Automatic Mold Temperature controller Auto Master

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- South Korea

- Brand name

- Auto Master

- Payment Terms

- L/C,T/T

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

Masang Machinery Co., ltd.

- Verified Certificate

-

9

| Product name | Automatic Mold Temperature controller Auto Master | Certification | - |

|---|---|---|---|

| Category |

Plastic Product Making Machinery

Plastic Rolling Machinery |

Ingredients | - |

| Keyword | automatic mold temp controller , south korean mold temp controller , water based mold temp controller , fuzzy and pid technology | Unit Size | 500.0 * 780.0 * 850.0 mm |

| Brand name | Auto Master | Unit Weigh | 95 kg |

| origin | South Korea | Stock | - |

| Supply type | - | HS code | - |

Product Information

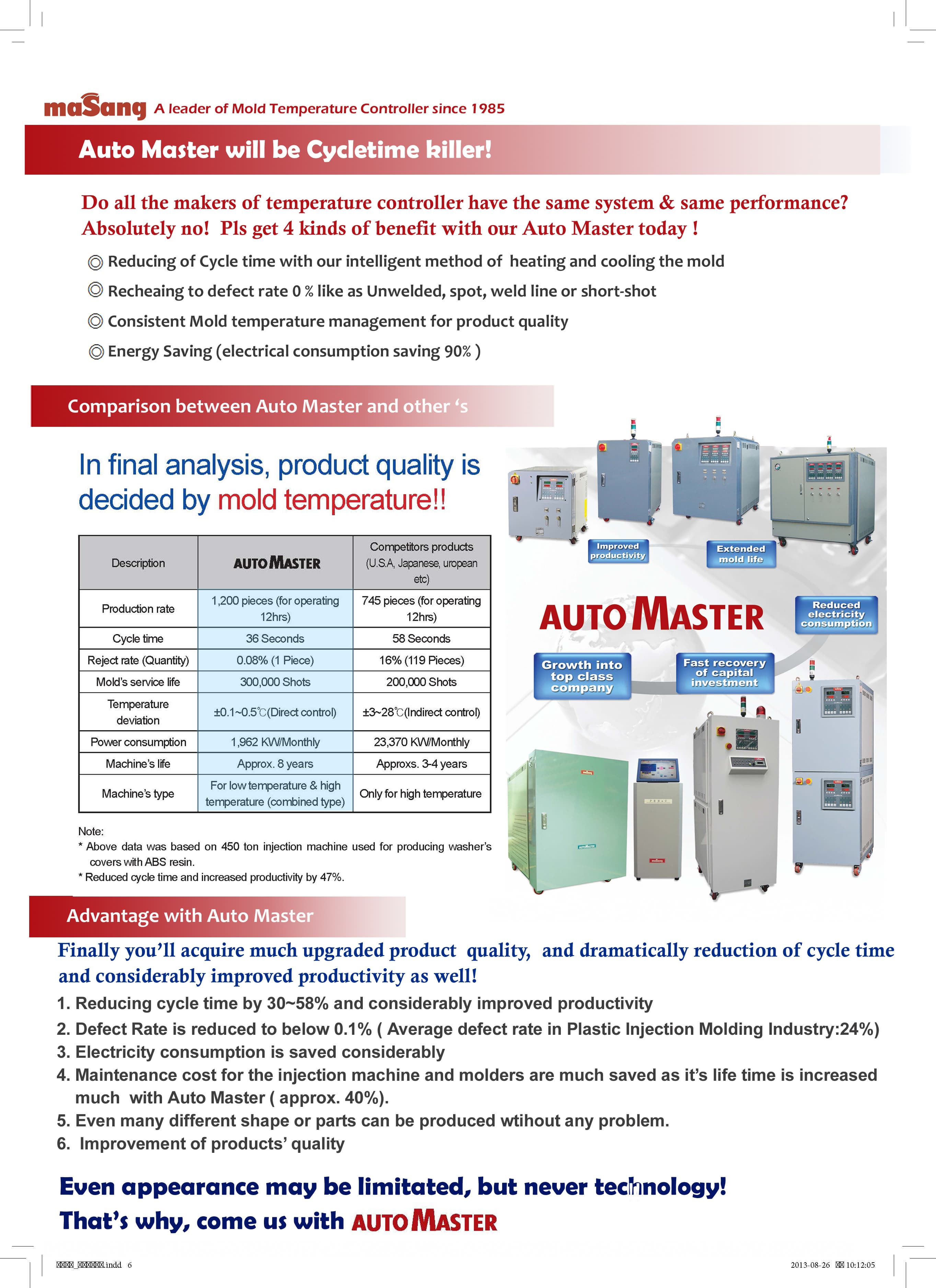

If you’re still using the Injection Molding Machine without mold temperature controllers or the machine with conventional mold temperature controllers, you may suffer from a delay of cycle time (prolonged cycle time) and many defective goods ,resulting in huge loss of monetary valve including enormous waste of plastic resins and electricity.

However, you’ll experience dramatically reduced defect rate and much improved productivity along with upgraded the no.1 branded image after applying our Automaster for your injection molding. The profits generated form it will be huge for the common problems related to injection molding will surely disappear.

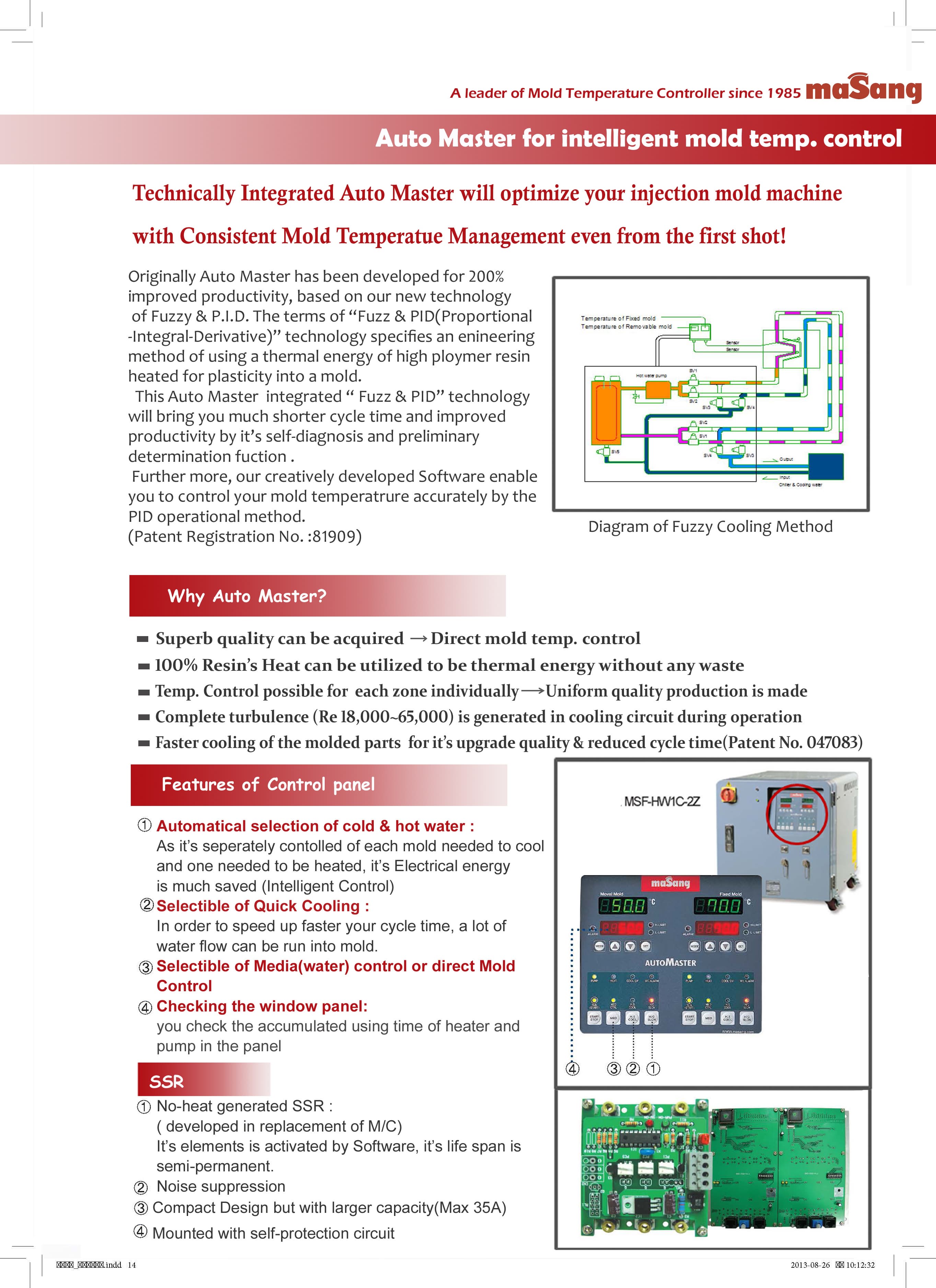

As Auto Master is our brand name of Automatic Mold Temperature Controller with high performance and accurate temperature controlling in mold, for your injection molding, to reduce the Cycle time, improved productivity with excellent quality.

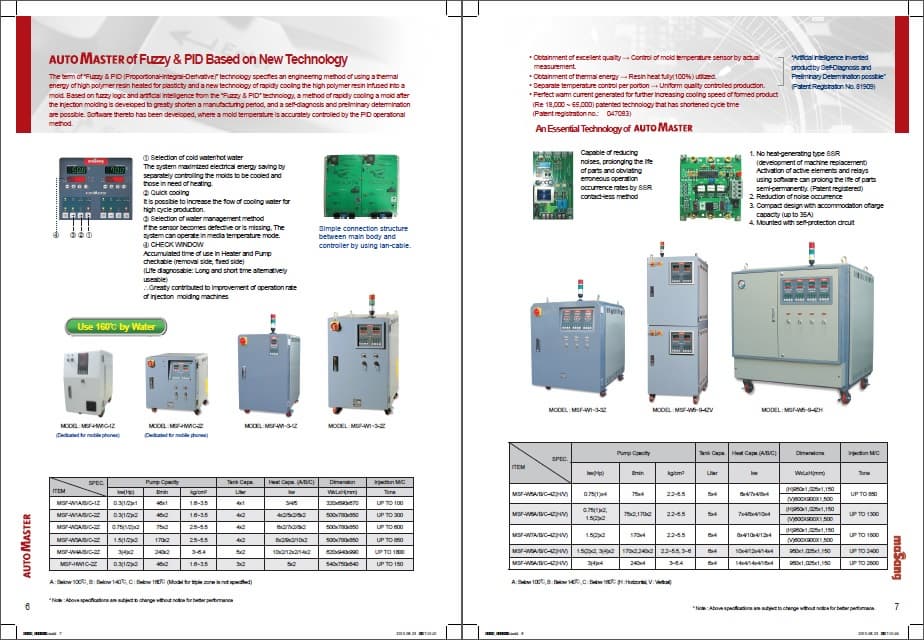

Actually as our Auto Master is operated by Fuzzy & P.I.D. technology, it’s been proved that you could save electricity up to 90% compared with the existing mold temperature controllers, which is illustrated as follows;

Item : 450Ton Injection Machine (Toggle type) in Korea.

= Motor : 55kW/Hr + Heater: 30kW/Hr ( Normally 50% operated, so 15kW/Hr) →

▶Electricity Consumption per 1 EA : 2,016kW/month, 24,192kW/year = 70kW/Hr * 12Hr * 24day/month

As above, countrywide if thousands and millions of your injection machines in your country would be working with our Auto Master, it could save significant electricity consumption as much as the energy saving of a few power stations in a year, plus you will be able to join the trend of green life, like as CO² emission suppression, significant Energy saving, dramatically improved productivity and the superb quality.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T | Shipping time | Negotiable |

- President

- Lim, Chae-bok

- Address

- 508-7, Tangjeong-dong, Kunpo-city, Kyunggi-do

- Product Category

- Plastic Product Making Machinery,Plastic Rolling Machinery

- Year Established

- 1995

- No. of Total Employees

- 1-50

- Company introduction

-

1.We’re a leading manufacturer of Automatic Molding Temperature Controller (MTC) with R & D in house through our 30 year’s engineering experience in this field since 1985. We’re not only a maker but also provider of total consulting service to our customers in this fied.●2.As we are told to be No. 1 maker, our MTC have been continuously supplied to Korea’s big companies, Samsung, LG, Hyundai Automotive up to now and acknowledged on it’s stable and high quality. That’s why we are so proud we could contributed them to be upgraded as a world major leading brand.●3.Since we have high comprehensive understanding in mold’s cooling and heating system and method, we’ll provide you our total consulting in order to improve your effective productivity.●4.We’ll continuously make development of MTC to improve your injection molding technology and always upgrade our products for your material’s saving, cycle time reducing and the better productivity as No. 1 maker of molding temperature controller in the world.

- Main Markets

-

Japan

Japan

- Main Product

South Korea

South Korea