Waste oil recycling distillation plant

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- DOING

- Payment Terms

- D/A,D/P,L/C,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Recycling

DoingGroup

- Verified Certificate

-

8

| Product name | Waste oil recycling distillation plant | Certification | - |

|---|---|---|---|

| Category | Recycling | Ingredients | - |

| Keyword | oil recycling plant , waste oil to diesel , distilaltion plant , distillaiton plant | Unit Size | - |

| Brand name | DOING | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Waste oil recycling distillation plant

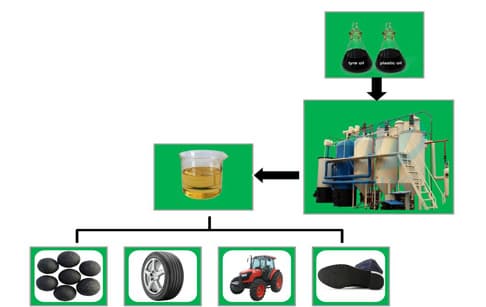

Waste oil recycling distillation plant is project of Doing group use the sludge,waste engine oil, tyre pyrolysis oil,plastic pyrolysis oil, sump oil as raw material, use the special distillation and refining technology to get oil. Waste Oil Distillation Plant can make the oil yield reach as high as 80%-90%. Doing company is in the leading level in machinery, technology. marketing, research and development.www(dot)wastetireoil(dot)com

Waste oil recycling distillation plant is self-shunt vacuum distillation unit, distillation system uses a tube furnace (independent research) heating the continuous distillation process under negative pressure to be waste oil distillation.Because the waste oil contains large amounts of water so we should dehydration before distillation.For example, the raw material ( like used engine oil) recovery is more than 90% when the water percentage is less than 5%.www(dot)wastetireoil(dot)com

Waste oil recycling distillation plant can be used for refining waste oil, waste engine oil, sludge, pyrolysis oil (tyre pyrolysis oil and plastic pyrolysis oil) and sump oil into qualified diesel fuel. And the diesel oil can be directly used in low speed engines and generators

Diesel fuel oil application

In the process of waste oil recycling distillation plant,The cold materials (waste oil) should be pre-heat exchanger with the overhead vapor phase component first.Materials after heat exchange into the falling film evaporator using secondary heating flue gas dehydration,and then through the tube furnace heating again after after the temperature meet the process requirements into ectification within the column Control reflux ratio at the same time, On the top of the gas phase components after heat exchange with the raw condensation receiving tank into the light components, To restructuring after restructuring of condensing tank,Tank bottom components into the slag,Non-condensable gas back into the tube furnace combustion after water seal.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,T/T,Western Union | Shipping time | Negotiable |

- President

- Bonnie

- Address

- No.138 Yingxie Road,Jinshui District,Zhengzhou, Henan Province, China

- Product Category

- Crude Oil,Other Metal & Metallurgy Machinery,Waste Management

- Year Established

- 1976

- No. of Total Employees

- 101-500

- Company introduction

-

Henan Doing Mechanical Equipment Co., Ltd is a comprehensive enterprise related to manufacture, marketing, installation and after sale service etc.

The company is committed to developing and manufacturing of all kinds of large scale and small acale equipment. It won leading position and good reputation with its high quality products and professional service.

The main products: scrap cable wire recycling machine. PCB (Printed Circuit Board ) recycling machine. Aluminum and plastic composition recycling machine. Home electric applaince recycling machine, etc.

waste tire and plastic recycling machine with relavent equipements, like tire cutter, carbon black briquette machine and carbon black grinding mill etc;

waste engine oil, waste tire and plastic oil refinery machine and relavent euipments, like oil filter etc;

Our machinery have been sold to Italy, Romania, Macedonia, Albania, Estonia, Rusia, Egypt, Ethopia, Nigeria, Congo, Lebanon, Jordan, Iran, Pakistan, Kazakhstan, India, Tailand, Malaysia, Mexico, Panama, Guatemala, Aruba, Jamaica, Ecuador, Haiti etc.

Company has won good reputation with its advanced production technology, professional installation and after-sales service.

Welcome your visit!

- Main Product

Related Products

100% PCR Stretch Film

Battery Regeneration System

aqsiq license

100% Organic Eco-Friendly Renewable Coir Cocopeat 30kg bag

Battery Regeneration System

China

China