Color steel insulation board making machine

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Yada

- Payment Terms

- T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Jinan Yada Automation Equipment Co.,Ltd

- Verified Certificate

-

10

| Product name | Color steel insulation board making machine | Certification | - |

|---|---|---|---|

| Category | Construction Material Making Machinery | Ingredients | - |

| Keyword | color steel roll forming machine , insulation board making machine , insulation board equipment , copor steel making machine | Unit Size | - |

| Brand name | Yada | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

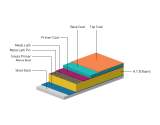

Product Information

Quick Details

|

Condition: |

New |

Type: |

Tile Forming Machine |

Tile Type: |

Color steel tile |

|

Use: |

Roof wall, step tile |

Place of Origin: |

|

Brand Name: |

Yada |

|

Model Number: |

YD-CGWSB |

Power(W): |

5.5KW |

Voltage: |

380V |

|

Dimension(L*W*H): |

10m*1.35m*1.51m |

Weight: |

8T |

Certification: |

CE&BV |

|

Warranty: |

12month |

After-sales Service Provided: |

Engineers available to service machinery

overseas |

|

|

Packaging &

Delivery

|

Packaging Details: |

usually one new type of glazed tile roll forming machine loaded in one

40GP container |

|

Delivery Detail: |

about 45 days per new type of glazed tile roll forming machine |

1. Main Accessories:

Decoiler (manual

or hydraulic for options) 1set

Feeding

device 1set

Hydraulic

step press device 1set

Hydraulic

cutting device 1set

Hydraulic

Station 1set

PLC

computer control system 1set

2m Run Out

Table(auto stacker for options) 2set

2. Main Technicial Parameter:

|

1 |

Inner

diameter of manual decoiler |

500mm |

|

2 |

Outer

diameter of manual decoiler |

1200mm |

|

3 |

Weight

capacity of manual decoiler |

5T |

|

4 |

Appearance

Size |

10000mm*1350mm*1510mm |

|

5 |

Raw Material |

colored steel or

galvanized steel |

|

6 |

Roller material |

high grade 45# forged

steel, polished, heated, quenched |

|

7 |

Blade Material |

CR12 with polished, heated

and quenched HRC60-62 |

|

8 |

Chrome Coating |

coated with 0.05mm hard

chrome |

|

9 |

Control System |

PLC control |

|

10 |

Main Motor Power |

5.5 KW |

|

11 |

Hydraulic Power |

4 KW |

|

12 |

Roller station |

16 rollers |

|

13 |

Material of chain |

high grade 45# steel: polished,

heated, quenched HRC 45-50 |

|

14 |

Speed of Product |

3-4m/min |

|

15 |

Thickness range |

0.3-0.6mm |

|

16 |

Type of cutting |

hydraulic cutting |

|

17 |

Coil Width |

914mm(max1250mm,or as

your requirement) |

|

18 |

Cover Width |

800mm(or as your

requirement) |

|

19 |

Material of rack |

complete welded

structure of A3 steel plate |

|

20 |

Machine frame stand |

welded with 36# I-steel |

|

21 |

Type of forming machine |

single station with chain

transmission |

|

22 |

Thickness of frame |

18mm |

|

23 |

Shaft Diameter |

80mm |

|

24 |

Weight |

about 8T |

|

25 |

Voltage |

380V 50HZ 3Phases( or

as your local requirement) |

|

26 |

Electrical control |

PLC frequency control

system with touch screen in English |

3. Work

flowing:

Decoiling

-- Feeding guide -- Roll forming -- Press step -- Hydraulic cutting -- Running

out

4. Payment Term

and Condition:

Payment Term: 30% T/T in advance, 70% T/T before shipment

Delivery

Time:Within 45 Working Days after receipt of

the down payment

Warranty 1 year and life-long maintenance

Installation and commissioning :Our engineer will go to make installation

there,buyer pay our engineer 100USD/day,and provide accommodation,visa and the

round-trip ticket fee

5、Usage

1、 It is widely used in load bearing roof and

buttree of large and medium-size industrial and civilian buildings

2、Like factory, workshop , garage, warehouse, locomotive

shed, hanger, exhibition building, cinema, theatre, stadium, garden etc

3、They are widely used as the supporter of roof and wall in large-scale and mid-scale

construction

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | T/T | Shipping time | Negotiable |

- President

- jiaoshouliang

- Address

- NO.8 Wenquan Road Lixia district Jinan city

- Product Category

- Manufacturing & Processing Machinery Agents,Other Machinery & Industry Equipment

- Year Established

- 1998

- No. of Total Employees

- 101-500

- Company introduction

-

Jinan Yada Automation Equipment Co.,Ltd Specializing in the production of phenolic insulation board product line, polyurethane insulation board equipment, sandwich board equipment, polyurethane, phenolic industrial equipment, such as polymerization like, can finish the polyurethane insulation board, phenolic insulation board, phenolic products during the process of manufacturing and processing.A sandwich board equipment, continuous production line for sandwich board series, insulation board.equipment, filling machine series, polyurethane, foaming machineseries, baking-free brick machine series and auxiliary machinery.And can undertake factoryto meet the needs of users design and whole plant equipment.

- Main Markets

-

Austria

Austria

Canada

Canada

China

China

France

France

Japan

Japan

North Korea

North Korea

Singapore

Singapore

South Korea

South Korea

Taiwan

Taiwan

U.S.A

U.S.A

- Main Product