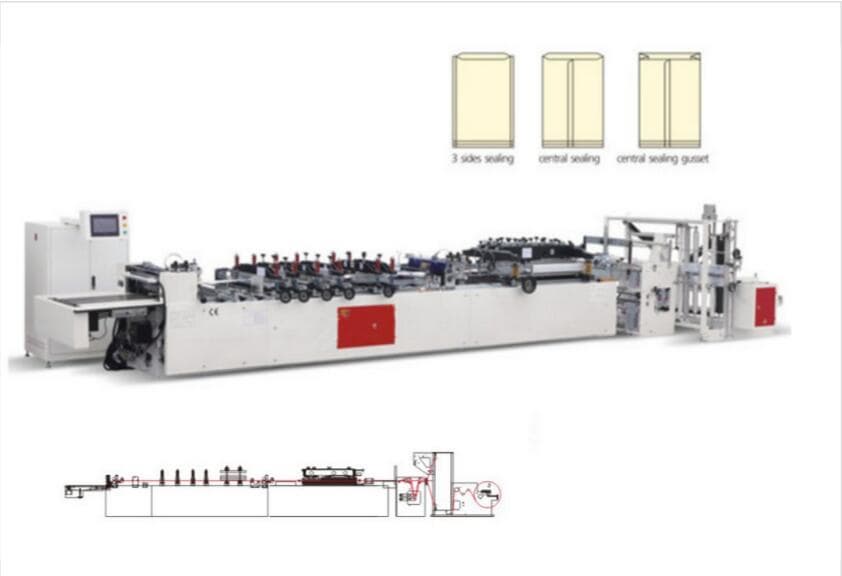

LC-400A 3 sides sealing and center sealing bag machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Printing Machines

ruian liancheng machinery factory

- Verified Certificate

-

9

| Product name | LC-400A 3 sides sealing and center sealing bag machine | Certification | - |

|---|---|---|---|

| Category | Printing Machines | Ingredients | - |

| Keyword | lc-400a 3 sides sealing and center sealing bag machine | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Technical Variables

1) Bag making function: Three side sealing bag, Center sealing bag

2) Main electric scheme: double servo motor for traction, with PLC used panasonic from Japn.,

Touch Screen from Taiwan; main driving is alternating current with yaskawa from JAPAN Transducer,

automatic constant tension for unwinding.

3) Suitable material: this machine is suitable for producing multi-layer three side sealing laminated film, plating ALU laminated film, paper-plastic laminated film, pure-ALU laminated film which takes BOPP, PET,CPP,ALU, and Nylon etc plastic laminated film as base material.

4) The speed of machine: 150 hypo-minute

5) The speed of feeding: ≤35 m/min (decided according the material)

6) The length of bag making: 50-480mm, excess this data adopts skip material feeding (Max. skip material feeding is 6) Max width :75-380mm ( after fold size of raw material)

7) The dimension of roll material: ф650*800mm , (diameter* web-width)

8) Accuracy of orientation: ≤± 0.5mm

9) Thermal-sealing knife’s quantity of heat:

1. Vertical-sealing adopts 4 groups for heating fluctuation, cooling fluctuation from up and down..

2. centra-sealing adopts 2 groups for level

3. bottom sealing adopt 3 groups heating fluctuation, 1 group for cooling fluctuation.

The quantity of temperature heating: 18 groups + 2groups free for exchange

11) The bound of temperature: 0-300 ℃

12) Total power :30 kw

13) Overall Dimension: (L*W*H) 8000X2050X12100

Weight of machine: About 3850 kg

15) Color: white of cover, white blue of fuselage+ red door

16) The type of control system: SSF-Ⅱ High speed laminating film bag making machine control system

3, Configure of Equipments, and Interrelated Variable

� Unwinding device

1) configuration: horizontal level-position (be made of magnetic powder arrester, Pneumatic Components,

Pendulum Roll, transducer, motor, traction roller, sensor and controlled system )

2) unwinding shaft: plug type and pneumatic locking device

� unwinding tension

1) Control theory: The complex constant speed tension system which is made of computer control,

magnetic powder brakes, inverter and AC motor, sensor

2) Adjustable driving: adjust through PID, drive through PWM

3) Detection method: Automatic tension monitor

� Error correct device (EPC)

1) Structure: screw adjustable by K type rack uprightness movements.

2) Driving: Solid states relay driving, low speed in-phase motor.

3) Transmission: Coupling connection

4) Type of control: centralizing controlled by double photoelectricity sensor computer

5) Detection method: Coaxial reflective photoelectric sensor

6) Tracking precision: ≤ 0.5mm

7) Round for adjust: 120mm

8) Round of photocell searching: ± 5-50mm adjustable, interval of limit switch, alarm automatically when the

photocell exceed the bound,clewing of wrong error-correct .

� Subtense

1) Structure: the center of adhesive roller two-direction rotary restructuring

2) forms: manual adjustment (adjusted handswheel)

� Up and down pictorial

1) Structure: single roller,adjustment up to down.

2) forms: manual adjustment

� Vertical sealing device

Structure: assembled-steel bridge structure

2) Driver: main motor-driven linkage

3) Transmission: coaxial eccentric organizations-vertical movement

4) Number: Group 4 (for 3 lines)

5) Length: 800mm

� Bottom sealing device

Structure: wood-beam hot pressure structure

2) Driver: main motor-driven linkage

3) Transmission: coaxial eccentric organizations - vertical movement

4) Quantity: bottom sealing Group 3, cooling Group 1

5) Length:540mm

� Films traction

1) Structure: pneumatic roller-floating structure Tension

2) Driver: Inertia Digital Servo System (Japan import, 2000T / M, Panasonic servo motor)

3) Transmission: M880-round belt drive pulley,ratio: 1:2:4

4) control forms: central control computer

5) detection approach: photoelectric sensor with integrated control Proximity Switch

� Middle Tension

1) Structure: pneumatic floating Tension roll structure

2) form of control: central control computer

3) detection approach: no-touch point close switch

4) floating roll tension adjustment bound: 0 - 0.6 MPa pressure, the middle of the guiding motor compensation

bound: 1 - 10mm (computer settings, automatic compensation)

� The main transmission device

1) Structure: crank rocker push-pull three-link structure

2) Driver: 2.2W inverter-driven, three-phase induction motor 2.2kw

3) Transmission: main drive motor with 1:10 reducer

4) control forms: Centralized control of computer

5) Exercise: main motor sports all vertical movement led frame

6) Eccentric distance: 13mm

� Automatic positioning device

1) Means:

A computer-controlled automatic precision mode precision: ≤ 0.5mm

B, reflective photoelectric sensor tracking accuracy of detection precision ≤0.5mm

2) Photoelectric searching bound: 0 - 10mm (the computer can set the size bound ,automatically search)

3) the amendment to the scope of compensation: ± 1 - ± 5mm

4) positioning that way: photoelectric encoder and servo motor feedback control computer

� Temperature Control Device

1) Detection methods: K-type thermocouple Detection

2) Control: centralized control through the computer, solid state relay driver FID adjustment

3) temperature range settings-300 degrees

4) Temperature measurement point: mid-block electric heating

� Cutter

1) Structure: up-cutter + adjustment device + fixup down-cutter

2) Form: Slide Block pneumatic roller bearing shear-top cut

3) Transmission: borrowing the eccentric shaft power

4) Adjustment: horizontal movement, pulling the handle adjustable cutting angles

� Close edge machine

1) Structure: horizontal reciprocating screw rewinding structure

2) Driver: DC motor drives

3) Control: displacement sensor

� Skip material feeding device

1) Structure: asynchronous insulated pan-pneumatic

2) form of control: central control computer

3) Driving: electronic drive solenoid switch (DC24V DC)

4) Action Means: 6 groups horizontal sealing asynchronous movement

5) times of the skip material feeding : from 2-6 times (it can be configured in the computer)

� Automatic feeding device from conveyor belt

1) Structure: 0-level position

2) Driver: solid state relay driver, gear slowing single-phase motor

3) transmission; Bevel Gear

4) distance transmission and distribution volume: computer set free

5) Control of forms: central control computer

4,ancillary facilities (users themselves)

1, Power: three phase 380V 50Hz, air Switches 150A, Ground (R.S.Y.E)

2, Capacity: ≥ 55KW

3, gas source: 35 liters / min (0.6Mpa)

4, cooling water: 15 liters / min

5,Main device of the list

Video: plesae email us for the mp4

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- sales manager

- Address

- 342-2, Zhongzhou Village, Feiyun Town ruian city

- Product Category

- Printing Machines

- Year Established

- 1984

- No. of Total Employees

- 101-500

- Company introduction

-

since 1984:Quality of survival,credibility and development,honesty for a century enterprises and brandwould rather explain the price for a while,than apology for the quality for a life!As years professional factory, the cooperated clients all know the machines from us are with quality. but a lot of new customers attracted by our machines, and after an enquiry,would say it was costly and asked why, every day there were several clients would like to do it, then i would explain it patiently for the cost and the standardMany customers think: the surface is similar, price is the king. In fact,it is a misconception. if your equipment have fault two days in three days, i think they would be lessons learned. I have two case as following,hope you can learn from themCase one:andee from the ca,he got the machine from wenzhou with very cheap price, after he visited the factory and checked the machine working, the result not as he would like, he would like to cancel the order, but the supplier refused it, so he must buy it, and now this machine have many fault, need the engineer offer the oversea serviceCase two:amir from egypt,he got the machine from jiaxing, at last he should reback the machine, and visit the china for the repair, notice:any products rebacked will be changed into the imported itemswe cannot give you the lowest price, but the high quality! if we intend to get a better profit, we can cut down the cost for the fast selling, but it will lost our promise. we will not betray our future for the short-term benefit. we adhere to strive more and more customers to be recognized and the supported.You are cordially invited to visit our company at your convenience to make a comparasion.u must be smart for more guarantee machine. no worried aftersale. we hope our user are the forward-looking person. time will prove quality is existing.

- Main Markets

-

India

India

Iran

Iran

Pakistan

Pakistan

- Main Product

Related Products

Supvan TP76E tube printer, cable id printer, wire marking

TEXTILE PRINTING MACHINE [NSHI CO., LTD]

Retort pouch

AIR950(Auto Ink Recharger)HP950,951/HP932,933

Laminating Film

China

China