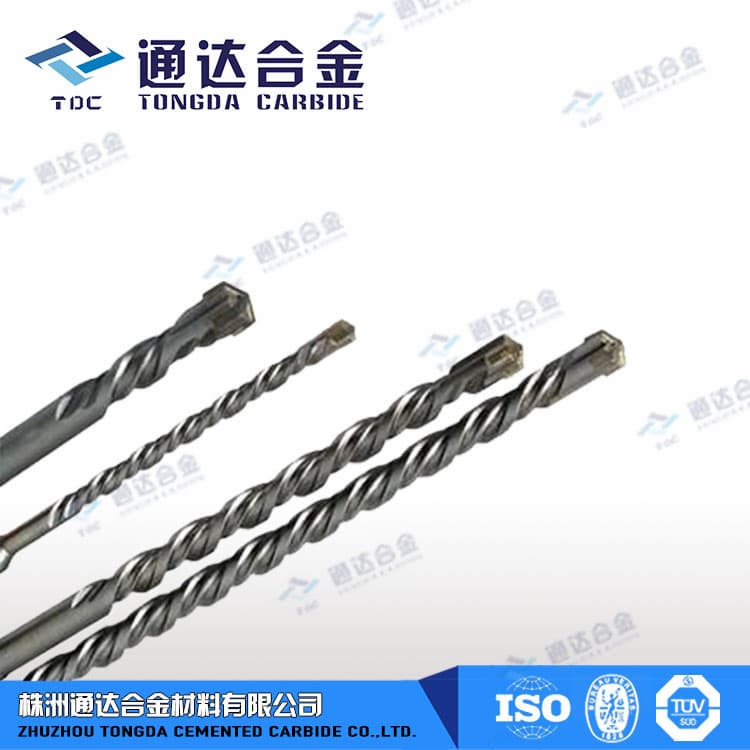

Tungsten Carbide Acicular Drill

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- TDC

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Minerals & Metallurgy Products

Zhuzhou Tongda Cemented Carbide Co., Ltd

- Verified Certificate

-

9

| Product name | Tungsten Carbide Acicular Drill | Certification | - |

|---|---|---|---|

| Category | Other Minerals & Metallurgy Products | Ingredients | - |

| Keyword | tungsten carbide acicular drill , carbide acicular drill , acicular drill | Unit Size | - |

| Brand name | TDC | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Tungsten carbide acicular drill is new technologies develop by our drilling engineering since our reform. When used in hard rock, the acicular drill is more superior to steel, which with high efficiency, good quality, low cost, low consumption of steel and other advantages. Acicular drills and diamond drilling supporting the implementation of tiered drilling, for promote small-caliber diamond drilling has important significance.

Tungsten Carbide Acicular Drill Advantages

The advantages of acicular drill include the following:

1、High Efficiency

With self grind edge features, acicular drill take many rock’s free surfaces, it is more conducive to breaking rock. Drilling in the grade of 6 to 7 rock, the efficiency is one times than conventional carbide.

2、High Quality

Aperture are rules and uniformly, drilling with small curvature. The take rate of limestone core could reach to 80%~90% in the grade of 6 to 7.

3、Long Lifetime

Φ56mm acicular drill in seven limestone formation drilling, average bit life is 9.92m, it is three to five times than normal carbide drill, and the highest life is 23.98m.

4、Less Consumption of Steel

Acicular drill is less 60% than conventional carbide in per meter drilling and abrasive costs.

5、Reused Bit Material

Low cost in the drill manufacture, a drill bit can be reused 2 to 3 times.

6、Easy To Operate

Small labor intensity, inner hole is cleaning, security is relatively good.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- shuming

- Address

- zhuzhou,hunan

- Product Category

- Other Minerals & Metallurgy Products

- Company introduction

-

Zhuzhou Tongda Cemented Carbide Co., Ltd is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process.

All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Tongda Cemented Carbide Co., Ltd is always insisting on the business idea of “integrity industry, brand business, quality development”, and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them.

We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.

- Main Product

Related Products

Raw Wool

HOT Sale Silicon Carbide Crucible for Melting Metal Aluminum

VIET NHAT STEEL Corp

Wire Rope Forming Processing Work

API 5CT Coupling

China

China