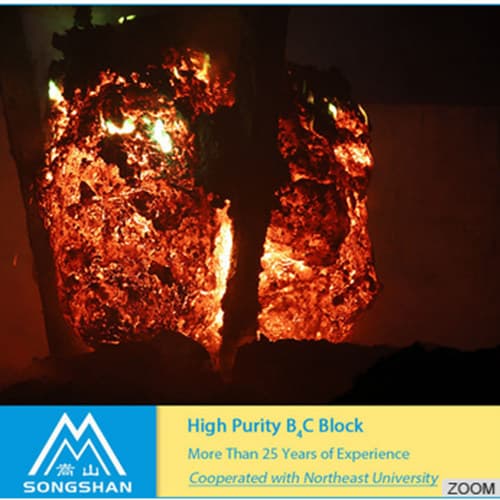

Songshan Boron Carbide for Abrasive

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Songshan

- Payment Terms

- L/C

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Abrasives

Songshan Speciality Materials Inc.

- Verified Certificate

-

9

| Product name | Songshan Boron Carbide for Abrasive | Certification | - |

|---|---|---|---|

| Category | Abrasives | Ingredients | - |

| Keyword | b4c ceramic , boron carbide ceramics , boron carbide for abrasive | Unit Size | 1.0 * 1.0 * 1.0 mm |

| Brand name | Songshan | Unit Weigh | 25 kg |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C | Shipping time | Negotiable |

- President

- Davis Kong

- Address

- Sales: 905/9F, Block D,KineerIFC , 88 Jinshui E road, Zhengzhou,China, Plant:Chuankou Industrial Zone,Daiye,Dengfeng,Henan,China

- Product Category

- Abrasives

- Year Established

- 1989

- No. of Total Employees

- 101-500

- Company introduction

-

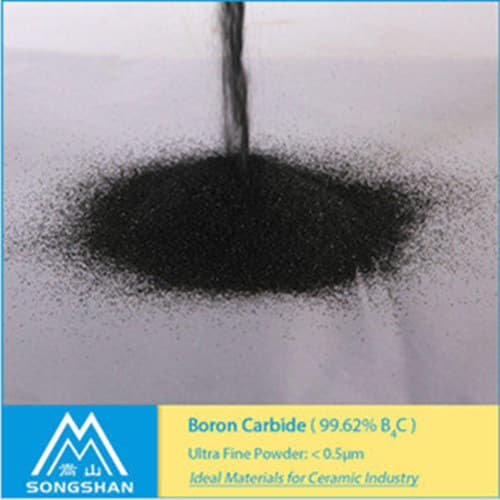

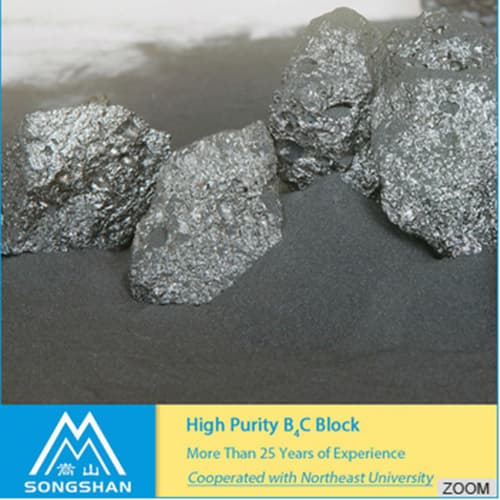

SONGSHAN SPECIALTY MATERIALS INCORPORATED is a manufacturing-type enterprise, which is ratified by the National Industrial and Commercial Bureau of China. SONGSHAN was established in 2001 on the basis of SONGSHAN Abrasive Plant of Zhengzhou Railway Industrial Group, which had been set up in 1980's.

The main products of SONGSHAN include Brown fused alumina (BFA), Boron Carbide(B4C), Silicon Carbide(SiC), Ceramic Abrasive (SG Abrasive), Compact grain abrasive & compact grain abrasive products (2 National Invention Patents), Refractory C AN is the drafter of China national standard of Corundum used as refractory (YB/T102-2007).

Quality control system has passed the ISO 9001 2000 standard certification. Company technology center has passed the ISO/IEC 17025 province/state standard certification. SONGSHAN always attaches importance to customer focus, is able to accept the orders by ISO, FEPA, JIS, ASTM standards.

Apart from entire Chinese market, SONGSHAN products have sold to Europe, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

SONGSHAN R&D Center has successfully developed Low-carbon Brown Fused Alumina, Ceramic Abrasives (SG Abrasives), Compact grain Abrasives, Nanostructured ceramic abrasive cloth, High-end Boron Carbide (used as abrasives) Compact grain abrasive cloth, Al2O3 Coated abrasive belt, SiC Coated abrasive belt, Special Material Coated abrasive belt, Zirconia Alumina Coated abrasive belt and so on.SONGSHAN Compact grain abrasive and Compact grain abrasive cloth are awarded 2 National Invention Patents (No. 201210240750.7 & 201210240753.0). During 1 year 3rd party tests, the comprehensive quality indicators of SONGSHAN compact grain abrasive products are higher than other current well-known brands 20% - 45%, but have competitive price and consistent quality, because SONGSHAN can produce raw materials, conduce to control cost and quality. SONGSHAN is the only brand who can produce Compact grain abrasive cloth in China.

Just tell us what you want,we will try our best to realize it for you.

We hope to cooperate with you in the nearest future.ement and high-end Coated Abrasives.

- Main Markets

-

Japan

Japan

South Korea

South Korea

Taiwan

Taiwan

Turkey

Turkey

U.S.A

U.S.A

- Main Product

Related Products

F12 F14 white alumina/F14 F20 white fused alumina

white fused alumina refractory metrial

Xonite Diamond Sheet

white fused alumina fine powder

_2.png)

Xonite Dendroid Brush(cleaning)

China

China