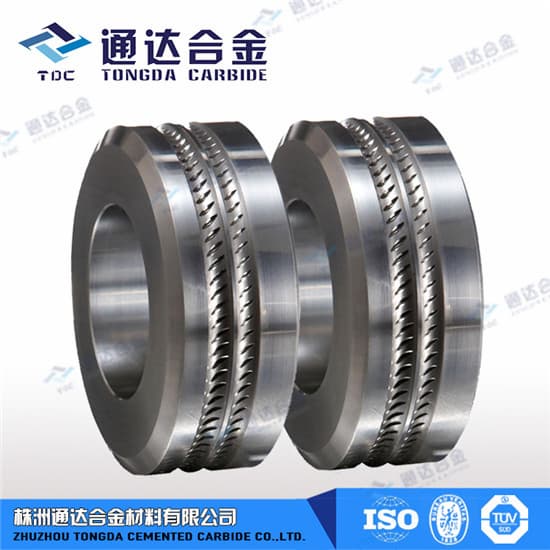

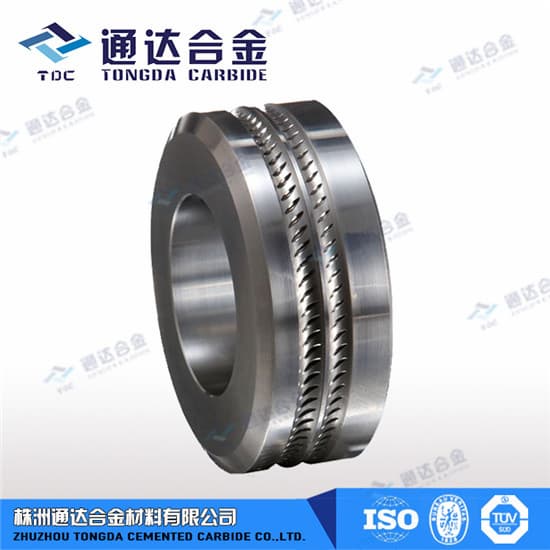

Tungsten Carbide Roller(hot roller)

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- Austria,Canada,China,North Korea,U.S.A

- Brand name

- Tongda

- Payment Terms

- Negotiable

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Other Minerals & Metallurgy Products

Zhuzhou Tongda Cemented Carbide Co., Ltd

- Verified Certificate

-

10

| Product name | Tungsten Carbide Roller(hot roller) | Certification | - |

|---|---|---|---|

| Category | Other Minerals & Metallurgy Products | Ingredients | - |

| Keyword | hot roller , carbide roller , tungsten carbide roller , carbide roll | Unit Size | - |

| Brand name | Tongda | Unit Weigh | - |

| origin | Austria,Canada,China,North Korea,U.S.A | Stock | - |

| Supply type | - | HS code | - |

Product Information

Tungsten carbide roller has characteristics of good wear resistance, high temperature red hardness, thermal fatigue resistance and thermal conductivity and high strength , have been widely used in high-speed wire rod, bar, rebar, seamless steel tubes, etc. Domestic production of tungsten carbide roller materials mostly WC- Co, WC- Co- Ni- Cr two series, and the content of Co, Co- Ni - Cr is in the range of 6wt% ~ 30wt%. From the use of perspective, tungsten carbide rollers has good mechanical properties, its flexural strength up to 2200 MPa or more, shock toughness up (4 ~ 6) × 10^6 J/ m^2, Rockwell hardness (HRA) is up to 78 to 90, widely in the high-speed wire rod rolling process, which is much higher than single-slot chilled cast steel or high speed steel rolls.

Tungsten carbide is made of tungsten carbide powder and binder phase (such as drilling, nickel, etc.), and then pressing and sintering, regardless of the conditions under cold rolled or hot rolled has excellent wear resistance, tungsten carbide rollers has been widely used in pre-finishing mill and finishing of high-speed wire rod currently. On the performance of tungsten carbide roller in hot-rolling wire rod , the material must meet the following requirements:

1. Sufficient anti-fracture strength;

2. Good abrasion resistance;

3. The smooth surface finish;

4. Excellent corrosion resistance, thermal fatigue, thermal cracking performance.

Tungsten carbide roller rings can working in bad conditions , small profile rolling (especially rebar rolling) process conditions is harsher than the high-speed wire rod, and therefore corresponds to the profile rolling ,tungsten carbide rollers recommend using high binder phase carbide.

Tungsten carbide roller material design

Pre-finishing all vehicles roller should ensure its high toughness, strength, rigidity and thermal conductivity, followed before considering its wear resistance. When designing each vehicles roller, pre-finishing materials should choose carbide grades of Co, Co- Ni- Cr binder content is high (greater than or equal to 25wt%) , requiring an average WC grain size of coarse (5μm ~ 6μm), to obtain a higher shock toughness, proper strength and hardness. For the finishing of the roller movements, particularly the last two rollers of the finish rolling, which suffered load is small, and high relative velocity of the material to be pressed (80 m / min ~ 120 m / min). In this case, the wear resistance of the roller to be the most important requirements, and must ensure the strength , timpact toughness and hardness of a reasonable match, so the binder of Co / Ni content ratio and the average grain WC control of particle size and other factors must have greater control in front of different pre-finishing rolling roll.

Tungsten carbide roller category

According to the structure of tungsten carbide rollers, it can be divided into solid tungsten carbide roller and composite tungsten carbide roller. Solid tungsten carbide rollers have been widely used in pre-finishing and finishing stands high speed wire rod mill (including fixed reducing the rack, pinch roller rack). Composite tungsten carbide roller is made of cemented carbide and other materials, and it can be divided into tungsten carbide composite roll rings and solid tungsten carbide composite roller. Tungsten carbide composite roll rings mounted on the roller shaft; solid tungsten carbide composite roller will be directly cast in the roll axis to form a whole, a large load is applied to the rolling mill.

Tungsten carbide roller production process control

Tungsten carbide rollers produced by powder metallurgy method, the key to its process control is the chemical composition of the material and the mixture was prepared, pressed molding, sintering and deep processing and other preparation process parameters.

1. Preparation of starting material (WC focus quality): As the WC raw material and quality control of the use of different levels of quality may fluctuate, resulting in adverse effects on microstructure.

2. Preparation of the mixture: Mixture preparation is the key to the production process of the roller, the roller of failure modes - trachoma, mainly generated by this procedure.

3. Pressing: roller pressing is an important process of the roller mill.

4. Sintering: roller sintering is to determine the final quality of the roller production processes, use of advanced low-pressure sintering technology, HIP sintering technology can greatly improve the performance of roller.

5. Deep processing: deep processing rollers have a greater impact on the quality and accuracy of the roller surface.

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | Negotiable | Shipping time | Negotiable |

- President

- shuming

- Address

- zhuzhou,hunan

- Product Category

- Other Minerals & Metallurgy Products

- Company introduction

-

Zhuzhou Tongda Cemented Carbide Co., Ltd is a professional company which is contributed to study and manufacturer and serve carbide wear-resistance material. For many years, our company rely on progressive production equipment and strong technician strength, constantly studying advanced technology from Switzerland, Germany and America, etc. Combining the valuable feedback from customers, taking advantage of local tungsten carbide and ceramic material, has developed various grinding and dispersion parts which had been reached domestic first-class grade.

Our tungsten grinding rotor, pegs, dispersing tray, tungsten carbide dynamic and static ring, cone round turbo, are mainly used to coating, printing, painting, dying and on the equipment of oily product grinding and dispersion process.

All our products were best-sold to twenty more provinces in China, which not only help to solve manufacturer problems for customers sale, but also be honored as foreigner replacement by many customers.

Zhuzhou Tongda Cemented Carbide Co., Ltd is always insisting on the business idea of “integrity industry, brand business, quality development”, and paying attention to the enterprise image and own brand construction. We keep a close relationship with all customers, and consider every client as a mentor, constantly strengthen the communication and cooperation, and provide the perfect service for them.

We focusing on providing the most effective solution for customers, are supposed to be a professional and diversified hard alloy manufacturer. We not only offer the standard products, but also make all kinds of customized proposal to meet customers needs together with customers themselves.

- Main Product

Related Products

Semiconductor Wafers

API 5CT Coupling

Ultrafine Copper Powder (PMU) Isotope-Cu63, Cu65

VIET NHAT STEEL Corp

Marine Loading Arm

China

China