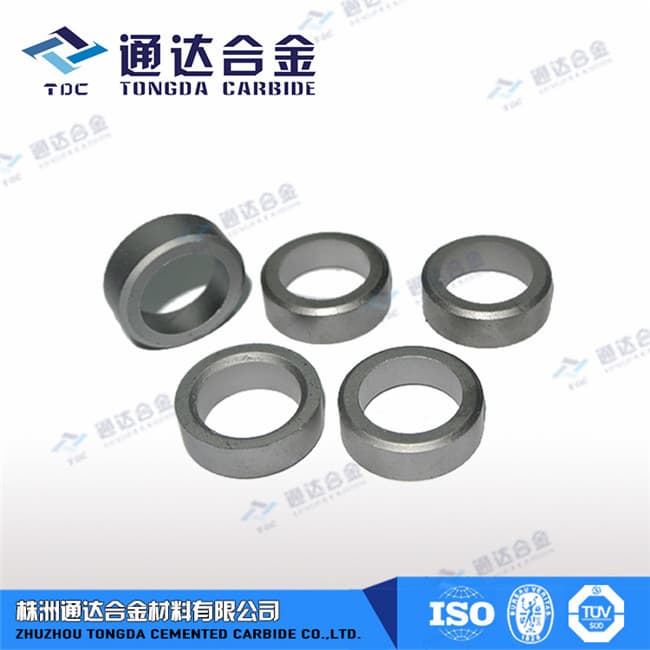

Tungsten Carbide Mechanical Seals

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- TDC

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Minerals & Metallurgy Products

Zhuzhou Tongda Cemented Carbide Co., Ltd

- Verified Certificate

-

10

| Product name | Tungsten Carbide Mechanical Seals | Certification | - |

|---|---|---|---|

| Category | Other Minerals & Metallurgy Products | Ingredients | - |

| Keyword | tungsten carbide mechanical seals , carbide mechanical seals , tungsten mechanical seals | Unit Size | - |

| Brand name | TDC | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

Tungsten carbide mechanical seals are being used increasingly on fluid pump to replace packed gland and lip seal. tungsten carbide mechanical seal Pump with mechanical seal perform more efficiently and generally perform more reliably for extended periods of time.

According to the shape, those seals are also called tungsten carbide mechanical seal rings. Due to the superiorities of tungsten carbide material, tungsten carbide mechanical seal rings shows high hardness, and the most important is that they resist corrosion and abrasion well. therefore, tungsten carbide mechanical seal rings are having wider use than seals of other materials.

Tungsten carbide mechanical seal is provided to prevent pumped fluid from leaking out along the drive shaft. The controlled leakage path is between two flat surfaces associated with the rotating shaft and the housing respectively. The leakage path gap varies as the faces are subjected to varying external load which tend to move the faces relative to each other.

The products require a different shaft housing design arrangement compared to that for the other type of mechanical seal because the mechanical seal is a more complicated arrangement and mechanical seal does not provide any support to the shaft.

Tungsten carbide mechanical seal rings come in two primary types:

Cobalt bound (Ammonia applications should be avoided)

Nickel bound (May be used in Ammonia)

Typically 6% binder materials are used in tungsten carbide mechanical seal rings, although a wide range is available. Nickel-bonded tungsten carbide mechanical seal rings are more prevalent in the wastewater pump market due to their improved corrosion resistance compared with cobalt bound materials.

In order for the tungsten carbide mechanical seal to perform over an extended time period with low frictional the mechanical seal faces are generally hydrodynamically lubricated. The fluid film will need to carry substantial load. If the load becomes to high for the film surface contact will take place with consequent bearing failure. This lubricating film is generally of the order of 3 micrometres thick , or less. This thickness is critical to the required sealing function. Tungsten carbide mechanical seal often have one face of a suitable solid lubricant such that the mechanical seal can still operate for a period without the fluid film.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- shuming

- Address

- zhuzhou,hunan

- Product Category

- Other Minerals & Metallurgy Products

- Company introduction

-

Zhuzhou Tongda Cemented Carbide Co., Ltd is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process.

All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Tongda Cemented Carbide Co., Ltd is always insisting on the business idea of “integrity industry, brand business, quality development”, and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them.

We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.

- Main Product

Related Products

API 5CT Coupling

VIET NHAT STEEL Corp

Anti loose self locking nut

Marine Loading Arm

HOT Sale Silicon Carbide Crucible for Melting Metal Aluminum

China

China