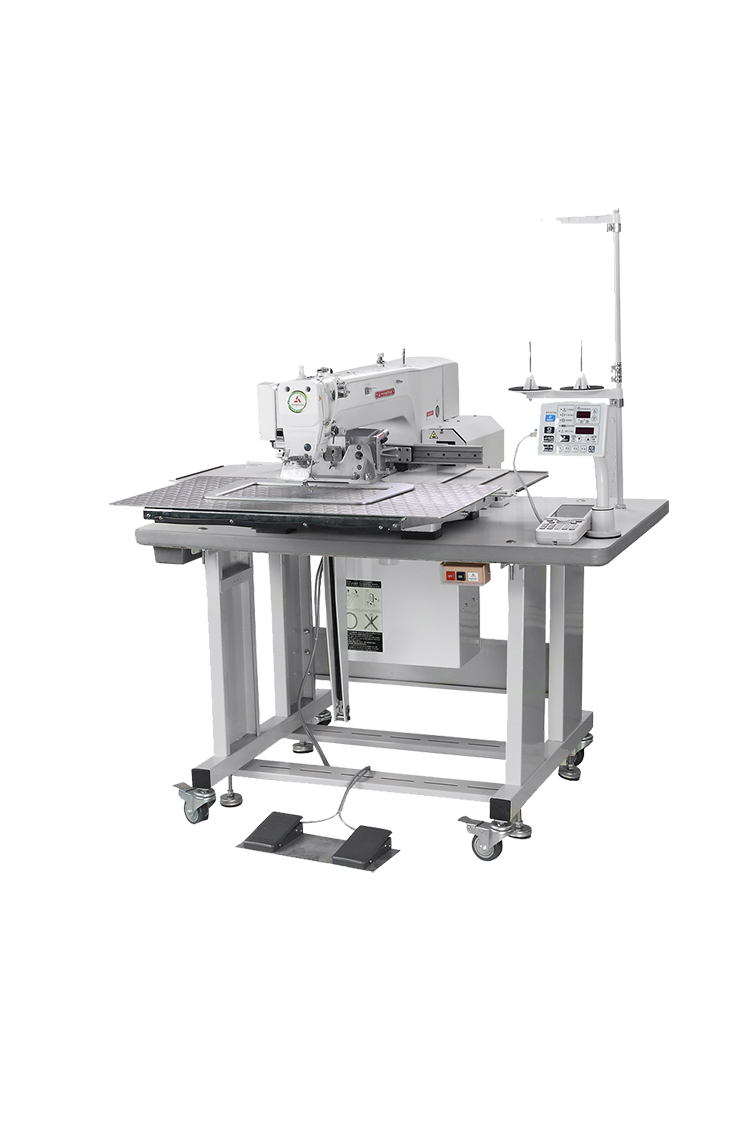

MLK-311G PROGRAMMER COMPUTERISED PATTERN SEWING MACHINE

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- ML

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- sewing machine, pattern sewing machine

Dongguan Mingling Industrial Automation Technology Co.,Ltd

- Verified Certificate

-

9

| Product name | MLK-311G PROGRAMMER COMPUTERISED PATTERN SEWING MACHINE | Certification | - |

|---|---|---|---|

| Category |

Other Machinery & Industry Equipment

Sewing Machines Other Apparel & Accessories Machinery |

Ingredients | - |

| Keyword | sewing machine , pattern sewing machine | Unit Size | - |

| Brand name | ML | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Fine stitchs,reliable floriation sewing

Maximum sewing speed 2700 neddle /min (using the 3.5mm stitch)

Powerful needle penetration force

And low power consumption, economic utility

Use a double stage clamp easily to locate the material

High-speed sewing and beautiful stitch, realizes the fastest sewing speed in the world, while energy saving achieve excellent sewing quality and production efficiency.

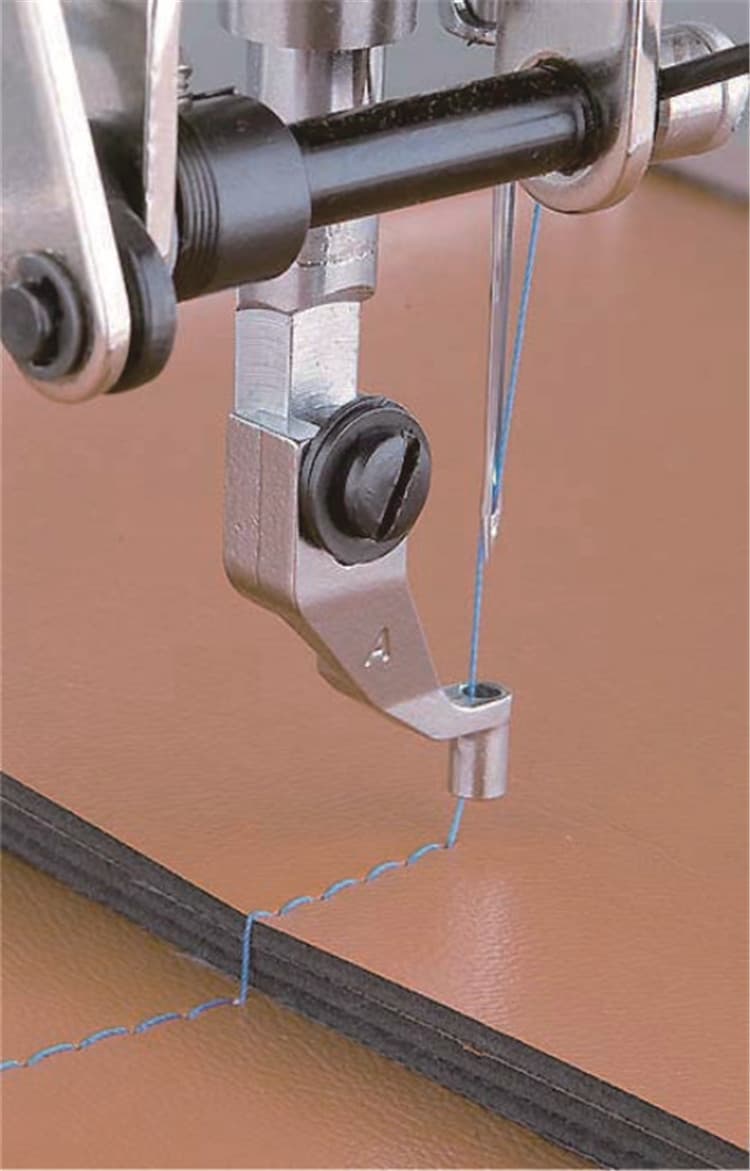

Beautiful stitch sewing

Because of falling needle accurately, equipment can sew fine parallel lines and positive

stitch. UseThe servo control and steel improved cloth feeding device, so you can sew a

high precision pattern, i.e.The high-speed sewing or sewing thick material, also won't

happened fine stitching, and aviod to bad stitchAnd deviation problem.

Highest sewing speed 2700stitches/min using stitch (3.5mm)

Achieved using 3.5mm stitch sewing 2700 / min high-speed sewing. Due to the adoption of the mingling

Corporation the original direct drive servo motor, starting / stopping reaction faster. Compared with the

traditional model of mechanical operation time shortened by about 28%, the production efficiency is improved.

Increased high penetration force

Compared with the traditional model, the use of servo motor more stronger than motor (550W).

Even in the low-speed sewing can get strong penetration force, and sewing to the thick materials can be successfully.

Low power consumption

Computer direct drive type mechanical system uses a motor with high efficiency and energy saving, can reduce the transmission process. Compared with the traditional model, the power consumption is reduced about 15% compared with the market similar sewing models, this equipment is the lowest power consumption of computer decoration, and realizes high-speed sewing and strong high speed sewing machine with high penetration force.

Easily and accurately positioning of cloth

Set a double step clamp, clamp can be stop and suspended in the middle position, and then down to the lowest point. Can set up a suitable height in the middle position, can quickly and accurately positioning the material. This can be reduce the extra operation caused by the positioning error of the sewing matter, saving the total cycle time during sewing.

Easily transformation of sewing pattern

Simple to change clamp

Remove the 4 screws to replaced clamp, also can be installed to the accurate position rapidly.

Accurate positioning in order to change the feed plate

According to the reference of the feeding plate to the bottom plate hole,the feeding plate easily

cna fix on the bottom plate, tighten the bolts to complete the installation. Accurate positioning of plate can be conveniently fix up.

Set to large capacity of memory

The sewing machine can be stored in the memory of large amounts of data (512 patterns, 500000 stitches *). Every time you can change pattern without reloading the sewing pattern. In addition, the CF card (Compact Flash) flash memory card with to the storage media, read and write speed, large amounts of data can be copied or transferred to other sewing machine or electric copy or transfer to other sewing machine or computer fo data management.

Environmental protection concept

Ming Ling company created "green label", carries on the classification to meet ISO14021 international industry standards and JIS Q14021 Japan industry standard products. MLK-342G meets this standard.These two models are environmental protection product, because "the use of direct drive system, achieve the industry's highest energy level", "the use of lead-free solder" and reduce the"packaging materials "and so on, is to protect the earth's environment sewing machine.

To realize low tension stable sewing

Servo control of high steel material feeding device, synchronization high degree of needle bar / take-up device, can be carried out under the condition of low tension of upper and bottom thread sewing.

The overlapping part eventhough in material, also can make the bottom thread tightness consistent.

Without tilting the machine head can be adjusted by driving a needle guard

No need to tilt the machine head, can be easily adjusted by driving needle guard.

No need to tilt the machine head, also can adjust machine between the needle and hook point.

Due to not installed presser foot arm support plate, so that a wide field of vision is clearly visible, also make the sewing inspection and fabric positioning also more simple.

Model | Flat Seam | 2-time hook | Sewing Area | Needle | Trimer | Thread wiper | Highest sewing speed | Air pressure |

MLK-311G | ★ | 2 | 130×100 | 0.05 - 12.7mm | ★ | ★ | 2,700 needles/min | 1.81 |

Model No. | MLK-311G | MLK-326G | MLK-342G | MLK-342GXL |

Machine head | Flat-seam floriation sewing machine(2-times hook) | |||

Line | Single-needle flat seam | |||

Highest sewing speed | 2,700 rmp* | 2,700 rmp* | 2,700 rmp* | 2,700 rmp* |

Sewing area (X*Y) | (MAX) 130X100mm | (MAX) 220X100mm | (MAX) 300X200mm | (MAX) 600X300mm |

Feeding material device |

| |||

Feeding material (servo motor) | ||||

Needle | 0.05 - 12.7mm | |||

Can be save by pin code | 500,000 needles*²Built--in memory can store 50000 stitches | |||

Each pattern highest sewing stitches | 2000(a pattern) | |||

Can be stored for sewing pattern | CF card built-in memory:512 species, 900 kinds | |||

| pneumatic | |||

Clamp drive | ||||

| (max) 30mm | |||

Clamp height | ||||

| One-piece presser foot | |||

Clamp lowest | ||||

| mm | |||

| 0.2-4.5mm or 4.5mm(factory Settings:3mm) | |||

Hook | Double hook (standard) | |||

Thread wiper divice | Standard equipment | |||

| Standard equipment | |||

Date memory | 2HD/1.44MB, 2DDFlash memory (can save with CF card) 3 inch disk 2HD/1.44BM.2DD | |||

Number of the user program | 50 | |||

Loop program number | 9 | |||

Motor | 750W Servomotor750w | |||

Weight | Head: about 160kg, Operating panel: about 0.6kg, Control box:14.2-16.2kg(Depending on the destination) | |||

Power | 220V,200V/220V/380V/400V 500VA | |||

Single phase 220v 3-phase 200v/380v/400v 500VA | ||||

Air pressure | 0.5Mpa 1.81/min | |||

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Lan Chen

- Address

- Hetian 2nd Industrial Zone,Houjie Town,Houjie Avenue,Dongguan City,Guangdong Province, China

- Product Category

- Other Apparel & Accessories Machinery,Other Machinery & Industry Equipment,Sewing Machines

- Year Established

- 2007

- No. of Total Employees

- 501-1000

- Company introduction

-

Ming Ling Industrial automation technology Co., LTD. Is engaged in computer pattern sewing machine the first domestic professional institutions.

The Ming hui quilted computer needle dealership was established in 1996, in 2000 focus on the marketing, research and development and manufacturing of the computer pattern sewing machine, has formed a research and development center, production, maintenance, marketing, customer service, and other elite departments, and set up headquarters in dongguan, zhongshan, guangzhou, shenzhen, Beijing, zhejiang, fujian, India, Vietnam, Hong Kong, Shanghai, jiangsu, shandong, hunan and other branches and agents, products are exported to Brazil, India, Vietnam, Iran, Turkey, Thailand, South Korea, Taiwan, Peru, Indonesia, more than 10 countries and regions such as Germany.

In 2006,Founded Zheng Nan (China) precision automation equipment Co., LTD., the main production and marketing its own brand name ling MLK - series computer sewing pattern,which is the only one in the same products for national sewing machine quality standards of product quality inspection center.We took the lead with sewing machine quality inspection center of China, China sewing machinery standardization committee, custom, the Chinese computer sewing machine national standard designs.And they are Has passed ISO9001:2008 international quality management system and CE certification, completely independent research and development of ling MLK - G control system with good quality, stable performance, high new technology and advanced service and reasonable price, won worldwide customers to favour.

In 2008 established Ming Ling (Hong Kong) international trading company, set up international marketing agency to enter the world market.

In 2010 Founded Ming Ling industrial automation technology co., LTD. in dongguan, comprehensive build global top sewing equipment.Company to "quality as the root, integrity-based" principle for customer service!

- Main Markets

-

Australia

Australia

Canada

Canada

Germany

Germany

Italy

Italy

Malaysia

Malaysia

North Korea

North Korea

South Korea

South Korea

Spain

Spain

U.S.A

U.S.A

Viet Nam

Viet Nam

- Main Product

Related Products

AIS3000 HD

3INCH POS RECEIPT PRINTER, Thermal Receipt Printer 80mm.

UIM2901-5A MACH3 break out board for CNC

12V Kiosk and Receipt thermal printer HMK054

Marine Loading Arm

China

China