board and door frame extrusion machine

Our machines has been exported to more than 40 countries in the world and built win-win business with our customers.

- Main Product

Related Products

PVC decorative film

PE Foam Sheet Extrusion Line JINSUNG

Medical dental saliva ejector tube making machine

RUBBER GRIP MOLD

PLASTIC PEN MOLD IN STOCK (BRAND NEW)

China

China