Brown Fused Alumina for coated abrasives P8-P200

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Zhongsen

- Payment Terms

- D/A,D/P,L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- abrasive, brown fused alumina, coated abrasives, aluninium

- Category

- Other Aluminum

Luoyang Zhongsen Refractory, Co., Ltd.

- Verified Certificate

-

9

| Product name | Brown Fused Alumina for coated abrasives P8-P200 | Certification | - |

|---|---|---|---|

| Category | Other Aluminum | Ingredients | - |

| Keyword | abrasive , brown fused alumina , coated abrasives , aluninium | Unit Size | - |

| Brand name | Zhongsen | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Certificate of Analysis-Brown Fused Alumina

General Information

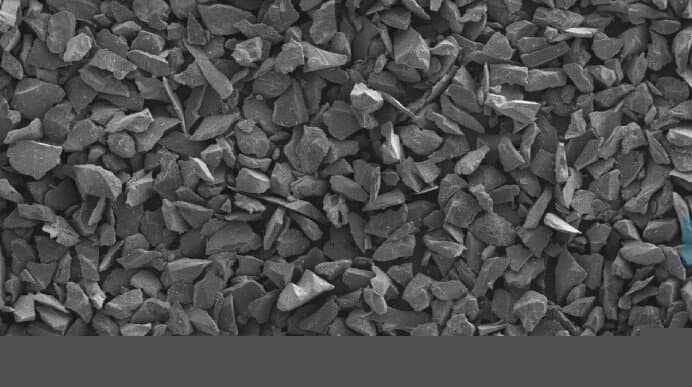

Product : Brown Fused Alumina for Coated Abrasives (Sandpaper, Sanding Belt, Polishing Pads)

Other Names : Brown Fused Aluminium Oxide, Brown Aluminum Oxide, Brown Corundum, BFA P Sizes

Country of Origin : China

Manufacturer of Material : Luoyang Zhongsen Refractory Co.,Limited

Features : Clean Material, Good Chemical Content, Good Abrasive Ability

Physical Specifications & Package

Main Content : Al2O3(Aluminum Oxide)

Specific Gravity : ≧3.90 g /cm3

Bulk Density : 1.4-2.3 kg / m3

Hardness : 9 MOSH

Color : Brown

Melting Point : 2300℃

Sizes Available : P8-F220, P280-P1500, other sizes to request

Package : Jumbo Bag, 25kg Bag and 40 Bags on a Pallet

Particle Distribution & Chemical Content

Brown Fused Alumina for Coated Abrasives

Physical Analysis | Grit# | Q1 | Q2Max | Q3 | Q4 | Q5Min | Q6Max |

P20 | +1.70 | +1.18 | +1.00 | +0.850 | +0.710 |

| |

Standard | 0% | 0-7% | 42±8% | 86±6% | 96% | 4 | |

036 | 0 | 5.5 | 41.8 | 83.7 | 98.5 | 1.5 | |

Physical Analysis | Grit# | Q1 | Q2Max | Q3 | Q4 | Q5Min | Q6Max |

P24 | +1.40 | +1.00 | +0.850 | +0.710 | +0.600 |

| |

Standard | 0% | 0-1% | 14±4% | 61±9% | 92% | 8 | |

057 | 0 | 0.1 | 12.5 | 71.9 | 97.6 | 2.4 | |

Physical Analysis | Grit# | Q1 | Q2Max | Q3 | Q4 | Q5Min | Q6Max |

P30 | +1.18 | +0.850 | +0.710 | +0.600 | +0.500 |

| |

Standard | 0% | 0-1% | 14±4% | 61±9% | 92% | 8 | |

037 | 0 | 0 | 13.5 | 70 | 94.6 | 5.4 | |

038 | 0 | 0 | 15.5 | 70 | 96.6 | 3.4 | |

Physical Analysis | Grit# | Q1 | Q2Max | Q3 | Q4 | Q5Min | Q6Max |

P36 | +1.00 | +0.710 | +0.600 | +0.500 | +0.425 |

| |

Standard | 0% | 0-1% | 14±4% | 61±9% | 92% | 8 | |

062 | 0 | 1 | 13.5 | 56.9 | 94.8 | 5.2 | |

012 | 0 | 0.9 | 14 | 54.9 | 94 | 6 | |

040 | 0 | 0 | 13.5 | 55.4 | 94.8 | 5.2 | |

066 | 0 | 0.4 | 12.5 | 55.4 | 95.3 | 4.7 | |

021 | 0 | 0.4 | 13 | 54.9 | 95.3 | 4.7 | |

Physical Analysis | Grit# | Q1 | Q2Max | Q3 | Q4 | Q5Min | Q6Max |

P40 | +0.710 | +0.500 | +0.425 | +0.355 | +0.300 |

| |

Standard | 0% | 0-7% | 42±8% | 86±6% | 96% | 4 | |

069 | 0 | 5.3 | 44.8 | 90 | 99 | 1 | |

061 | 0 | 4.3 | 44.3 | 89 | 99 | 1 | |

058 | 0 | 5.3 | 46.8 | 90 | 99 | 1 | |

059 | 0 | 5.3 | 47.8 | 89 | 99 | 1 | |

060 | 0 | 5.3 | 47.3 | 88.5 | 99 | 1 | |

Physical Analysis | Grit# | Q1 | Q2Max | Q3 | Q4 | Q5Min | Q6Max |

P50 | +0.600 | +0.425 | +0.355 | +0.300 | +0.250 |

| |

Standard | 0% | 0-3% | 26±6% | 75±9% | 96% | 4 | |

065 | 0 | 2.3 | 24.1 | 75.5 | 97.7 | 2.3 | |

Physical Analysis | Grit# | Q1 | Q2Max | Q3 | Q4 | Q5Min | Q6Max |

P60 | +0.500 | +0.355 | +0.300 | +0.250 | +0.212 |

| |

Standard | 0% | 0-1% | 14±4% | 61±9% | 92% | 8 | |

032 | 0 | 0 | 12.4 | 65.8 | 94.8 | 5.2 | |

033 | 0 | 0 | 13.4 | 69.8 | 96.8 | 3.2 | |

034 | 0 | 0 | 12.4 | 65.8 | 95.7 | 4.3 | |

035 | 0 | 0 | 12.4 | 65.8 | 95.7 | 4.3 | |

046 | 0 | 0 | 15.4 | 65.8 | 94.8 | 5.2 | |

Physical Analysis | Grit# | Q1 | Q2Max | Q3 | Q4 | Q5Min | Q6Max |

P80 | +0.355 | +0.250 | +0.212 | +0.180 | +0.150 |

| |

Standard | 0% | 0-3% | 26±6% | 75±9% | 96% | 4 | |

014 | 0 | 0 | 24.9 | 75.4 | 97.7 | 2.3 | |

067 | 0 | 0 | 24.9 | 74.4 | 97.2 | 2.8 | |

068 | 0 | 0 | 24.9 | 74.4 | 96.7 | 3.3 | |

044 | 0 | 0 | 27.9 | 78.9 | 97.7 | 2.3 | |

013 | 0 | 0 | 24.9 | 74.4 | 97.2 | 2.8 | |

Physical Analysis | Grit# | Q1 | Q2Max | Q3 | Q4 | Q5Min | Q6Max |

P100 | +0.300 | +0.212 | +0.180 | +0.150 | +0.125 |

| |

Standard | 0% | 0-1% | 14±4% | 61±9% | 92% | 8 | |

029 | 0 | 0.1 | 12.7 | 68.9 | 96.2 | 3.8 | |

027 | 0 | 0.1 | 13.2 | 65.9 | 95.7 | 4 | |

028 | 0 | 0.1 | 12.2 | 64.9 | 96.2 | 3.8 | |

030 | 0 | 0.1 | 11.2 | 65.9 | 96.2 | 3.8 | |

045 | 0 | 0.1 | 12.2 | 65.8 | 96.2 | 3.8 | |

Physical Analysis | Grit# | Q1 | Q2Max | Q3 | Q4 | Q5Min | Q6Max |

P120 | +0.212 | +0.150 | +0.125 | +0.106 | +0.090 |

| |

Standard | 0% | 0-7% | 42±8% | 86±6% | 96% | 4 | |

059 | 0 | 0 | 36 | 83.1 | 99.2 | 0.8 | |

061 | 0 | 0 | 36.5 | 83.1 | 99.2 | 0.8 | |

039 | 0 | 0 | 36 | 85 | 99.2 | 0.8 | |

031 | 0 | 0 | 36 | 85 | 99.2 | 0.8 | |

037 | 0 | 0 | 36 | 83 | 99.2 | 0.8 | |

Physical Analysis | Grit# | Q1 | Q2Max | Q3 | Q4 | Q5Min | Q6Max |

P150 | +0.180 | +0.125 | +0.106 | +0.090 | +0.075 |

| |

Standard | 0% | 0-3% | 26±6% | 75±9% | 96% | 4 | |

033 | 0 | 1 | 30.4 | 76.6 | 98.2 | 1.8 | |

060 | 0 | 1 | 30.4 | 76.5 | 98.2 | 1.8 | |

063 | 0 | 2.5 | 22.4 | 79.1 | 98.7 | 1.3 | |

038 | 0 | 2.5 | 22.4 | 79.7 | 98.7 | 1.3 | |

065 | 0 | 1.5 | 21 | 76.1 | 98.2 | 1.8 | |

057 | 0 | 1.5 | 23 | 78.1 | 98.2 | 1.8 | |

058 | 0 | 1 | 22.4 | 76.1 | 98.7 | 1.3 | |

062 | 0 | 1 | 23 | 76.1 | 98.7 | 1.3 | |

064 | 0 | 2 | 24.4 | 79.6 | 98.3 | 1.3 | |

047 | 0 | 2 | 24 | 78.6 | 98.7 | 1.3 | |

Physical Analysis | Grit# | Q1 | Q2Max | Q3 | Q4 | Q5Min | Q6Max |

P180 | +0.150 | +0.106 | +0.090 | +0.075 | +0.063 |

| |

Standard | 0% | 0-2% | 15±5% | 62±12% | 90% | 10 | |

051 | 0 | 0 | 13 | 73.6 | 95.3 | 4.7 | |

050 | 0 | 0 | 13.5 | 73.6 | 95.3 | 4.7 | |

048 | 0 | 0 | 13 | 73.6 | 95.3 | 4.7 | |

049 | 0 | 0 | 13 | 73.1 | 96.3 | 3.7 | |

046 | 0 | 0 | 13 | 73.1 | 96 | 4 | |

Physical Analysis | Grit# | Q1 | Q2Max | Q3 | Q4 | Q5Min | Q6Max |

P220 | +0.125 | +0.090 | +0.075 | +0.063 | +0.053 |

| |

Standard | 0% | 0-2% | 15±5% | 62±12% | 90% | 10 | |

054 | 0 | 0.9 | 19.4 | 67.5 | 95.5 | 4.5 | |

065 | 0 | 0.9 | 19.4 | 66.5 | 95.5 | 4.5 | |

032 | 0 | 0.9 | 18.9 | 67 | 95.5 | 4.5 | |

034 | 0 | 0.9 | 18.7 | 67 | 95.5 | 4.5 | |

036 | 0 | 0.7 | 19.1 | 66.5 | 95.5 | 4.5 | |

053 | 0 | 0.7 | 18.6 | 66.5 | 95.5 | 4.5 | |

052 | 0 | 0.6 | 18.4 | 67.5 | 95.5 | 4.5 | |

035 | 0 | 0.3 | 18 | 67 | 95.5 | 4.5 | |

055 | 0 | 0.9 | 18.7 | 67 | 95.5 | 4.5 | |

066 | 0 | 0.3 | 18.5 | 65 | 95.5 | 4.5 |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | D/A,D/P,L/C,T/T | Shipping time | Negotiable |

- President

- Luo Zhongkuan

- Address

- Registered & Main Manufacturing Address: Yaowan Village,South Dukang Road,Yichuan County,Luoyang,Henan Province,P.R.CHINA Sales Office: Jiudumingjun,Cross of Guanlin Road&Changxing Road,Luolong District,Luoyang,Henan Province,P.R.CHINA

- Product Category

- Other Aluminum

- Year Established

- 1988

- No. of Total Employees

- 51-100

- Company introduction

-

About us

Luoyang Zhongsen Refractory Co.,Limited is a China supplier of Refractory Minerals and Abrasive Grains for refractories,abrasives and blasting applications, located in Luoyang, Henan Province, which is the most important manufacturing base of Fused Minerals for various industrial sectors. Zhongsen Refractory been manufacturing and supplying Fused Minerals for Refractories,Abrasives(Boned & Coated),Blasting and Surface Preparation,Coating,Precision Casting,Anti-Slipping,Filter Media etc. Zhongsen Refractory have our own electric arc furnaces, size grading equipments, washing facilities,magnetic contents removing facilities and our own chemical and physical analysis laboratory to make sure that our products conform to various international standard and customized requirements. Main products are Fused Alumina(Fused Aluminium Oxide,Artificial Corundum) and Silicon Carbide(Black&Green) for refractories and abrasives.

Our materials are with good Chemical Content, Fine Particle Distribution, High Cleaness, Little Dust and Magnetic Contents. Our product tracking system and QC on raw materials receival, production and packing ensure the best quality.

Minerals Supplied: Fused Minerals like Brown Fused Alumina,Vice White(Sub White,Grey)Fused Alumina,White Fused Alumina,Pink Fused Alumina,Black Fused Alumina,Zirconia Fused Alumina,Single Crystal(Monocrystalline) Fused Alumina,Tabular Alumina,Black Silicon Carbide(SiC),Green Silicon Carbide; Other abrasive or blast media like Glass Beads,Garnet,Synthetic Cryolite; Other refractory minerals like Tap-hole Clay,Gunning Mud,Recarbonizer,Bauxite,Kaolin Clay etc.

Standard: China GB,America ANSI,Japan JIS,Europe FEPA and International ISO.

1, F8-F220, F280-F1500 for bonded abrasives,blasting and polishing

2, P8-P220 for coated abrasives

3,0-1mm,1-3mm,3-5mm,5-8mm,0-0.2mm,0-0.5mm,100mesh,325mesh for refractories;Mesh Sizes, Micron Sizes other other sizes according to customer request.

4, Calcined Fused Alumina(Medium & High Temperature), Second Grade BFA,Low Sodium WFA, Bamarc WFA,Dust Collector Fines of BFA,WFA,Silicon Carbide.

- Main Markets

-

Austria

Austria

China

China

France

France

Hong Kong(China)

Hong Kong(China)

India

India

Japan

Japan

North Korea

North Korea

Pakistan

Pakistan

Taiwan

Taiwan

Thailand

Thailand

- Main Product