brick-marble brick

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- marble brick

- Payment Terms

- L/C,Others,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- brick, marble, marble tile, paver

- Category

- Tiles & Accessories , Road Machinery , Bricks

bluemarble

- Verified Certificate

-

8

| Product name | brick-marble brick | Certification | - |

|---|---|---|---|

| Category |

Tiles & Accessories

Road Machinery Bricks |

Ingredients | - |

| Keyword | brick , marble , marble tile , paver | Unit Size | 75.0 * 230.0 * 90.0 mm |

| Brand name | marble brick | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | 6802 |

Product Information

Nobody is surprised at the longevity and durability of marble stone structures such as the Parthenon Temple at the Acropolis Square in Athens, built around the 5th century BCE in ancient Greece.

Thousands of year slater, it is the durability of markble that has enabled the passing down of structures such as Stonehenge, the Pyramids, and the Collisseum.

Compared to other construction materials, not only is stone significantly more durable, fire-resistant, and characterized by increased internal abrasive compression strength but also known for its external beauty and magnificence. As a result, it has been recognized the best possible structural and finishing material by humanity.

As marble is derived from nature and its color cannot be changed, the natural beauty of the stone and its natural aesthetics are easily apparent. With recent economic growth, stone has gained ground as a necessity instead of a luxury and grown into a trend, leading to increased use of natural stone in residential accommodation.

For a long time, humanity has used the relatively easier-to-procure and easier-to-use mud and cement bricks instead of stone to enhance the durability and fire-resistance of buildings.

While cement has become the most commonly used material in modern construction, it has also become a construction necessity because of its ease-of-use and strong durability.

As natural marble is the most natural construction material for humanity, natural marble bricks have combined the characteristics of both marble and the advantages of existing bricks to create an entirely new construction material by grafting together marble and cement for use in modern construction.

The company expressed hopes that natural marble bricks will launch a new revolution in construction history and will continue pursue continued development in the field of construction.

CEO, Blue Marble Inc.

-As a product created by joining natural marble with cement bricks, the entirely new natural marble bricks maintain the beautiful colors and natural texture of marble.

-As a new construction finishing material combining the characteristics of marble with the advantages of existing bricks, the bricks are environmentally friendly as they do not use any separate chemical adhesives when being combined with stone. The bricks are a new and globally competitive construction material with a registered Korean patent (patent number 10-146059) and international patent applications pending.

-As a result of three years of research and development, new production line equipment develop by the company's local subsidiary in China has been completed for use in a high-volume manufacturing system.

Advantages of marble bricks

Color patterns: allows for diverse color expression with over 200 types of natural marble colors

Surface finish: diverse marble surface finishes (polished, antique, corner, split, and dabbed)

Construction duration: as the structure and finish are completed simultaneously, all other finishing processes may be omitted

Construction costs: up to 50% cheaper than using stone in dry construction, 100% lower labor costs when compared with other finishes

Material costs: 30-50% cheaper than natural marble, 100% material cost savings when compared with other finishes

Dimensions: May be ordered in a range of dimensions outside of pre-established sizes

Design: diverse designs (logos, text, etc.) available for special order and use in construction

Construction methods: may be used without being divided up/advantageous for R-corner construction/advantageous in construction used to connect vertical materials

Marble brick structure and construction method

Aside from normal dimensions 75(W) * 230(L) * 90(T) // 120(W) * 300(L) * 90(T), special size orders are also welcome

All four sides of the bricks contain a gutter (an area for mortar replenishment) to allow for non-jointed (non-divided) construction.

The front and sides of corner stones are combined with marble to be advantageous in the construction of edges and corners.

The length of the back of the brick is shorter than the front to be advantageous in round construction.

Types of marble brick surface finish

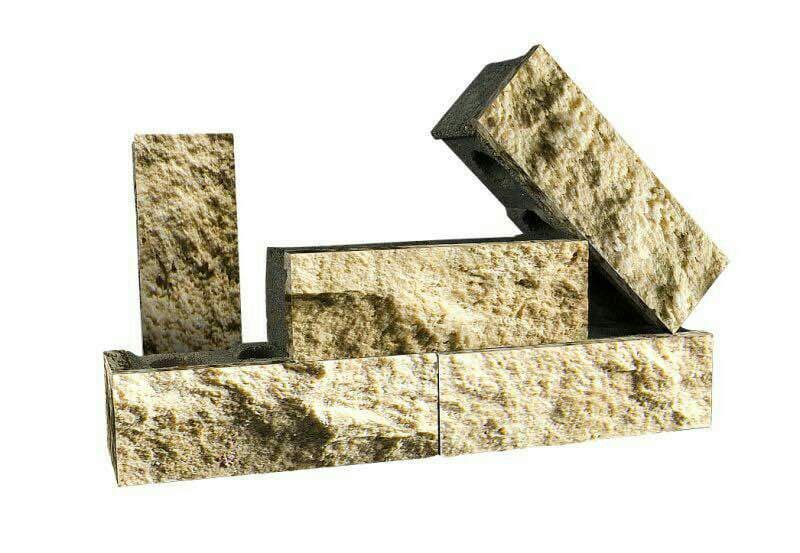

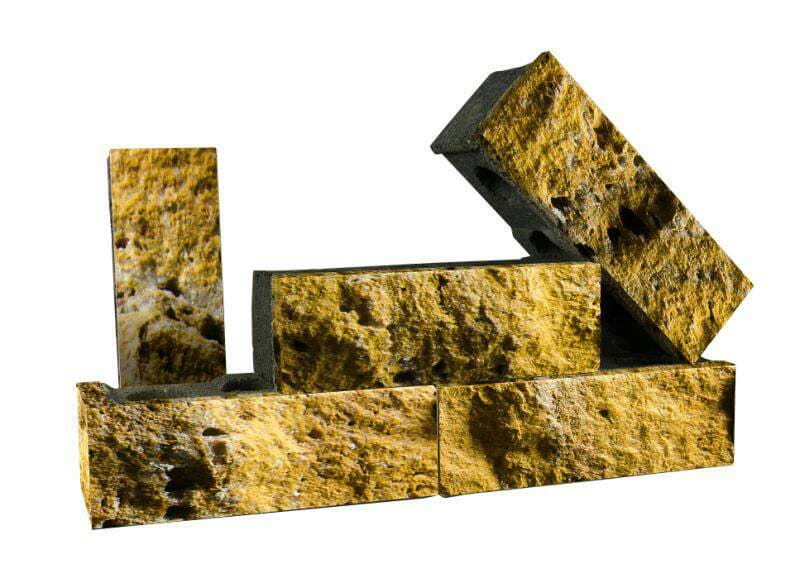

Antique corrosive finish

The surface of marble is corroded with acid (2-3mm unevenly) for a non-glossy antique look.

Used in normal brick joint construction with joints of 15-18mm

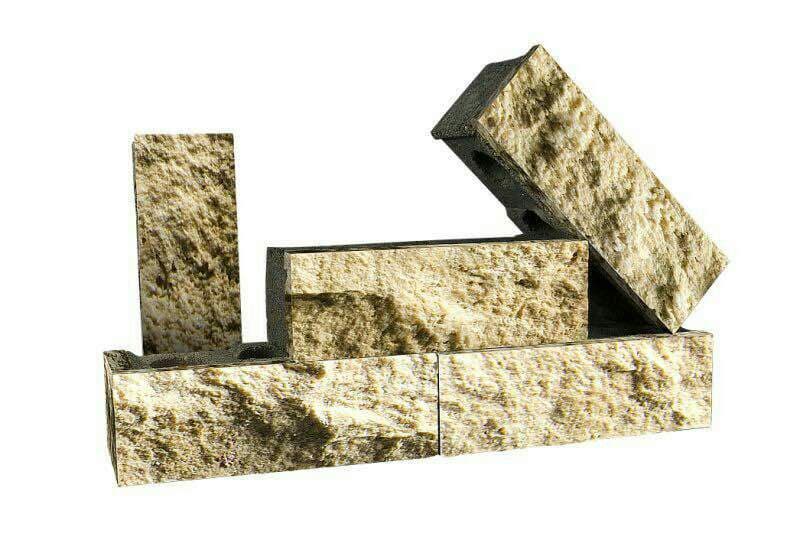

Chiseled edge removal finish

Approximately 15mm is removed from all four sides of the marble to give the stone a voluminous and imposing look.

Although vertical joints use normal brick joint construction, horizontal non-joint construction is possible

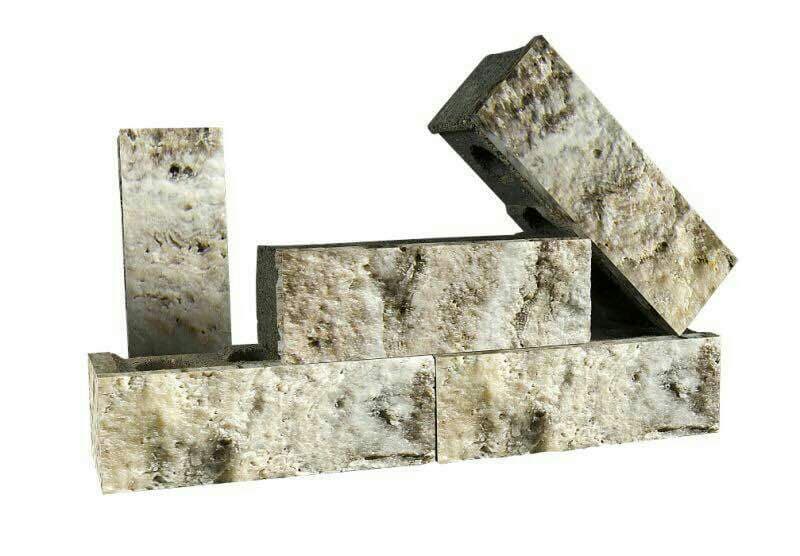

Natural split construction

The marble is split into two parts to express its natural beauty and coarse texture.

Has the advantage of non-joint construction for entire marble brick surfaces

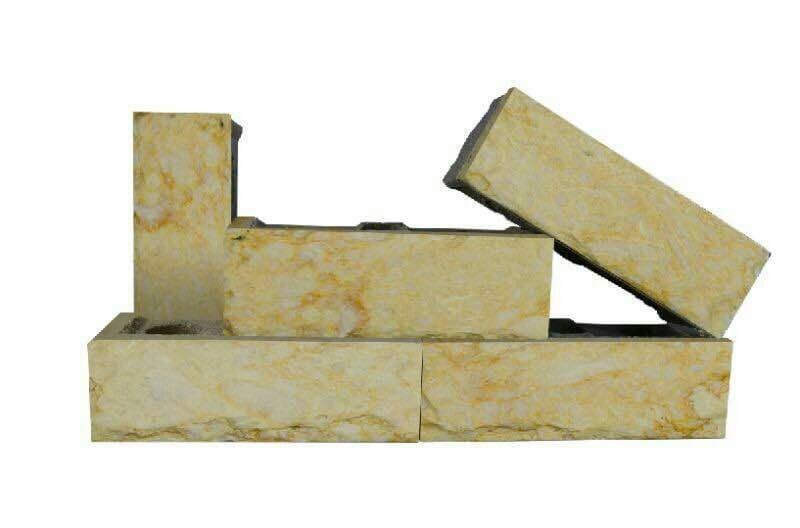

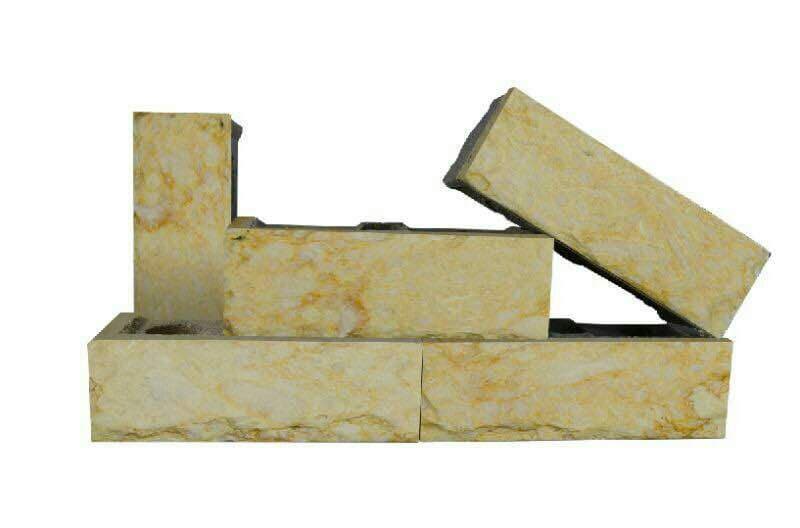

Polished: the surface of the stone is polished with water and whetstone for a natural shine for the most typical stone finish

Non-glossy treatment: after being polished, a non-glossy treatment prepares the brick for indoor use and blocks indirect light reflection

Sand blaster: the surface of the stone is sprayed with high pressure to create a rough texture for non-slip surfaces on bathroom floors

Flame treatment: the surface of the stone is exposed to more than 1500 degree heat momentarily for an even dusting of the surface of the stone to create a rough texture

Marble bricks

Compared to regular brick dimensions 75(W) * 230(L) * 90(T), the width has been reduced to 57 while the length has been significantly extended (L:470->600) in this new type of marble brick that maintains the structure, properties, colors, and construction methods used in bricks of regular dimensions, except that the surface of the marble has a thickness of more than 20mm.

If the vertical joint of the marble bricks (15-18mm) and the horizontal non-joint are used in construction, new designs impossible to create with existing bricks may be used. Another advantage is the significant decrease in construction costs.

Marble bricks break the mold of simple colors and standardization seen in existing bricks to create a new external expression featuring a European marble look.

- Product Info Attached File

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,Others,T/T | Shipping time | Negotiable |

- President

- yesoon park

- Address

- 7 sinchonnamro sujung-gu sungnamsi gyeonggi-do, korea

- Product Category

- Construction Material Making Machinery

- Year Established

- 2011

- No. of Total Employees

- 1-50

- Company introduction

-

Nobody is surprised at the longevity and durability of marble stone structures such as the Parthenon Temple at the Acropolis Square in Athens, built around the 5th century BCE in ancient Greece.

Thousands of year slater, it is the durability of markble that has enabled the passing down of structures such as Stonehenge, the Pyramids, and the Collisseum.

Compared to other construction materials, not only is stone significantly more durable, fire-resistant, and characterized by increased internal abrasive compression strength but also known for its external beauty and magnificence. As a result, it has been recognized the best possible structural and finishing material by humanity.

As marble is derived from nature and its color cannot be changed, the natural beauty of the stone and its natural aesthetics are easily apparent. With recent economic growth, stone has gained ground as a necessity instead of a luxury and grown into a trend, leading to increased use of natural stone in residential accommodation.

For a long time, humanity has used the relatively easier-to-procure and easier-to-use mud and cement bricks instead of stone to enhance the durability and fire-resistance of buildings.

While cement has become the most commonly used material in modern construction, it has also become a construction necessity because of its ease-of-use and strong durability.

As natural marble is the most natural construction material for humanity, natural marble bricks have combined the characteristics of both marble and the advantages of existing bricks to create an entirely new construction material by grafting together marble and cement for use in modern construction.

The company expressed hopes that natural marble bricks will launch a new revolution in construction history and will continue pursue continued development in the field of construction.

CEO, Blue Marble Inc.

- Main Markets

-

South Korea

South Korea

- Main Product

Related Products

VOLVO MOTOR GRADER SPARE PARTS

LVT - Loose Lay, PVC Flooring, Vinyl Tile

ClicknLoc

High Alumina Bricks

Taper Anti-Slanting Adjusting Roller Group for Belt Conveyor