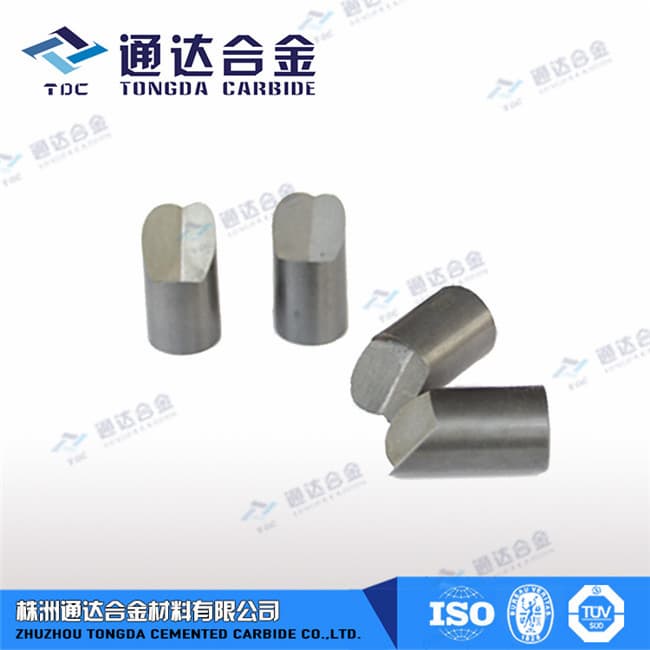

Tungsten Carbide Button

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- TDC

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Minerals & Metallurgy Products

Zhuzhou Tongda Cemented Carbide Co., Ltd

- Verified Certificate

-

10

| Product name | Tungsten Carbide Button | Certification | - |

|---|---|---|---|

| Category | Other Minerals & Metallurgy Products | Ingredients | - |

| Keyword | carbide button , tungsten carbide button , tungsten button | Unit Size | - |

| Brand name | TDC | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Tungsten carbide button is widely used as the most popular mining bits tool in modern industries, therefore, they are also named tungsten carbide mining bits, tungsten carbide button bits or just tungsten carbide mining buttons, etc. And as their material is cemented carbide, so cemented carbide buttons are also widely used among the users.

As its unique working performance, tungsten carbide buttons are widely applied to oil filed drilling and snow removal, snow plough machines or equipments.

Cemented carbide buttons are used in the coal cutter drilling tools, mine machinery tools and road maintenance tools for snow clearing and road cleaning. Carbide mining button bits are widely applied for rock tools, mining tools for use in quarrying, mining, tunneling, and civil constructions.tungsten carbide button

Types of Cemented Carbide Buttons

According to the different oil-field drilling machinery such as roller cone bits, DTH bits, geotechnical drilling tools, drifter bits, tungsten carbide mining b is divided into different standard styles : P type flat-top bits, Z type coinspherical bits, X type wedge bits.

Our advantage of making tungsten carbide button bits is that we are using HIP sintering for minimizing the porosity of carbide blank for increasing the transverse ruputure strenth (TRS). It is very suitable for high quality requirment for making carbide bottons to be ued in high and medium pressure DTH Drilling. As its unique working performance, tungsten carbide button bits are widely applied to oil filed drilling and snow removal, snow plough machines or equipments.

Cemented carbide mining bits are used in the coal cutter drilling tools, mine machinery tools and road maintenance tools for snow clearing and road cleaning. Tungsten carbide mining bits are widely applied for rock tools, mining tools for use in quarrying, mining, tunneling, and civil constructions.

According to the different oil-field drilling machinery such as roller cone bits, DTH bits, geotechnical drilling tools, drifter bits, button is divided into different standard styles: P type flat-top bits, Z type coinspherical bits, X type wedge bits.

Tungsten carbide buttons as its unique performance are widely application for oil filed drilling. tungsten carbide buttonAccording to the different oil-field drilling machinery such as Roller Cone Bits, DTH Bits, Geotechnical Drilling Tools, Drifter Bits, button been divided into different standard styles : P type flat-top bits, Z type coin spherical bits, X type wedge bits. Quality are guaranteed by our steady and higher technic.

1.Tungsten carbide button is used in the coal cutter drilling tools, mine machinery tools and road maintenance tools.

2.Tungsten carbide button are widely applied for rock tools, mining tools for use in quarrying, mining, tunneling, and civil constructions.

We offer Tungsten Carbide Buttons. All of our tungsten carbide products are made with Virgin Raw Materials and processed in HIP/Sintering unit, be of very high quality and excellent performances.

Tungsten carbide button introduction

Tungsten carbide buttons are widely applied in geological prospecting, coal mining and oil well boring. Because of its wear resistance and hardness (9.8 Moe's scale), tungsten carbide is ideally suited for wear parts, other machine parts and dies which are subject to severe service conditions, such as high temperatures, corrosion and abrasion. In recent years, tungsten carbide has emerged as a superior alternative to steel in many industrial applications.

Most of this tungsten carbide wear parts and the mining tools are made of straight WC-Co hard metals without any addition of other carbides. Fine and ultrafine grained WC hard metals have become more and more important today in the field of wear parts, tools for chipless forming and cutting tools for cast iron, non ferrous alloys and wood.

A large portion of the tungsten volume in cemented carbide is today used in wear part applications, where there is a wide range of products from the very small (such as balls for ball-point pens) to large and heavy products, such as punches, dies or hot rolls for rolling mills in the steel industry.

Properties of tungsten carbide button

1. Cemented carbide/tungsten/spherical button

2. Wearing resistance good

3. Best suited to hard rock

4. Abrasive to very abrasive

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- shuming

- Address

- zhuzhou,hunan

- Product Category

- Other Minerals & Metallurgy Products

- Company introduction

-

Zhuzhou Tongda Cemented Carbide Co., Ltd is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process.

All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Tongda Cemented Carbide Co., Ltd is always insisting on the business idea of “integrity industry, brand business, quality development”, and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them.

We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.

- Main Product

China

China