ANTI-TARNISH TREATMENT FOR SILVER

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- copper, gold, gold plating, silver plating

- Category

- Other Chemicals

NCTBIO

- Verified Certificate

-

9

| Product name | ANTI-TARNISH TREATMENT FOR SILVER | Certification | - |

|---|---|---|---|

| Category | Other Chemicals | Ingredients | - |

| Keyword | copper , gold , gold plating , silver plating | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

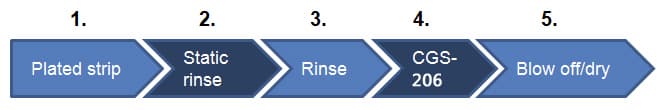

DESCRIPTION

CGS-206 is a new generation, highly effective antitarnish composition for silver, silver plated,

articles. CGS-206 is based on an aqueous, heavy metal-free and applied by simple immersion

process. Active ingredients of CGS-206 get transparent chemically covalent bond on the

precious metal surface, thereby the active sites are protected. This physiochemical interaction

in turn imparts a resistance property for sulfur or ozone corrosives.

The Self Assembled Monolayer(SAM) film is non poisonous and can safely be applied to

jewelry, ornaments, all types of flatware and holloware etc. This film hardly has any impact on

electrical contact resistance, solderability, moreover gives lubricating effect hence suitable for

electrical connectors.

The salient features of CGS-206 are :

1) Heavy metal-free

2) Solvent free

3) Chemically stable film

4) Easy to operate

5) Non hazardous

6) No effect on electrical conductivity

7) Decorative and electronics

OPERATING CONDITIONS

Concentration : 100 ml/l (range: 10-200 ml/l) CGS-206.

Operation temperature : 55°C (45-57°C). Operating temperature should strictly not exceed

60°C, otherwise bath components will be destroyed. You will see a too high temperature

because the solution becomes cloudy and opaque at temperatures above 60°C.

pH-value : Keep below 4.0 with Sulfuric acid is effective.

Agitation : Slow agitation by means of a pump and agitation of the parts is recommended.

Filtration : Not recommended, active compound might absorb on the filter.

Time of exposure : Rack/Barrel : 120 s (30-240 s) | Reel-to-reel : 10s (5-20s)

EQUIPMENT REQUIRED

Tanks : Constructed of stainless steel, polypropylene, PVC, PVDC, PP or HDPE.

Fume Extraction : Recommended.

Heaters : Preferable PTFE. Heaters must be fitted with low solution level cut outs

and an earth leakage circuit breaker.

Agitation : Preferably by agitator.

INITIAL MAKE-UP OF THE SOLUTION

1. Ensure that the tank is thoroughly cleaned before installing CGS-206.

2. Fill the tank approximately 75% with distilled or deionized water.

3. Heat the solution to the correct operating temperature.

4. Slowly add the required volume of CGS-206 concentrate and mix thoroughly.

5. Adjust to the final bath volume with distilled or deionized water.

6. Ensure that the temperature is within the correct operating range.

7. The bath is now ready to use.

NOTE

Before using CGS-206 it is recommended to melt thoroughly and stir the concentrate well. Do not

freeze. This can easily be compensated by placing the container of CGS-206 under warm

(50ºC) water till it is homogeneous. CGS-206 will become a clear yellow/orange liquid which,

after stirring/shaking can be handled easily

SOLUTION CONTROL AND REPLENISHMENT

On cooling or after a period of non use working solution may exhibit phase separation.

This will disperse again after heating the solution to the required operating temperature.

Evaporation losses should be compensated for by addition of distilled or deionized water.

The CGS-206 concentrate must be maintained at 100%.The effective inhibitor content

can be determined using the method described in APPENDIX “1. ANALYSIS METHODS for

ANTITARNISH CGS-202”.

APPENDIX

Analysis Methods for CGS-206

1. The inhibitor concentration can be determined using the following method of analysis:

Equipment : 250ml Erlenmeyer flask, Volumetric pipette, 25ml burette

Chemicals : 30% Sulfuric acid, 0.1 N iodine solution, 0.1 N-sodium thiosulfate solution PI-

5 (ask for this product at NCT)

Method : Pipet 50ml of the warm, homogeneous process solution into a 250ml

Erlenmeyer flask mixed with about 10ml PI-5 and add about 5ml sulfuric acid(30%).

Dilute this solution with 50ml deionized water. Add 10ml 0.1 N iodine solution and shake

thoroughly before the sample stands at a dark place for about 15 minutes. Titrate the

resultant red-brown solution with 0.1 N-sodium thiosulfate solution until the red-brown

color changes to the white color of the original solution.

Calculation : Concentration of CGS-206 (ml/l) = (10– consumption of 0.1 N-Na2S2O3)x6

2. Method for testing the oxidation protection of an electroplated precious metal layer:

Chemicals : 2% aqueous solution of potassium polysulfides(20g potassium polysulfides

42-45% solved in 1.0 l deionized water.) A fresh solution should always be prepared

before testing. The temperature should not > 25 °C.

Method : The test sample and the control sample will be dipped for a few minutes in a 2%

aqueous solution of potassium polysulfides, after that the parts will be rinsed in running

water. A non-passivated part is tested as a reference at the same time.

Interpretation : Perfectly passivated parts should not show any dark color changes

(spots). The control sample is used for checking the usability of the testing solution.

NOTE : Duplicate the titration as the method is critical

WASTE TREATMENT

The working solution of CGS-206 is no hazardous substance. The active ingredients can be

absorbed by active carbon and burnt with it. We recommend to stir the spent antitarnish

solution with active carbon for some hours at room temperature and to filter it afterwards. Due

to drag-in sometimes silver and cyanide accumulate in the antitarnish solution. In these cases

a treatment for the oxidation of cyanide and the precipitation of the heavy metals will be

required. The spent solution treated in this way may be discharged into the site’s sewage

system. The instructions of the local water/sewage authorities must be observed in any case.

HANDLING AND SAFETY INSTRUCTIONS

For detailed information consult the material safety data sheets for this product. Please read

material safety data sheets carefully before using this product.

ANTITARNISH CGS-206 PACKINGS

20L PE JERRY CAN, 100L PLASTIC D/M

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- kim jeong yup

- Address

- 4F,4 Yeonmujang 13-gil Seongdong-gu Seoul,korea 04783

- Product Category

- Electronics Agents

- Year Established

- 2016

- No. of Total Employees

- 1-50

- Company introduction

-

Formed in 1996, NCT company at every opportunity (create high-value market, hiding), (R&D) ,(the continuation of business), management philosophy evolved, seeking growth.

NCT succeed in localizing of antitarnishing agent at the early of days.

Due to persistent research and development, NCT has developed the antitarnishing agent for cell phone and semi conductor in the nation’s first.

The antitarnishing agent which is being produced in NCT has been used in domestic conglomerate and has been exported in china.

In the field of Biotechnology, Aryificial insemination extender for boars have been wholly relied on income items acquired permission to manufacture artificial insemination and livestock farms feeds the center.

Glass Buildings coating treament with Energy Savings in 2013,

It was selected as the development agenda of the SBA(small business association)

Also, in 2014, five years ' time that's developed the world's first oxygen The bubble type of oxygen.

O2pang to be exported and sold in the online shopping mall in China.

NCTBIO, Inc., was established in 15 January 2016 for entering a variety of

the business area

Ltd. NCTBIO the uncharted waters by building on the vision of ‘human chemistry and the environment’ toward a new challenge. Difficult, but we value our customers based on the belief we have the technology and creative, capable of living gives small but strong and customers revolutionary change we will be constant effort to be “small but strong businesses”.

- Main Product

Related Products

M-Terphenyl

CHEMICAL

Slurry Nozzle Gadget for CMP(Chemical mechanical polishing)

Lubricant(Engine Oil), Fully Synthetic, Synthetic, Mineral

Micro Slack Wax WX-160S, Microcrystalline Wax

South Korea

South Korea