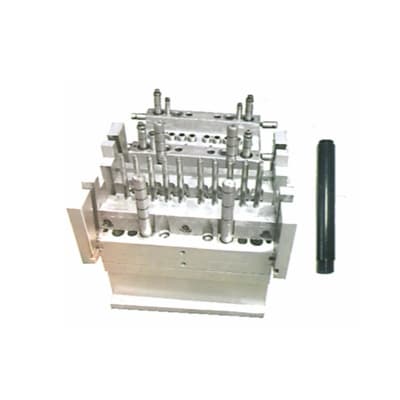

Plastic Pen Holder Injection Mold Making

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- EX Mould

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

EX Plastic Injection Mould Co.,Ltd

- Verified Certificate

-

9

| Product name | Plastic Pen Holder Injection Mold Making | Certification | - |

|---|---|---|---|

| Category |

Molds

Mould Design & Processing Services Plastic Product Making Machinery Mouldings |

Ingredients | - |

| Keyword | injection moulding , mouldings , plastic injection molding , plastic molding | Unit Size | - |

| Brand name | EX Mould | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 8479892070 |

Product Information

Plastic Pen Holder Injection Mold Making: Plastic Pen Holder Molder made of Hot Work Tool Steel, LKM Mold Base, Single Cavity, Polished surface.

Mold Service Life: 4,000,000 shots.

Mold Materials: Hot Work Tool Steel.

Product Material: SAN.

Runner: Cold Runner.

Mold Base: LKM.

Surface Finish Process: Polishing.

Cavity: Single Cavity.

Design Software: AutoCAD.

Shaping Mode: Injection Mold.

Application: used for manufacturing pen holder.

Certification: ISO9001: 2008.

Packing: Wooden Box.

After-sales Services: Experienced engineers will provide all-round

technical solutions to any problems occurred in customers mould

operation.

Origin: Shenzhen, Guangdong, China.

Package: General Exporting Packing.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Jeawin

- Address

- Room 101, No.126, Huangpu Road, Shajing, Shenzhen, Guangdong Province, China

- Product Category

- Molds,Mould Design & Processing Services,Plastic Product Making Machinery

- Year Established

- 2010

- No. of Total Employees

- 501-1000

- Company introduction

-

EX Plastic Injection Molding Company provides professional injection molding service include Tool Design & Build, High Speed CNC Machining, Wire EDM, Conventional EDM, Injection mold construction, Mold try-out, Mold refurbishing, repair,and maintenance, Machined components, Rework of existing components, Injection molding production.EX Plastic Injection Molding Company is ISO 9001 :2008 Compliant, which is the highest standard recognized in the Aerospace Industry. Our team of project managers, engineers, and support personnel are industry experts and committed to delivering the highest quality product with the most competitive price in the industry.

- Main Markets

-

Austria

Austria

Canada

Canada

France

France

Germany

Germany

Japan

Japan

Singapore

Singapore

South Korea

South Korea

U.S.A

U.S.A

- Main Product

Related Products

Plastic Sheet

chemical foam agent for leak stoppage

Plastic injection Mold for Automotive Lamp / Parts

Heavy Duty Pouch Laminator TOFO 330R6

keli szcx injection blow molding machine

China

China