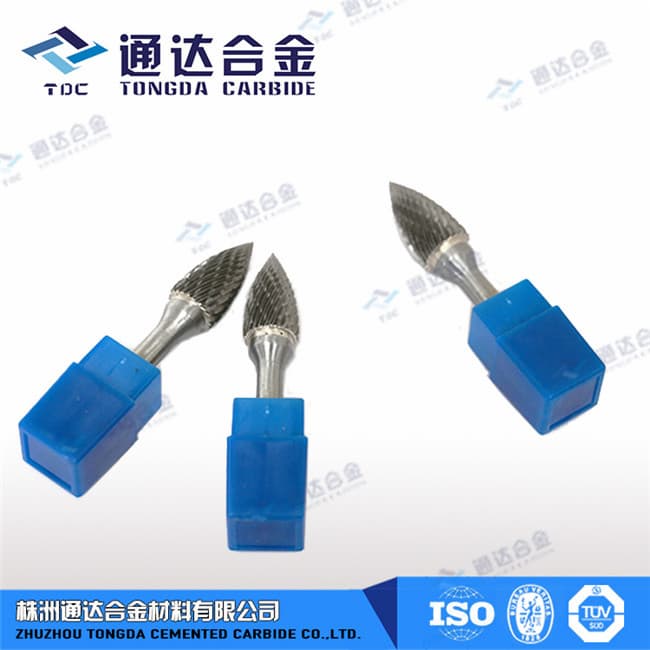

Tungsten Carbide Rotary Burrs

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- TDC

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Minerals & Metallurgy Products

Zhuzhou Tongda Cemented Carbide Co., Ltd

- Verified Certificate

-

10

| Product name | Tungsten Carbide Rotary Burrs | Certification | - |

|---|---|---|---|

| Category | Other Minerals & Metallurgy Products | Ingredients | - |

| Keyword | carbide rotary burrs , tungsten carbide rotary burrs | Unit Size | - |

| Brand name | TDC | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Tungsten carbide rotary burrs are manufactured with high precision by making use of quality checked alloys with tungsten carbide rotary burrs the aid of modern techniques by our trusted vendor's expert guidance. Offered tungsten carbide rotary burrs are in several shapes like conical, cylindrical, cylindrical ball nose, oval, flame, miniature series and special burrs as per drawing and are utilized as range tungsten carbide and tin coated types. Moreover, these tungsten carbide rotary burrs are highly demanded in industries for cutting applications.

Tungsten carbide rotary burrs are an effective way to realize mechanization in hand work operations. In the industries of airplane, ship building, automobile, machinery, chemistry etc. Tungsten carbide rotary burrs can be widely used in machining iron, steel casting, carbon steel, alloy steel, stainless steel, hardened steel, copper aluminum etc.

Tungsten Carbide Rotary Burrs Applications

1. Finish machining of all kinds of metal mold cavities after quenched.

2. Chamfering angles, circular beads and fluting.

3. Polishing impeller channels, fine grinding holes on work pieces.

4. Carving arts crafts of metal and nonmetal, etc.

Tungsten Carbide Rotary Burrs Properties

1. Machining various kinds of metal material including <=65 hardened steel.

2. Instead of small emery wheels, without powder pollution.

3. Increasing productivity of several ten times than using hand tools and theses to five times than using small emery wheels

4. Having long life of then times than high speed steel burrs and fifty times than small emery wheels.

5. Chamfering angel, circular bead or flute on the mechanical components.

6. Chamfering or burring the pipes.

7. Tungsten carbide rotary burr keep on excellent quality

8. More than 100 solid carbide burr specifications are developed to satisfy your fully professional requirement on grinding;

9. Keep the surface clean (Oil on surface have been got rid of by Ultrasonic);

10. Solid carbide burr beside different shapes, you can choose sizes, grain & length)

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- shuming

- Address

- zhuzhou,hunan

- Product Category

- Other Minerals & Metallurgy Products

- Company introduction

-

Zhuzhou Tongda Cemented Carbide Co., Ltd is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process.

All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Tongda Cemented Carbide Co., Ltd is always insisting on the business idea of “integrity industry, brand business, quality development”, and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them.

We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.

- Main Product

Related Products

API 5CT Coupling

Marine Loading Arm

Heat Resistant alloy Rubber blade v plough belt cleaner

Metal Sticker for Credit Card

Ultrafine Copper Powder (PMU) Isotope-Cu63, Cu65

China

China