Alumina Ceramic Tile for Wear Protection

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- sinho.com

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Ceramic Fiber

Shandong Sinho Special Materials Co., Ltd

- Verified Certificate

-

7

| Product name | Alumina Ceramic Tile for Wear Protection | Certification | - |

|---|---|---|---|

| Category | Ceramic Fiber | Ingredients | - |

| Keyword | ceramic wear plate , weldable tiles , alumina tile , alumina ceramic tiles | Unit Size | - |

| Brand name | sinho.com | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

SHC-Z Paste Ceramic

Low cost, and the best choice for pneumatic conveying below 300℃

We use a high temperature resistant inorganic adhesive to bond the wear resistant ceramic pieces on the device. Now it is widely used, because of with its convenient and fast installation.

Optional material

Ceramic: SHC wear resistant ceramic /SHN Nano ceramic

Viscose: SHV-200/SHV-300

Using temperature

Below 300℃

Suitable medium

Solid powder particles such as coal, limestone, clinker, cement slurry, such as ash, slag, gypsum, limestone etc.

Application

It is suitable for powder conveying or powder milling system, and it can also be used in slurry pipeline, such as coal powder pipe, powder selecting machine, separator, cyclone tube etc.

Regular size

Thickness 2/5/7/10/15mm

Super wear resistant

Vivtorinox hardness is up to 1800. Used for the powder delivery, and its wear resistance is 20 times than the ordinary carbon steel;

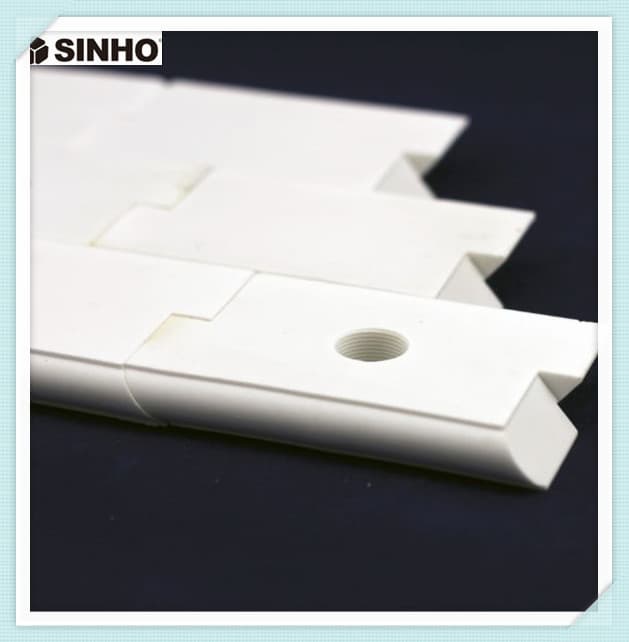

SHC-H Welding Ceramic

Special for pneumatic conveying system at high temperature

SHC-H Welding ceramic solve anti abrasion of pneumatic conveying system at high temperature introduced from German. The wear resistant ceramic is welded on the inner wall of the equipment to form a strong anti abrasion layer.

Optional material

Ceramic: SHC wear resistant ceramic /SHN Nano ceramic

Viscose: SHV-800

Using temperature

300℃ -800℃

Suitable medium

Solid powder particles such as coal, limestone, clinker, cement slurry, such as ash, slag, gypsum, limestone etc.

Application

It is used for powder conveying or pulverizing system equipment at high temperature, such as wind tube of cement plant waste heat power generation, grate cooler outlet pipe, air pipe of iron & steel plant.

Regular size

Thickness 5/7/10/15mm

Super wear resistant

Vivtorinox hardness is up to 1800. For the powder delivery, wear resistance is 20 times than the ordinary carbon steel;

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Sales Manager

- Product Category

- Ceramic Fiber

- Year Established

- 2012

- No. of Total Employees

- 1-50

- Company introduction

-

<p>

Shandong Sinho Special Materials Co., Ltd. is a professional manufacturer dedicated to the development of the wear resistant materials and energy-saving technology, located in Linyi national high tech Development Zone. We supply the technology consulting, engineering design, equipment manufacturing, installation of equipment for the thermal power, steel, cement, coal, port, oil, chemical, metallurgical, machinery and other industries to achieve the company's energy consumption. SINHO is in the domestic leading position in ceramic toughening technology by introducing the core technology of ceramic metal composite and low nitrogen combustion from Japan or Germany. SINHO can also supply the complete sets of wear resistant equipment, such as: low NOx burners, wear-resistant pipe, cyclone, wear-resistant fan impeller, ceramic ball valve, wear-resistant chute, structural ceramics, and rubber ceramic coated roller.

We are looking forward to innovation and conquer difficulties for you.

- Main Product

Related Products

superwool 607 blanket

Ceramic Fiber Paper

Aluminum Silica Acupuncture Blanket

Refractory sound insulation paper materials

vacuum formed ceramic fiber board for high temperature furnace

China

China