Zirconia Kiln Furniture for Firing Electronic Ceramics

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- INNOVACERA

- Payment Terms

- L/C,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Ceramics

Innovacera Advanced CO.,ltd

- Verified Certificate

-

11

| Product name | Zirconia Kiln Furniture for Firing Electronic Ceramics | Certification | - |

|---|---|---|---|

| Category | Ceramics | Ingredients | - |

| Keyword | zirconia kiln plate , zirconia firing plate , zirconia setter plate , zirconia ceramic setter | Unit Size | - |

| Brand name | INNOVACERA | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | 8547100000 |

Product Information

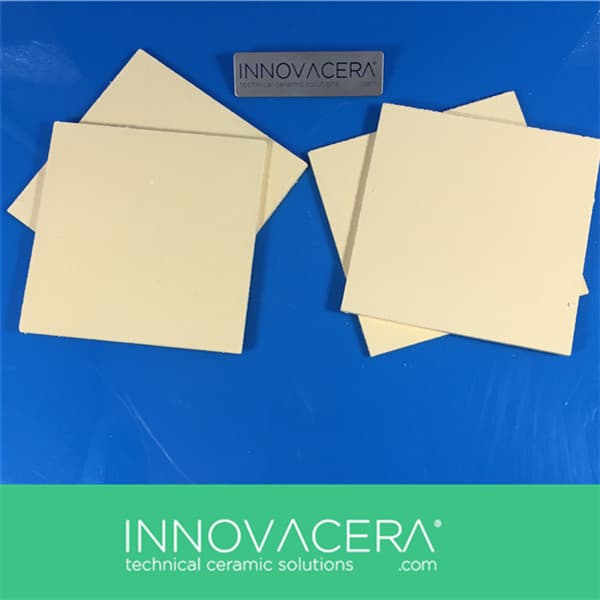

Zirconia Kiln Furniture for Firing Electronic Ceramics/INNOVACERA

Brief Introduction:

A cover plate is a porous, fired ceramic plate used to cover green ceramic parts during firing. Porous alumina and zirconia plates find use in applications such as the manufacture of SOFC and other fuel cell electrolyte substrates, MEA's, interconnects, and other fuel cell assemblies.

Features:

Composed of calcia (CaO) stabilized fused zirconia.

High-density products fired at ultra-high temperature.

Extremely low reactivity with the products being fired, because they are manufactured from very high purity raw materials.

Extremely excellent in sagging resistance, because of its specific composition, its high density and firing ultra-high temperature. (Possible to attain self-structure by themselves.)

How does it work:

The cover plate may also be used as a refractory setter liner to avoid impurities from kiln or furnace furniture such as setters, saggars, batts or boats. Setter liners extend the life of kiln furniture, for example in ferrite and thermistor manufacturing. INNOVACERA cover plates can also find use as spacers between multiple green ceramic parts in a sintered stack, thus increasing kiln loading.

Application:

For MIM stainless steel parts vacuum sintering

For technical ceramics sintering

For magnetic materials kiln using

For positive electrode materials

For electronic magnetic materials

FAQ:

1.What is MOQ?

MOQ for regular size is 50pcs.

MOQ for custome-made size is 100pcs.

2.Regular size:

75*75mm

100*100mm

114*114mm

120*120mm

250*250mm

300*300mm

400*400mm

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T,Western Union | Shipping time | Negotiable |

- President

- lalal

- Address

- Unit 4G,West Side,Lianchang bldg,No.6-8 Huli Avenue,Huli District,Xiamen,Fujian,China,361004

- Product Category

- Ball Bearings

- No. of Total Employees

- 1-50

- Company introduction

-

Innovacera offers a full range of solutions for supporting parts during sintering in reducing or oxidizing atmospheres up to 1800ºC. Innovacera has the industry's broadest range of manufacturing methods - including vacuum forming, casting, pressing and CNC machining. Mullite, alumina and alumina-zirconia compositions are available for applications in sintering of technical ceramic, electronic ceramic, and powder metal parts.

- Main Product

China

China