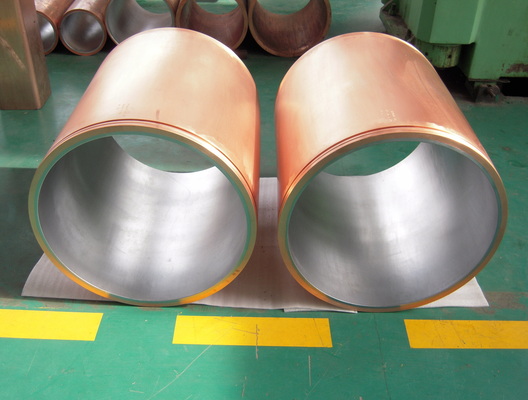

copper mould tube

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Copper Alloy & Profiles

LIAONING MINERAL & METALLURGY GROUP CO., LTD

- Verified Certificate

-

8

| Product name | copper mould tube | Certification | - |

|---|---|---|---|

| Category | Copper Alloy & Profiles | Ingredients | - |

| Keyword | copper mould tube , copper mould tube for ccm | Unit Size | 150.0 * 150.0 * 780.0 mm |

| Brand name | - | Unit Weigh | 50 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Office ADD: Room 403,D-5 building, Chuntianyuan,Ganjingzi District, Dalian-116000,China.

anna at lmmgroup.com.cn

Why work with us

1. No need to worry about quality,Get the same choice as the world famous Steel Mills

Regular supplier of the BAO STEEL and almost 40 steel plants all about the world.

2. Rapidly and professional no-replies-responsibility quotation.

Feel free to contact us on alibaba or send us Email.

3. No need to worried about trading with a fresh one.

With decades years export experience. multilingual service will be provide to our customers.

4.Trade assurance and Gold Supplier of Alibaba, You will get a more safety way to trade with us on alibaba.

5.Free Sample* will be provide to our new customers,

Also welcome you to come visit our factory or have a online Youtube view of our factory!

6.OEM service.

LMM Brand Copper Mould for continuous casting machine in steelmaking is available for :

billet caster, bloom caster, beam blank caster, slab/thin slab caster.

1. We supply high quality and durable copper mould tube with most competitive price and prompt delivery.

2. Our Copper Mould Tube meet ISO9001 standards,

high precision and meet hardness requirement, perfect taper and coated layer.

3. We have complete facilities to process every copper mould tube,galvanize plating,

hardness testing to provide accurate Chromium plating to the Mould Tubes to achieve high performance in heat resistance.

4. We manufacture thousands pieces of copper mould tube every month

and supply to several biggest Steel Group in China

which proved that our product is most trusted and satisfy by our customers.

LMM Mould's key features:

· 100% high quality Chile originated Copper;

· CuDHP, CuAg0.1, CuCrZr, CuNiBe, CuCoNiBe alloy etc

· Cr/Ni/NiCo/Ceramic coating etc with various shapes;

· state of the art milling, drilling, measuring & testing facilites etc with more than 20 years manufacturing experience,

in accordance with EN, DIN, ANSI, AS standards, meet strictest requirement;

· quick delivery time, 25 days or shorter;

· more than 80000 pcs capacity annually;

Detail General Size(mm):

90×90, 100×100, 110×110, 115×115, 120x120, 130x130, 135×135, 140×140, 143×143, 150x150155x155, 160×160,

165×165, 175×175, 180x180200x200, 220×220, 100×170, 100×173, 130x240, 150x200, 150×210, 150×220,

160×200, 160x220150x225, 160×235, 165×225, 175×225, 180x220,200x240, 240×240, 235×235.

Radius : 4000, 5000, 5250, 6000, 7000, 7500, 8000, 9000, 10250, 10300, 11000, 12000

Length : 700, 750, 780, 790, 800, 810, 812, 850, 900, 1000

| NAME | SIZE | CAMBER RADIUS | THICKNESS | LENGTH | REMARKS |

Square & Rectangle Copper tubes | Square 50×50~650×650 Rectangle (100-500)×650 | 3000~17000 Also straight | 6-50 | 602-1100 | With slot single taper,double taper,triple taper,quadruplicate taper,parabolic taper and varius kinds of continuous taper high effciency copper mould tubes |

| Round copper tubes | Φ110- Φ1500 | 5000-17000 Also straight | 10-50 | 602-900 | With slot double taper,quadruplicate taper,parabolic taper and varius kinds of continuous taper high effciency copper mould tubes |

Non-standard copper mould tubes Beam Blank copper mould tubes | 535-150×120-70 | 6000-14000 | 12-50 | 700-1016 | With slot single taper,double taper,triple taper,quadruplicate taper,parabolic taper |

Copper has lower hardness which leads to lower antiabrasive property. Therefore, the area at the lower part of the moulds,

where the stress increases drastically due to shells, will be more severely worn.

To increase the life time of copper moulds, CCM provides uniform mould interior surface plating with suitable hardness.

Most of the copper mould tubes for small size billet casting are not used in any casting system where there are rigid casting stream support,

therefore they are very sensitive to be worn. We use hard chrome plating to increase the life of mould tubes.

The plating thickness recommended by CCM will be controlled in the best range.

As for the coating of copper mould plates, based on our years of experience, we are able to provide Cr coating,

Ni-Cr coating, Ni-Fe coating and Ni-Cr coating to meet the demand of various customers both at home and abroad.

TP2 is a kind of material which selected by most of the steel plants.

It shows excellent heat-proof and anti-fatigue property under high temperature and it has good processing property.

(TP2(GB/T5231-2001)=SF-Cu/DHP-Cu(DIN1787)

CuAg0.1 is adding 0.08%-0.12% silver during copper ingots melting will increase the recrystallization temperature of copper by 100℃,

which will increase the heat stress and anti-abrasive property of copper mould tube interior surface,

showing better heat resistant property than TP2.

Cu-Cr-Zr is a kind of copper alloys which can be normalized by time.

It was excellent mechanical property under both room temperature and high temperature.

It has hight heat conductivity,melting point,anti-fatigue an anti heat stress properties.

Their outstanding features make it different from the previous copper alloys.It combines all good properties together.

But compared with other copper alloys,Cu-Cr-Zr is diffcult to be formed with higher products costs.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Alon jiang

- Product Category

- Copper Alloy & Profiles,Graphite Electrodes,Mining Machinery,Refractory,Steel Round Bars

- Year Established

- 2007

- Company introduction

-

LIAONING MINERAL &METALLURGY GROUP CO.,LTD is one of largest trading and manufacture company inLiaoning Province ,P.R.C.

LMM GROUP focus our services in steel making facilities involve in 4 categories:

A) EPCC projects

We provide services in Engineering, Procurement, Construction and Commissioning (EPCC) specialized in steel division. Our scope of supplies in steel making is to produce billet and bloom by continuous casting technology from scrap.

For Steel Making Plant depending on capacity and electricity condition, selection of Induction Furnace (IF) and Electric Arc Furnace (EAF) can be done. Ladle Furnace (LF) selection to enhance metallurgical refining process for quality and productive production and finally an appropriate selection of Continuous Casting Machine produces defect free billet and bloom will be incorporated for a complete steel making plant.

For Rolling mill Plant depending on shape and sizes and capacity of the customer requirement, an appropriate rolling mill will be integrated with the steel making division. Fully continuous straight rolling mill, semi-continuous mill, tandem mill, cross country mill, reversible mill or even universal mill can be integrated. Product range can be wire rod, deformed & round bar, angle bar, channel, H beam.

B) Auxiliary Plant

Another division that we are providing is auxiliary plant such as dust collecting plant, oxygen plant, water treatment plant, electrical power distribution plant etc.

C) Individual machineries and equipment:

Beside complete steel plant, customer also can source the tools, spares, and consumable from our organization. Enquiries are most welcome for Components, individual machine, consumable.

Individual machine:

Steel Plant: Induction Furnace (IF), Electric Arc Furnace(EAF), Ladle Furnace (LF), Continuous Casting machine (CCM).

Rolling Mill : Reheating Furnaces and walking beam reheating furnace, 3 Hi Roughing Mill, 2 Hi intermediate Mill, Horizontal and vertical rolling mills, start stop flying shear, product shear, cooling bed, auto stacking and bundling machine. Roll lathe, rolls notching machine etc.

D) Components and Consumables

1)Components: Copper mould tube,Rolls and Guides, mill motors, roll neck bearings, universal shaft, gear and pinion boxes, furnace water cool equipments, Arc Furnace and induction transformers etc.

Consumables such as refractory materials,mangesia carbon bricks, slide gate plate and nozzle, graphite electrodes etcAs a special company with over ten years experience in the metal industry, we are proud to offer our customers the highest quality choices and services with a wide range of consumables engineered to suit their specific needs. We sincerely build a long term and widely range of business cooperation on basis of mutual benefits. We are urgent waiting for your earlier reply.Your quick positive action in this matter and earliest response per return e-mail/fax shall be highly appreciated. Please do not hesitate to contact us!

- Main Markets

-

Germany

Germany

- Main Product

Related Products

Cold Drawn Series Aluminum Tube Pipe

_2.jpg)

Brinicle (Graphene Coated Tube & Fin Tube)

CADMIUM FREE SILVER BRAZING WELDING RODS SILVER SOLDER BARS

Phosphorus copper alloy welding rod High quality but low price

Copper/ Copper alloy pipe, fittings, flanges and stainless fittings, flanges and Nipples

China

China