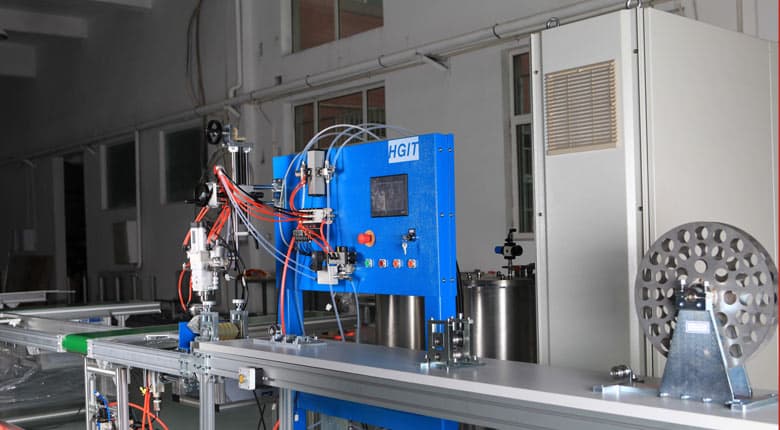

Aluminum cavity strip feeding foam machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- HGIT

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Machinery & Industry Equipment

Dalian Huagong Innovation Technology Co., Ltd.

- Verified Certificate

-

11

| Product name | Aluminum cavity strip feeding foam machine | Certification | - |

|---|---|---|---|

| Category | Other Machinery & Industry Equipment | Ingredients | - |

| Keyword | aluminum cavity strip feeding foam machine | Unit Size | - |

| Brand name | HGIT | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

A. Foaming technique may reduce energy consumption resulted from air circulation of barrier-strip heat insulation molding. Non-foamed K-value is 2.3 to 3.5, and the K-value of foamed profile can be lowered to 1.5 to 2.

B. Preventing siphonage effect: PA66GF25 heat insulating strip has certain water absorption. In winter, steam generated from air circulation inside profile cavity is absorbed by heat insulating strip, and brittle rupture will occur when coefficient of linear expansion reaches 30%. This will not happen to the profile after foaming, and PU foaming absorbs no water.

1、Stopping convection phenomenon in barrier-strip cavity, and improving heat-insulating performance of doors and windows.

Foaming technique may reduce energy consumption resulted from air circulation of barrier-strip heat insulation molding. Non-foamed K-value is 2.3 to 3.5, and the K-value of foamed profile can be lowered to 1.5 to 2.

2、 Preventing siphonage effect and seepage phenomenon resulted from the physical connection part between heat-insulating strip and metal.

PA66GF25 heat insulating strip has certain water absorption. In winter, steam generated from air circulation inside profile cavity is absorbed by heat insulating strip, and brittle rupture will occur when coefficient of linear expansion reaches 30%. This will not happen to the profile after foaming, and PU foaming absorbs no water.

3、Preventing shrinkage of heat-insulating strip that will break away from connection due to freeze expansion after hydrops inside thermal-insulation cavity.

4、Help to improve profile’s integral rigidity.

Effectively making up for the insufficient press-in in profile’s insertion process that leads to defective goods.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- Huagong

- Company introduction

-

Dalian Huagong Innovation Technology Co., Ltd was formally established in 2003, located in the beautiful coastal city-Dalian in China, which is an innovative and high technology industrial corporation gathering research and development, manufacturing, marketing and services.

The “Huagong HGIT” brand products of the company has passed ISO9001:2008 international quality system authentication and

won a number of national patents. Major products are: self-sealing automatic double surface gluer, heat insulation aluminum profile injecting production line (including aluminum profile potting machine, cutting bridge machine, gulleting machine and

two-tone compound machine), plates cementing and spreading device and customized automatic production line.

- Main Product

China

China

,_Smartphone_dryer,_heating_mobile_2.jpg)