PE(polyethylene), PP(Polypropylene)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Coating & Paint , Plastic Raw Materials , PP , PVC

COS Chem

- Verified Certificate

-

9

| Product name | PE(polyethylene), PP(Polypropylene) | Certification | - |

|---|---|---|---|

| Category |

Coating & Paint

Plastic Raw Materials PP PVC |

Ingredients | - |

| Keyword | pe , pp , resin | Unit Size | - |

| Brand name | - | Unit Weigh | - |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

PE(polyethylene), PP(Polypropylene)

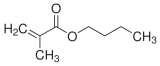

│ What is PE? │

Polyethylene is the most commonly used plastic polymer in the world with annual consumption rates exceeding 50 billion pounds per year. With a linear molecular structure of repeating –CH2-CH2-units, PE is a semi-crystalline polymer that elongates before breaking, enhancing its toughness. In general, porous PE is considered a strong, lightweight thermoplastic with strong chemical resistance.

│ What is HDPE? │

High-density polyethylene (HDPE) is available in sheets, rods, tubes and molded shapes. HDPE can be used in continuous service at temperatures up to 180°F (82°C) and intermittently at 240°F (116°C). If not stressed, it is stable at 212°F (100°C) in continuous service. HDPE Resins provide toughness, rigidity and strength for blow molding applications, extruded products, films, and injection molded items.

For blow molding, HDPE Resins offer an excellent combination of stiffness and environmental stress crack resistance, making them the materials of choice for many applications in personal care, household, industrial containers and bottle products in general. HDPE pipe resins offer the superior toughness and stress crack resistance essential for pipe extrusion, while high molecular weight HDPE film resins provide toughness and downgauging capabilities. Applications include thin gauge carrier bags, bin liners and refuse sacks.

For injection molding, HDPE Resins offer both strength and processability - the two properties that every injection molding processor wants, but rarely achieves at the same time. And this advantage is available across the wide spectrum of end-use applications.

│ Applications │

-packaging

-thin gauge carrier bags, bin liners and refuse sacks.

│ What is PP? │

Polypropylene (PP) is a thermoplastic. It is a linear structure based on the monomer CnH2n. It is manufactured from propylene gas in presence of a catalyst such as titanium chloride. Beside PP is a by-product of oil refining processes. Most polypropylene used is highly crystalline and geometrically regular opposite to amorphous thermoplastics, such as polystyrene, PVC, polyamide, etc., which radicals are placed randomly.

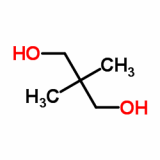

│ Characteristics │

-low density compared to other materials

-minimal moisture absorption

-excellent chemical resistance, even to solvents

-highly corrosion resistant

-relatively high superficial hardness

-very good electrical insulator

-sensitive to cold

│ Applications │

-packaging and labeling,

-textiles (e.g., ropes, thermal underwear and carpets)

-stationery

-plastic parts and reusable containers of various types

-laboratory equipment

-loudspeakers, automotive components, and polymer banknotes

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- Alex Kim

- Address

- (Siksadong, Dongguk Univ. Industrial-Academic BLDG.) No. 324, Dongguk-Ro 32, ILsandong-Gu, Goyang-Si, Gyunggi-Do, Korea

- Product Category

- Coating & Paint,PP,PVC,Plastic Raw Materials

- Year Established

- 2015

- No. of Total Employees

- 1-50

- Company introduction

-

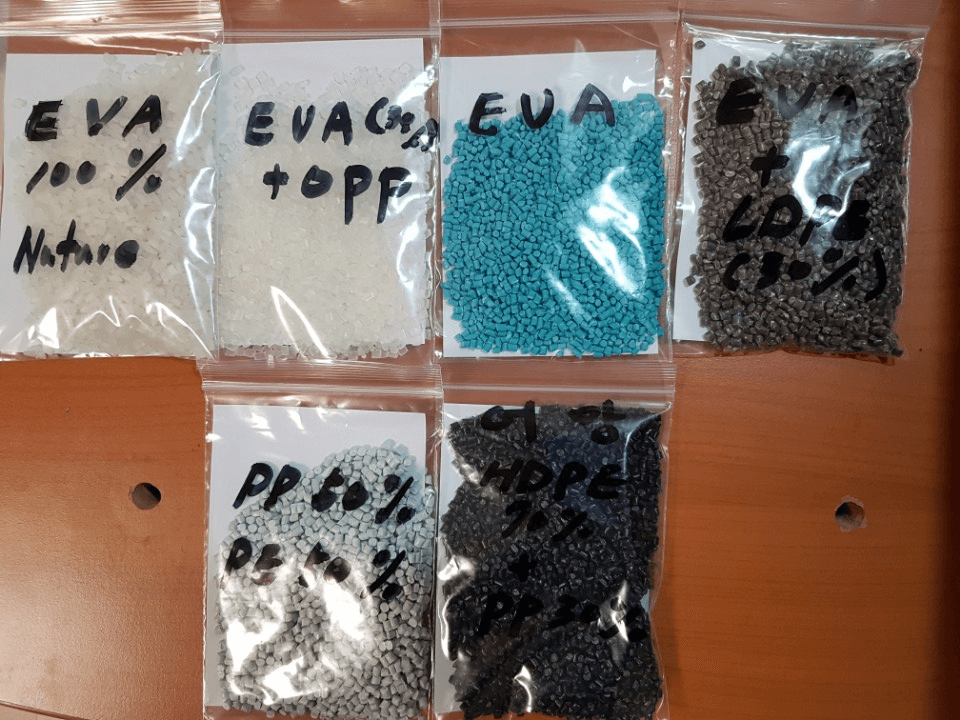

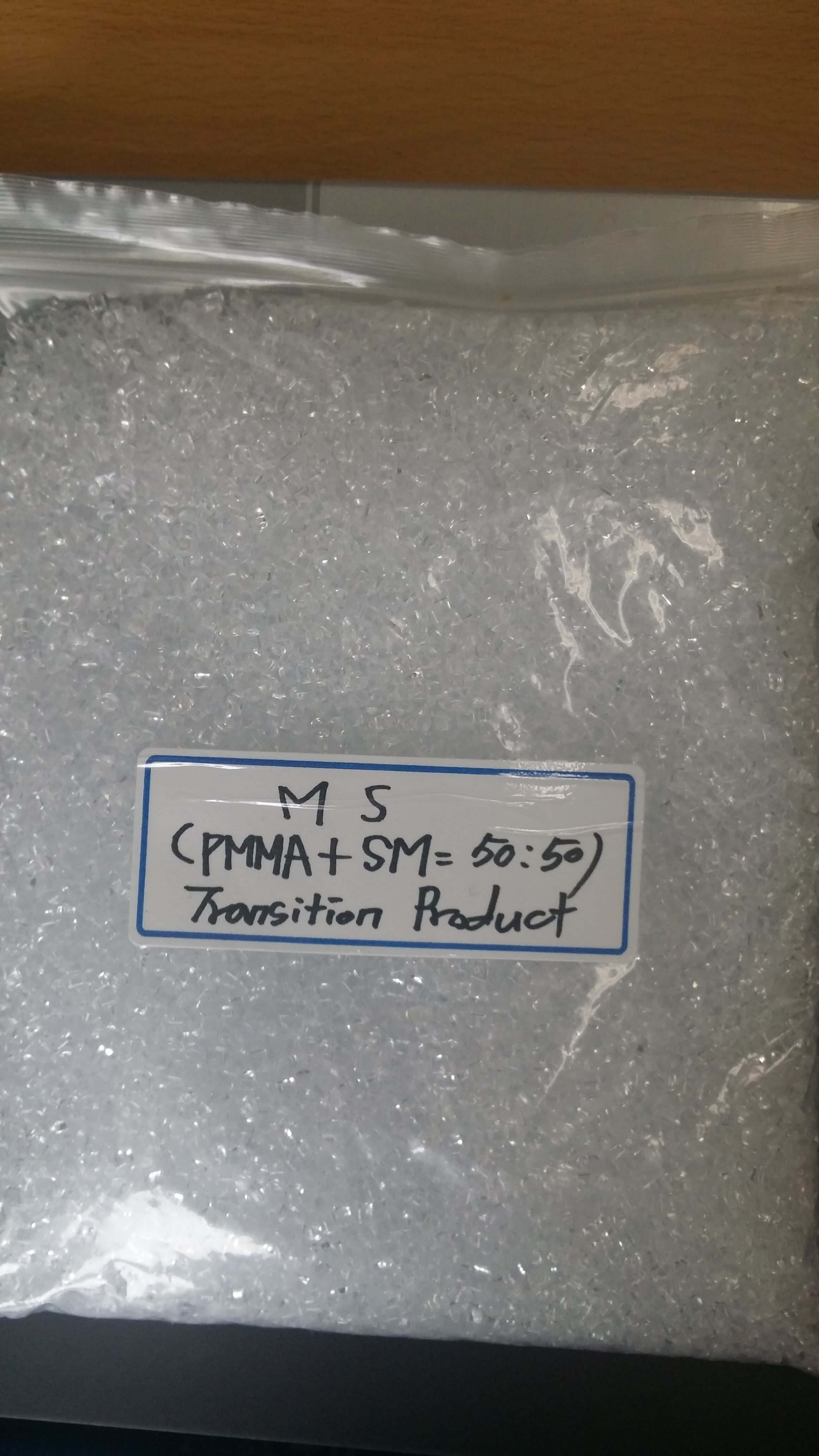

<p>COS CHEM as a agent of LG CHEM under the goal of becomming global plastic export company started its business in 2015. With our main products; PVC Stabilizer, AA, PE, PP, PVC, ABS, PS, Recycled Resin(PE, PP, EVA) and PVC plasticizer and PVC & PET sheet. We are now mainly doing business with Indian and Chinese plastic company and trying to expand our market all over the world.

Alex Kim who had worked as a main member of LG Chem has abundant experience about plastic market and business. And had put the all the know-how into COS Chem.

Currently, COS CHEM is co-operating with LG Chem, Woochang Chem, KP Tech. We would like to provide our customers the best bridge to the broad market of Korean plastic.

- Main Markets

-

China

China

India

India

Myanmar

Myanmar

Viet Nam

Viet Nam

- Main Product

Related Products

RC Level Rod

LDPE Film Scraps

Thermoplastic C5 hydrocarbon resin For Hot Melt Adhesive

Eco-Friendly Soon and Soo paint

Ldpe Film Plastic Scrap

South Korea

South Korea