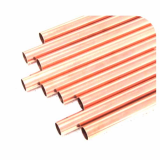

Cupronickel 90/10 tube

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Keyword

- copper nickel cu90ni10 tube, cupronickel alloy tube, cupronickel alloy pipe, copper nickel cu90ni10 tube and pipe

- Category

- Copper Alloy & Profiles

Heanjia Super-Metals Co., Ltd

- Verified Certificate

-

9

| Product name | Cupronickel 90/10 tube | Certification | - |

|---|---|---|---|

| Category | Copper Alloy & Profiles | Ingredients | - |

| Keyword | copper nickel cu90ni10 tube , cupronickel alloy tube , cupronickel alloy pipe , copper nickel cu90ni10 tube and pipe | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

The copper-nickel alloy 90/10 tubing is

manufactured by the professional manufacturer and supplier, Heanjia Super

Metals Co. Ltd. It attributed of extensively high resistance to corrosion property

and bio fouling in sea water. It is also known as Cupro nickel comprising of

nickel and more accelerated elements such as iron and manganese. It is superiorly

resistant to corrosion because the metal decay occurs under the sea water.

Specifications of Tape

|

Thickness |

1-20mm |

|

Out Diameter |

16-219mm |

Typical

Properties of 90/10 Copper Nickel Tube:-

|

Properties of some Cu-Ni alloys |

|||||||

|

Alloy |

Density |

Thermal conductivity |

TEC |

Electrical resisitivity |

Elastic modulus |

Yield strength |

Tensile strength |

|

90-10 |

8.9 |

50 |

17 |

19 |

135 |

105 |

275 |

|

70-30 |

8.95 |

29 |

16 |

34 |

152 |

125 |

360 |

Chemical

Composition ( %) of 90/10 Copper Nickel Tube:-

|

Alloy |

Name |

Copper |

Nickel |

Iron |

Lead |

|

C70600 |

90-10 copper

nickel |

~ 89 |

9.0 – 11.0 |

1.0 – 1.8 |

< 0.05 |

|

C71500 |

70-30 copper

nickel |

~ 69 |

29.0 – 33.0 |

0.4 – 1.0 |

< 0.05 |

Applications

of 90/10 Copper Nickel Tube:-

1. It is best fit for the sea water cascade fire extinguishing system. Comprising of suitable thermal conductivity

and resistance to corrosion causes by the sea water flow rates required to

establish excellent consistency due to which it is popular.

2. It is excellent for fouling on intakes and inhales screens to

restrict water flow and if separated cause clogging to heat exchangers or cause

mechanical damage to pumps and valves. Copper-nickel with its large resistance

to macro fouling can be advantageous in this application.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Jialiang Zhao

- Address

- Rong Jing Dao, Rongjing West Road, Yizhuang Technical Economic Development Area

- Product Category

- Other Machinery Parts,Other Minerals & Metallurgy Products

- Year Established

- 1984

- No. of Total Employees

- 51-100

- Company introduction

-

A professional and ISO certified manufacturer and supplier of corrosion resistant and high temperature performance metals and alloys such as Nickel,Kanthal, Inconel, Incoloy, Hastelloy, Nichrome, Nilo, Monel and Cupronickel and more are in line. We produce the alloys in the various standard forms including wire, rod, strip, pipes, sheets, tubes, bars, tape and more in the specific sizes as required by our customers. Our factory is established in China and sales office in Seattle, USA. We have worked with the diverse of industrial sectors for example aerospace, marine, automotive, nuclear, power production, pollution control and chemical engineering. Customers are assured of receiving fully tested products for their applications. Speak with our sales executive today.

- Main Markets

-

North Korea

North Korea

- Main Product

Related Products

Phosphorus copper alloy welding rod High quality but low price

COPPER WELDED

_2.jpg)

Brinicle (Graphene Coated Tube & Fin Tube)

COPPER TUBE

COPPER COPPER ALLOY PIPE FITTING FLANGE

China

China