Arselon flame retardant staple fiber

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Belarus

- Brand name

- ARSELON

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- aramid fiber, nonwoven cloth, spun yarn, staple fiber

- Category

- Nonwoven Fabric , Other Fiber , Threads , Other Firefighting Equipment

OJSC SvetlogorskKhimvolokno

- Verified Certificate

-

7

| Product name | Arselon flame retardant staple fiber | Certification | - |

|---|---|---|---|

| Category |

Nonwoven Fabric

Other Fiber Threads Other Firefighting Equipment |

Ingredients | - |

| Keyword | aramid fiber , nonwoven cloth , spun yarn , staple fiber | Unit Size | 0.6 * 1.1 * 1.35 m |

| Brand name | ARSELON | Unit Weigh | 250 kg |

| origin | Belarus | Stock | - |

| Supply type | - | HS code | 55 |

Product Information

ARSELON® is an inherently flame-resistant,

high-temperature resistant fiber that will not melt, drip, or support

combustion in air. It is offered in

yarn, felt, fabric, paper and fiber forms.

ARSELON® is heat- and flame-resistant poly-oxa-diazole

(POD) FIBER includes a range of fabrics, fibers, and nonwovens to play a vital

role in making automobiles and aircraft faster and safer, as well as protecting

workers, emergency response personnel, buildings, our environment and work.

PROPERTIES

Heat resistance.

Thermal destruction of Arselon begins at 505ºC (941ºF),

working temperature in ambient air: from cryogenic conditions and up to +400ºC

(752ºF). Arselon’s durability stays within 3 years at +300ºC (572ºF).

Low inflammability.

Arselon withstands the exposure of open fire, does not

melt. Oxygen index LOI is 30%. Arselon fabric can resist to high-heated

(600-700ºC // 1112-1292ºF) sparks and molten metal splatters.

Low shrinkage.

At high temperature (up to 450ºC // 842ºF) linear

shrinkage is max 0.5 %.

Chemical resistance.

Arselon fiber has high resistance to organic solvents

and acids. Material keeps stable to diluted inorganic acids and alkalis at 100ºC

(212ºF).

Humidity.

Humidity of Arselon can be compared to viscose and

cotton (10-11%).

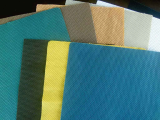

PRODUCT LINE

|

STAPLE FIBER |

Staple fiber: linear density – 0.17 tex / 0.22 tex / 0.33 tex cutting length – 36 mm / 51 mm / 66 mm both UV-Stabilized and non UV-Stabilized are available

Goes perfectly into: - industries

from asphalt and cement plants to chemical and steel factories use filter

media made of Arselon fiber (100% Arselon or mixed with other fibers) - heat resistant spun yarn and fabric out of it

(protective apparel, FR flooring, home and office textile) - POD paper for electro-insulation, printed circuit

boards |

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- V. V. Kostyukevich

- Address

- Zavodskaya 5, 247439, Svetlogorsk, Republic of Belarus

- Product Category

- Fabric,Fiber,Other Fiber,Other Yarn,Threads

- Year Established

- 1964

- No. of Total Employees

- over 2000

- Company introduction

-

We are SOHIM Company.We stay in Belarus and have more than 35 years of experience at producing:- POD flame retardant filament yarns called ARSELON- Carbon Rayon based materialsARSELON® is an inherently flame-resistant, high-temperature resistant fiber that will not melt, drip, or support combustion in air. It is offered in yarn, felt, fabric, paper and fiber forms.ARSELON® is heat- and flame-resistant poly-oxa-diazole (POD) FIBER includes a range of fabrics, fibers, and nonwovens to play a vital role in making automobiles and aircraft faster and safer, as well as protecting workers, emergency response personnel, buildings, our environment and work.Our manufacturing units operate primarily in the areas of processing technical rayon fiber into different types of carbon yarns, felts, fabrics, ribbons etc.

Our carbon fiber has a number of advantages which mostly came out from initial raw material – rayon industrial yarn:

§ - stable mechanical properties during temperature and load treatments (including tribological and antifriction properties)

§ - heat resistance and low thermal conductivity (high-temperature applications)

§ - excellent electro conductive properties (heating applications)

§ - high absorption capacity (filters, medical sorbents, supercapacitors)

§ - chemical resistance (corrosion protection)

§ - biocompatibility (medical applications)

§ - electromagnetic rays shielding (shielding panels, cloth, units etc)

We do our carbon materials in 2 ways: graphitized (treated at 2200°C // 3992°F) and activated.

- Main Markets

-

Canada

Canada

China

China

Czecho Republic

Czecho Republic

France

France

Germany

Germany

Hong Kong(China)

Hong Kong(China)

Russia

Russia

South Korea

South Korea

Taiwan

Taiwan

- Main Product

Related Products

Photoluminescent yarns/luminescent yarn/glow yarns

Nylon Cambrelle Lining Manufacturer in China!

_Clean_agent_Fire_Extinguishing_System_2.jpg)

FM-200(HFC-227ea) Clean agent Fire Extinguishing System

Air Filter Media

Raw Wool

Belarus

Belarus